An artificial rapid percolation system for enhanced denitrification

An artificial rapid percolation and denitrification technology, which is applied in chemical instruments and methods, aerobic and anaerobic process treatment, granular microbial carrier treatment, etc., can solve the problem of low removal efficiency of total nitrogen, and achieve simple structure and high treatment efficiency. Good effect, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

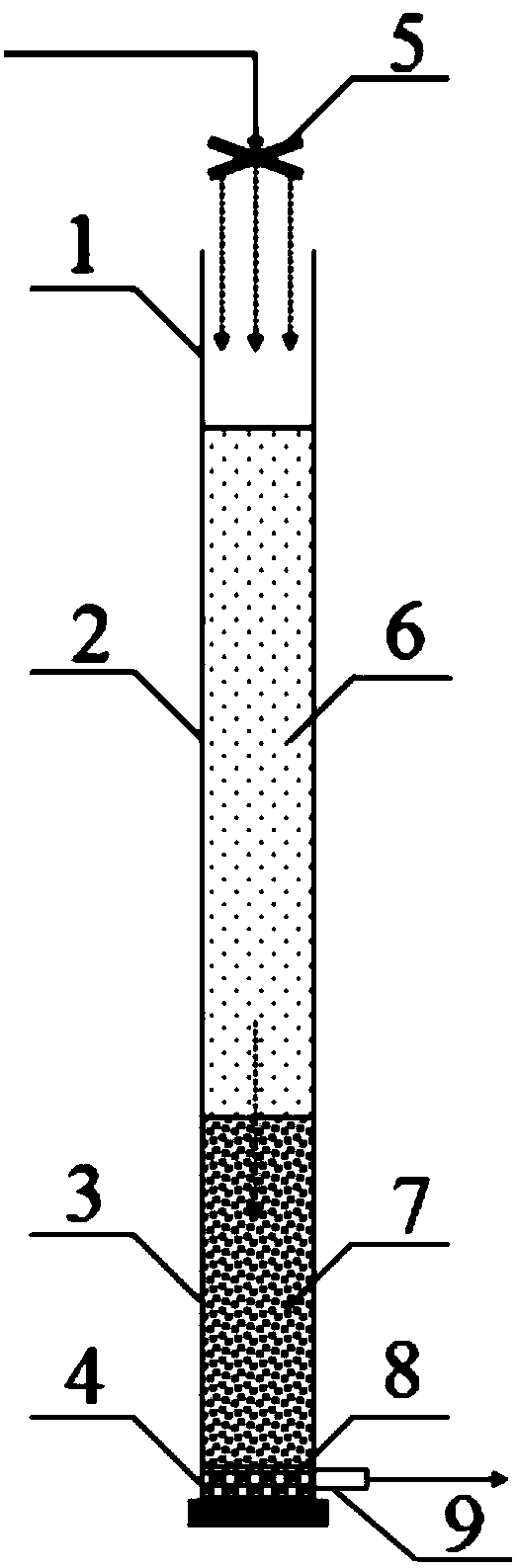

Method used

Image

Examples

experiment example 1

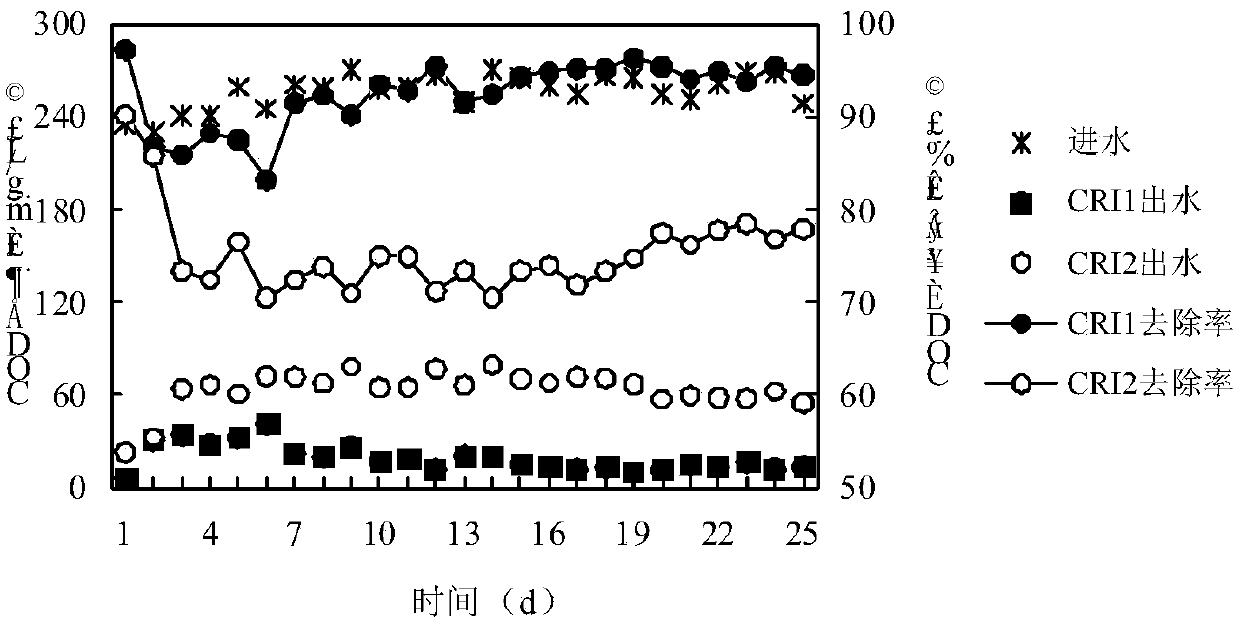

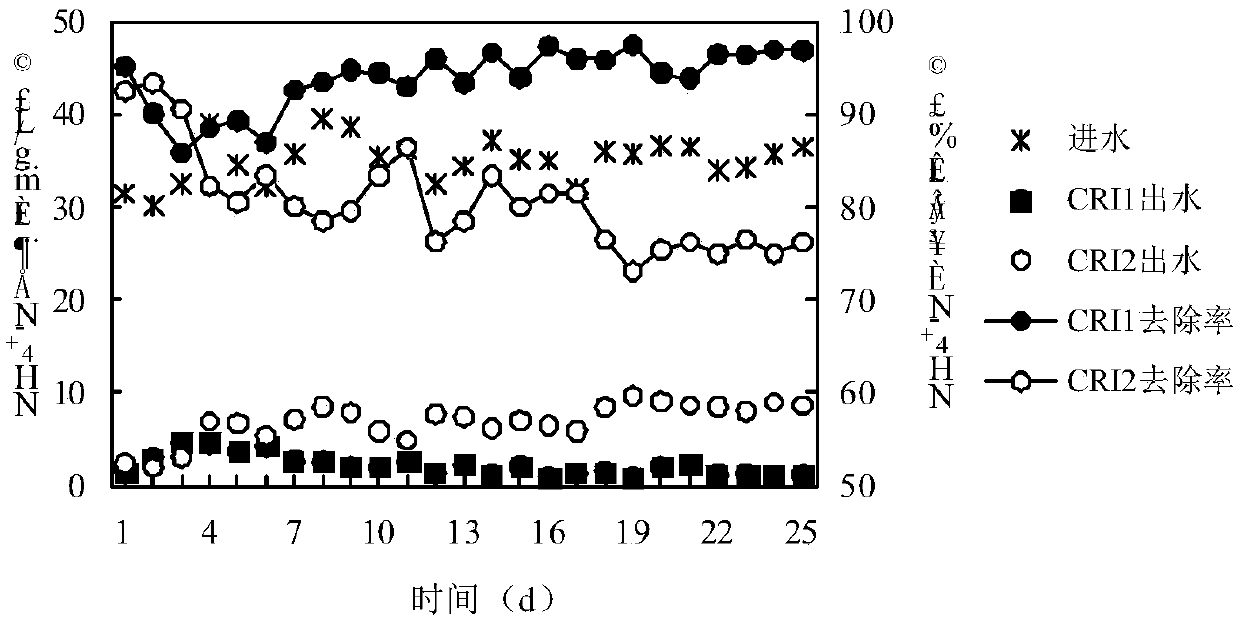

[0046] Taking the domestic sewage of a community in Xipu Town, Pi County as the treatment object, the sewage water quality is as follows: COD, NH 4 + -N, TN, TP, SS concentrations are 230.1~270.5mg / L, 30.2~39.6mg / L, 37.9~46.5mg / L, 3.1~4.2mg / L, 150~400mg / L, pH is 6.8~7.6 . CRI1 and CRI2 use the same water quality to feed water at the same time to eliminate the impact of water quality fluctuations on the system operation effect. Simple pretreatment is performed on domestic sewage before water intake to remove large suspended solids and sediments.

[0047] The operation mode is as follows: CRI1 water intake adopts the alternate operation mode of flooding / drying / staying, the hydraulic load is 0.75m / d, the hydraulic load cycle is 8h, of which the aerobic nitrification stage is 3h, the wet-dry ratio is 1:3, and it enters the anoxic compound After the denitrification section, stay for 5 hours, and then discharge from the water outlet; CRI2 water intake adopts the method of flooding...

experiment example 2

[0058] Taking a eutrophic lake in Xipu Town, Pi County as the treatment object, the sewage water quality is as follows: COD, NH 4 + -N, TN, TP, SS concentrations are 20.5~35.8mg / L, 1.8~4.8mg / L, 3.2~8.6mg / L, 0.37~0.66mg / L, 45~115mg / L, pH is 7.2~7.8 . CRI1 and CRI2 use the same water quality to feed water at the same time, so as to eliminate the influence of water quality fluctuations on the system operation effect, and perform simple pretreatment on eutrophic lake water before water intake to remove large suspended solids and sediments.

[0059] The operation mode is as follows: CRI3 water intake adopts the method of flooding / drying / staying alternately, the hydraulic load is 1.5m / d, the hydraulic load cycle is 4h, of which the aerobic nitrification stage is 2h, the wet-dry ratio is 1:4, and it enters the anoxic compound After the denitrification section, stay for 2 hours, and then discharge from the water outlet; CRI4 water intake adopts the alternate flooding / falling-drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com