Compounding type natural gas hydrate inhibitor

A technology of hydrate inhibitor and natural gas, which is applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of inability to be applied on a large scale and insufficient suppression ability, and achieve low cost, prolong generation time, and improve suppression performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

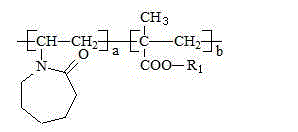

Embodiment 1

[0035] Based on the quality of water in the system, a composite hydrate inhibitor containing poly(vinyl caprolactam-benzyl methacrylate) copolymer with a mass concentration of 1% and methanol with a mass concentration of 5% was prepared, and then a certain amount of THF was added to make it The concentration is 19wt%, and the performance evaluation is carried out by THF method. Under normal pressure, the reaction temperature was maintained at 0°C, the stirring speed was kept consistent in each experiment, and the inhibition time was greater than 75h.

Embodiment 2

[0037] Based on the quality of water in the system, a compound hydrate inhibitor containing 3% poly(vinyl caprolactam-benzyl methacrylate) copolymer mass concentration and 5% ethylene glycol butyl ether mass concentration was prepared, and then a certain amount of THF, so that the concentration of 19wt%, using the THF method for performance evaluation. Under normal pressure, the reaction temperature was maintained at 0°C, the stirring speed was kept consistent in each experiment, and the inhibition time was longer than 65h.

Embodiment 3

[0039] Based on the quality of water in the system, a composite hydrate inhibitor containing 3% poly(vinyl caprolactam-benzyl methacrylate) copolymer mass concentration and 5% ethylene glycol mass concentration was prepared, and then a certain amount of THF was added, The concentration was adjusted to 19 wt%, and performance evaluation was performed by the THF method. Under normal pressure, the reaction temperature was maintained at 0°C, the stirring speed was kept consistent in each experiment, and the inhibition time was longer than 55h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com