Multi-layer composite runner brick and production method thereof

A multi-layer composite and flow steel brick technology, applied in the field of refractory materials, can solve the problems of poor erosion resistance, easy cracking, poor thermal shock performance, etc., to achieve good resistance to molten steel erosion, resistance to molten steel erosion and erosion, Effect of thermal shock stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

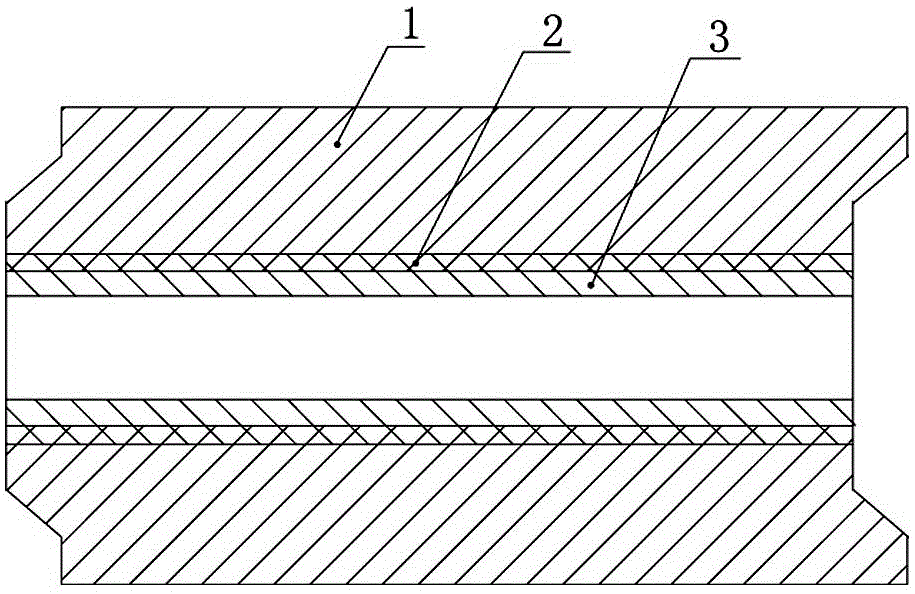

Image

Examples

Embodiment Construction

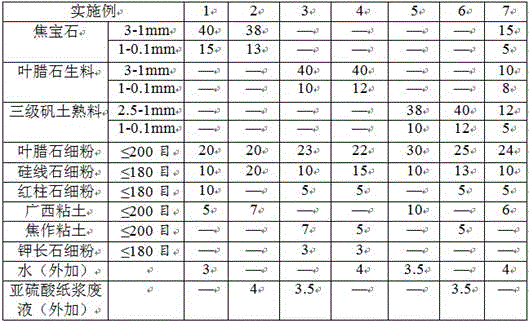

[0031] Below by embodiment 1~7, the present invention is described in more detail.

[0032] Table 1 and Table 2 are respectively the raw material proportions of the brick matrix and the raw material proportions of the working layer slurry in Examples 1 to 7.

[0033] Table 1 Ratio of brick matrix raw materials in Examples 1 to 7 (by weight percentage)

[0034]

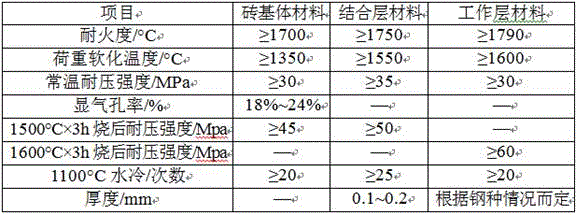

[0035] Table 2 Raw material ratio of working layer slurry in Examples 1-7 (by weight percentage)

[0036] .

[0037]The production method of multi-layer composite flow steel brick of the present invention comprises following specific steps (the preparation method of embodiment 1~7 is identical):

[0038] The first step, the preparation of adobe

[0039] Accurately weigh each raw material according to the ratio in Table 1, add it to the mixer and dry mix it for 3-5 minutes, then add the binder and mix it for 5-8 minutes to form a uniform mud; put the mud in the brick press Internally (pressure 80~120MPa) presse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com