Combined processing method for preparing anti-corrosion AZ91D magnesium alloy with obdurability

A combined processing and magnesium alloy technology, applied in the field of alloy processing, can solve problems such as poor corrosion resistance, and achieve the effects of improving the film forming process, increasing the yield and good industrial application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

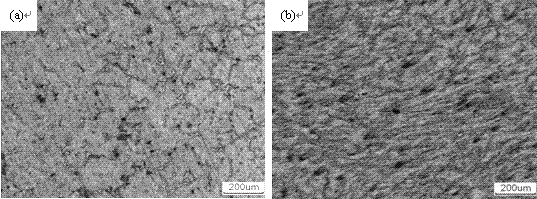

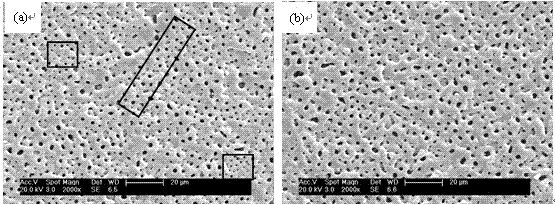

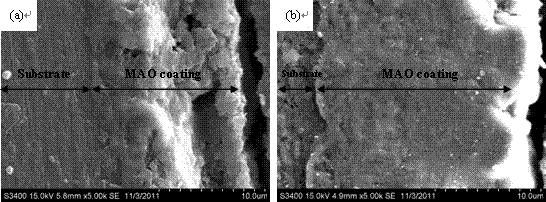

Embodiment 1

[0037] The as-cast Mg-9.05wt.%Al-0.65wt.%Zn alloy was processed into a columnar specimen of 19.5mm×19.5mm×40mm by wire cutting. The as-cast microstructure was mainly composed of α(Mg) matrix and interdendritic structures. Network distribution of Mg 17 Al 12 (β) phase composition (see figure 1 (a)). The β phase exists in two forms, one is the coarse bulk β phase, and the other is the fine lamellar β phase in the (α+β) eutectic structure. The surface of the cut specimen was pretreated, and then placed in the mold and heated to 250 °C for 10 min with the furnace, and then pressure was applied for 16 consecutive passes of ECAP extrusion, and the specimen was rotated 180° between adjacent extrusion passes. (i.e. the traditional C path) to improve the uniformity of the extrusion structure, the alloy structure is significantly refined after processing (see figure 1 (b)). The yield strength and tensile strength of Mg-9.05wt.%Al-0.65wt.%Zn alloy are greatly improved after ECAP pro...

Embodiment 2

[0039] The as-cast Mg-9.05wt.%Al-0.65wt.%Zn alloy was processed into a columnar specimen of 19.5mm×19.5mm×40mm by wire cutting. The as-cast microstructure was mainly composed of α(Mg) matrix and interdendritic structures. Network distribution of Mg 17 Al 12 (β) phase composition (see figure 1 ). The β phase exists in two forms, one is the coarse bulk β phase, and the other is the fine lamellar β phase in the (α+β) eutectic structure. The surface of the cut specimen was pretreated, and then placed in the mold and heated to 250 °C for 10 minutes, and then pressure was applied for 12 consecutive passes of ECAP extrusion, and the specimen was rotated 180° between adjacent extrusion passes. (i.e. the traditional C path) to improve the uniformity of the extrusion structure, the alloy structure is significantly refined after processing (see Figure 8 ). After the Mg-9.05wt.%Al-0.65wt.%Zn alloy was processed by ECAP for 12 passes, the yield strength was 133.43MPa and the tensile ...

Embodiment 3

[0041] The as-cast Mg-9.05wt.%Al-0.65wt.%Zn alloy was processed into a columnar specimen of 19.5mm×19.5mm×40mm by wire cutting. The as-cast microstructure was mainly composed of α(Mg) matrix and interdendritic structures. Network distribution of Mg 17 Al 12 (β) phase composition (see figure 1 ). The β phase exists in two forms, one is the coarse bulk β phase, and the other is the fine lamellar β phase in the (α+β) eutectic structure. The surface of the cut specimen was pretreated, and then placed in the mold and heated to 250 °C for 10 min with the furnace, and then pressure was applied for 8 consecutive ECAP extrusions, and the specimen was rotated 180° between adjacent extrusion passes. (i.e. the traditional C path) to improve the uniformity of the extrusion structure, the alloy structure is elongated after processing, and the grains are significantly refined (see Figure 13 ). After 8 passes of ECAP processing, the Mg-9.05wt.%Al-0.65wt.%Zn alloy has a yield strength of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com