Graphene modified glue solution and preparation method and application thereof

A graphene modification, graphene technology, applied in adhesives, textiles and papermaking, adhesive types, etc., can solve the problems of short sustainability, difficult industrialization implementation, deterioration of production environment, etc., to improve adhesion performance, preparation The method is simple and reliable, and the effect of improving the thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

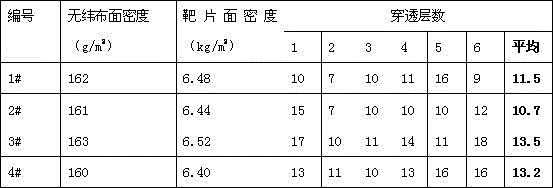

Examples

Embodiment 1

[0019] Prepare modified glue

[0020] 400g of commercially available AT-06 water-based polyurethane adhesive with a solid content of 45% was used as the base material to prepare the modified glue. Firstly, 0.8 g of graphene powder and 8 g of polyvinylpyrrolidone were put into 160 g of deionized water, stirred at high speed for 60 min, and the stirring speed was 1000 rpm. Put the water-based polyurethane adhesive base material on the stirring device for slow stirring, the stirring speed is 40rpm. Gradually add the dispersed graphene aqueous dispersion into the adhesive base material being stirred, and continue stirring for 60 minutes after the addition is complete. Then put the uniformly stirred mixed solution together with the container into a 3kw ultrasonic generator, ultrasonically vibrate for 60 minutes, take it out and let it stand for 48 hours. Finally, the sediment at the bottom of the container is filtered off, and the evenly mixed emulsion in the upper part is retain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com