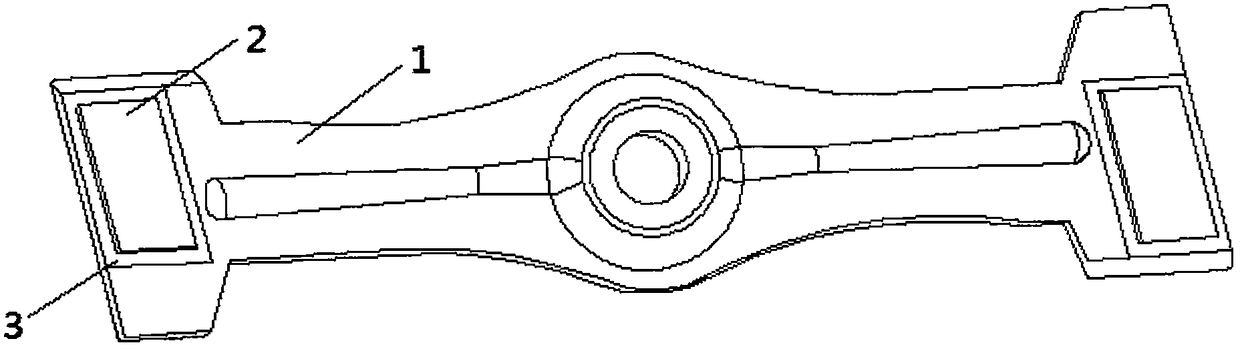

A kind of lawn mower cutter preparation method

A lawn mower and knife technology, applied in the field of lawn machine tool preparation, can solve the problems of destroying blade strength and toughness, high cost of pressure welding, long heat preservation time, etc., to improve production efficiency, small stress and deformation, workpiece structure and mechanical The effect of small changes in performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0018] The embodiment of the present invention provides a kind of lawn mower cutter preparation method, comprises the following steps:

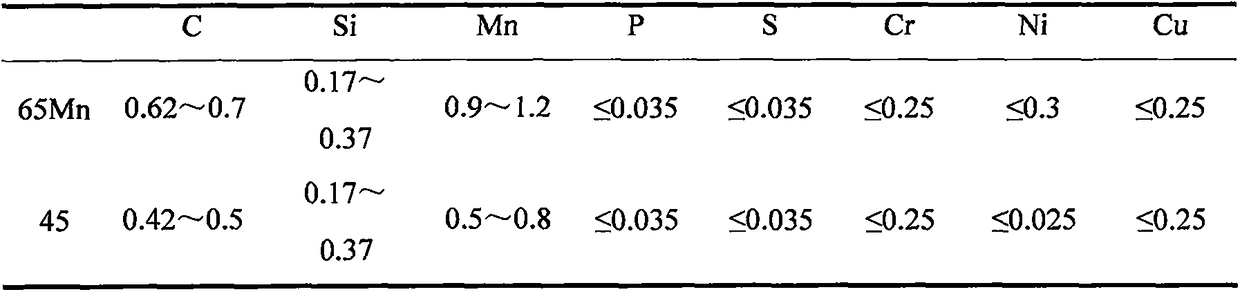

[0019] S1. Before brazing, ensure the strength of the 65Mn blade body and the toughness of the 45 steel blade matrix, and ensure that the hardness of the 65Mn material is not lower than 62HRC, and the hardness of the 45Mn material is not higher than 40HRC; the chemical composition of 65Mn and 45 steel is shown in Table 1.

[0020] Table 1 Comparison of chemical composition between 65Mn and 45 steel

[0021]

[0022] S2. Put the phosphor copper filler metal on the surface of the 45 steel blade substrate for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com