Method for preparing activated carbon with sludge as raw material

A technology for preparing activated carbon and activated carbon, which is applied in the field of activated carbon, can solve the problems of unstable properties, perishability, environmental pollution, etc., and achieve the effect of good adsorption effect and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

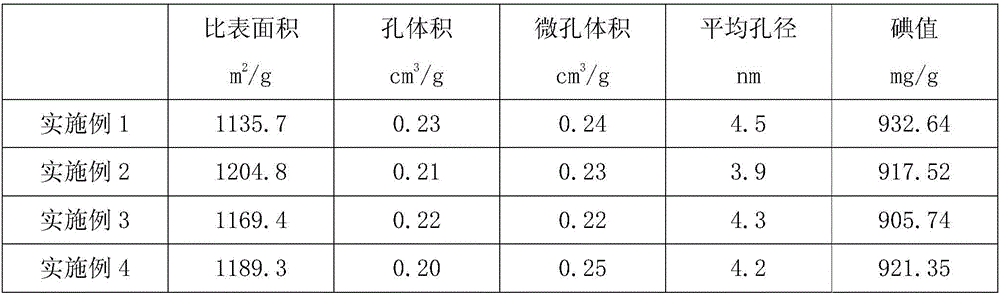

Examples

Embodiment 1

[0017] A method for preparing activated carbon from sludge, comprising the following steps:

[0018] Step 1, taking sludge, centrifugal dehydration, drying, and grinding to obtain dry sludge;

[0019] Step 2, in parts by weight, mix 10 parts of dry sludge with 0.2 parts of zinc chloride, 0.5 parts of tartaric acid, 0.1 parts of tetrabutyl titanate and 3 parts of isopropanol, stand at 30°C for 30 hours, and dry to obtain Activated sludge;

[0020] Step 3, in parts by weight, mix 10 parts of activated sludge with 0.5 parts of citric acid, 0.3 parts of mannitol, and 0.1 parts of sodium alginate, and heat up to 600 ° C for 5 hours under nitrogen to carbonize to obtain crude activated carbon;

[0021] In step 4, the obtained activated carbon crude product is acid-washed, washed with water, and dried to obtain activated carbon.

[0022] Among them, the particle size of the dried sludge in step 1 is 1-2mm, the drying temperature in step 2 is 100°C, the heating rate in step 3 is 15°...

Embodiment 2

[0024] A method for preparing activated carbon from sludge, comprising the following steps:

[0025] Step 1, taking sludge, centrifugal dehydration, drying, and grinding to obtain dry sludge;

[0026] Step 2, in parts by weight, mix 10 parts of dry sludge with 0.4 parts of zinc chloride, 1.2 parts of tartaric acid, 0.3 parts of tetrabutyl titanate and 5 parts of isopropanol, stand at 40°C for 25 hours, and dry to obtain Activated sludge;

[0027] Step 3, in parts by weight, mix 10 parts of activated sludge with 0.8 parts of citric acid, 0.5 parts of mannitol, and 0.2 parts of sodium alginate, and heat up to 650 ° C for 3 hours under nitrogen to carbonize to obtain crude activated carbon;

[0028] In step 4, the obtained activated carbon crude product is acid-washed, washed with water, and dried to obtain activated carbon.

[0029] Among them, the particle size of the dried sludge in step 1 is 1-2mm, the drying temperature in step 2 is 100°C, the heating rate in step 3 is 15°...

Embodiment 3

[0031] A method for preparing activated carbon from sludge, comprising the following steps:

[0032] Step 1, taking sludge, centrifugal dehydration, drying, and grinding to obtain dry sludge;

[0033] Step 2, in parts by weight, mix 10 parts of dry sludge with 0.7 parts of zinc chloride, 1.7 parts of tartaric acid, 0.3 parts of tetrabutyl titanate and 6 parts of isopropanol, stand at 40°C for 30 hours, and dry to obtain Activated sludge;

[0034] Step 3, in parts by weight, mix 10 parts of activated sludge with 1.3 parts of citric acid, 0.5 parts of mannitol, and 0.4 parts of sodium alginate, and heat up to 600 ° C for 5 hours under nitrogen to carbonize to obtain crude activated carbon;

[0035] In step 4, the obtained activated carbon crude product is acid-washed, washed with water, and dried to obtain activated carbon.

[0036] Among them, the particle size of the dried sludge in step 1 is 1-2mm, the drying temperature in step 2 is 100°C, the heating rate in step 3 is 15°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com