A preparation process of external oxidation dispersion strengthened copper alloy

A dispersion-strengthened copper and preparation process technology is applied in the field of preparation of external oxidation dispersion-strengthened copper alloys. The equipment is simple and reliable, and the effect of market-oriented production is realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

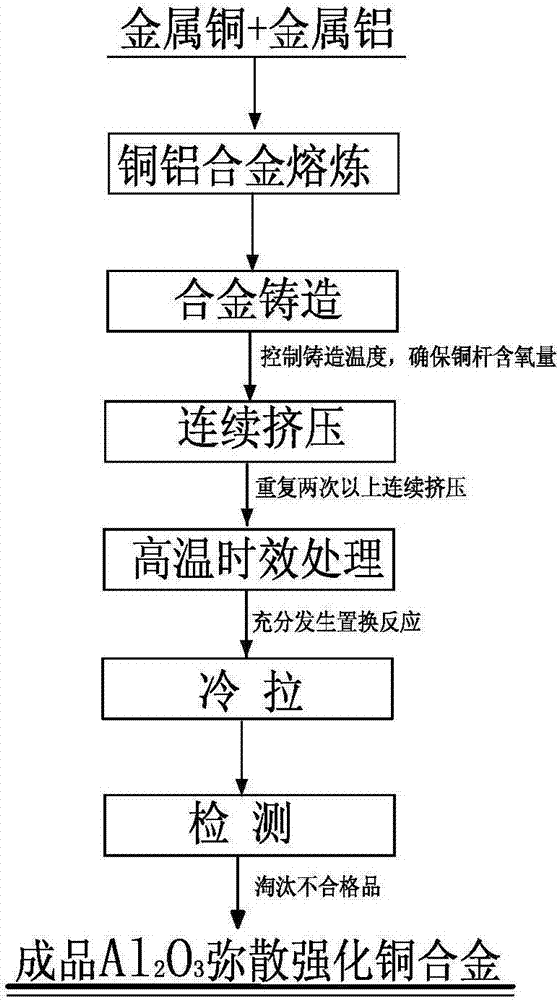

[0034] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation of the preparation process for a kind of external oxidation dispersion strengthened copper alloy proposed according to the present invention Mode, structure, feature and effect thereof are as follows in detail.

[0035] Process method of the present invention is specifically as follows:

[0036] (1) Copper and aluminum are smelted according to different alloy grades, the Cu content is controlled at 99.93-99.3wt%, the Al content is 0.07-0.7wt%, the temperature of the melting furnace is controlled at 1250-1300°C, and the selection of furnace functions must ensure The alloy components are mixed and stirred evenly;

[0037](2) Carry out uplifting or horizontal or belt-type continuous casting of the smelted copper and aluminum a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com