Method for active control over electric arc additive manufacturing forming quality

An additive manufacturing and active control technology, applied in the field of additive manufacturing, can solve the problems of low forming efficiency, increased production cost, inability to realize active control of the structure of the formed parts with dimensional deviation, etc., and achieve the effect of an efficient method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to express the manufacturing advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with specific examples.

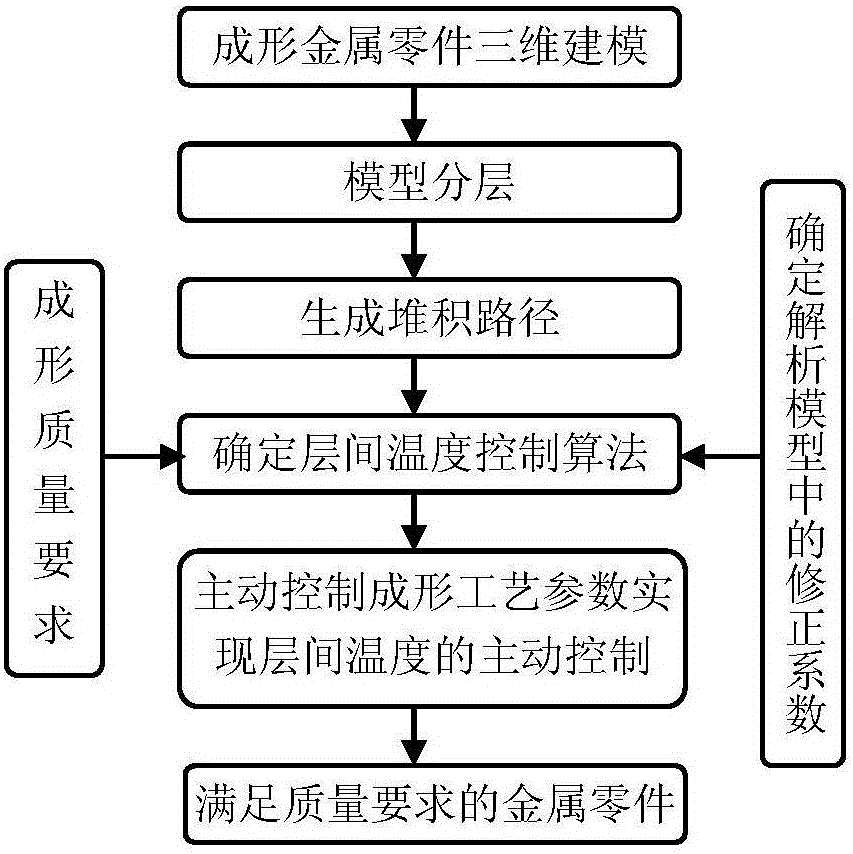

[0014] The present invention uses CAD software to establish a three-dimensional model of a formed part. First, according to the shape structure and size of the formed part, the model is layered and sliced; secondly, the forming path is planned according to the size and shape characteristics of each layered slice, and the production The NC codes required for the forming of each layer, use the produced NC codes to control the movement of the CNC machine tool to realize the accumulation and forming of each layer.

[0015] According to the quality requirements of formed metal parts, determine the interlayer temperature distribution characteristics during the forming process, and then set the corresponding interlayer temperature control algorithm based on the thermodynamic criterion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com