Treatment method for scale on surface of vanadium production equipment

A technology of production equipment and treatment method, which is applied in the field of metallurgy, can solve the problems of unsatisfactory treatment effect and low efficiency of scaling treatment on the surface of vanadium production equipment, and achieve the effects of increasing vanadium yield, protecting the environment, and ensuring smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

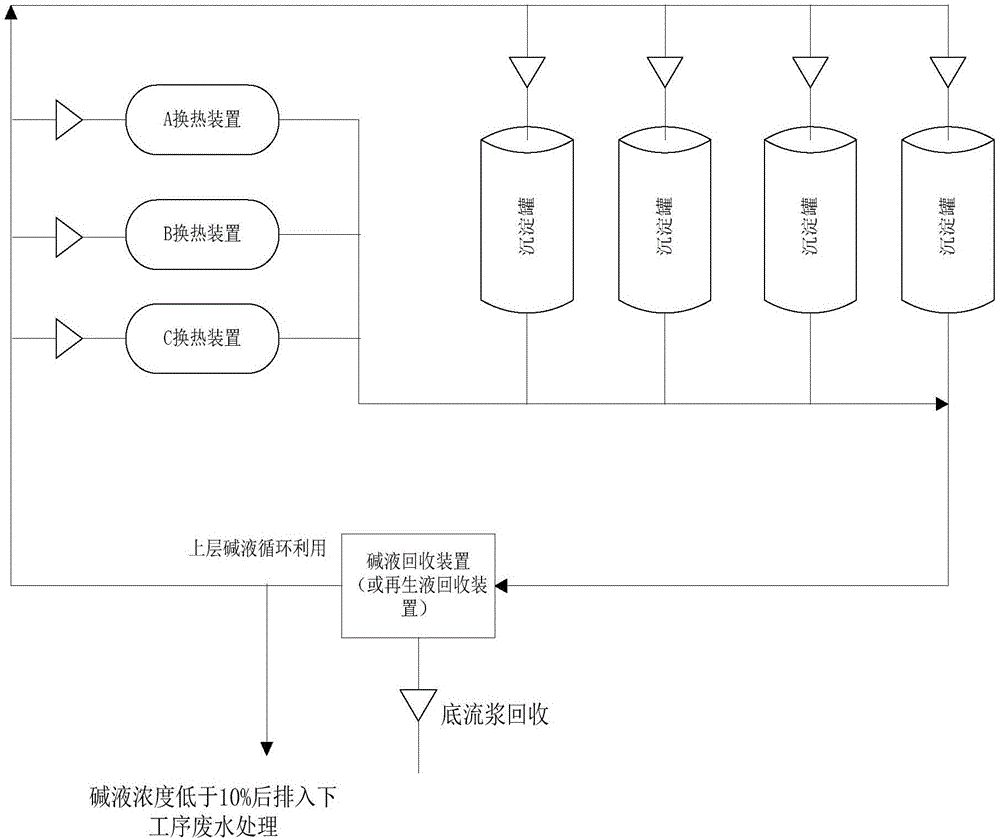

Method used

Image

Examples

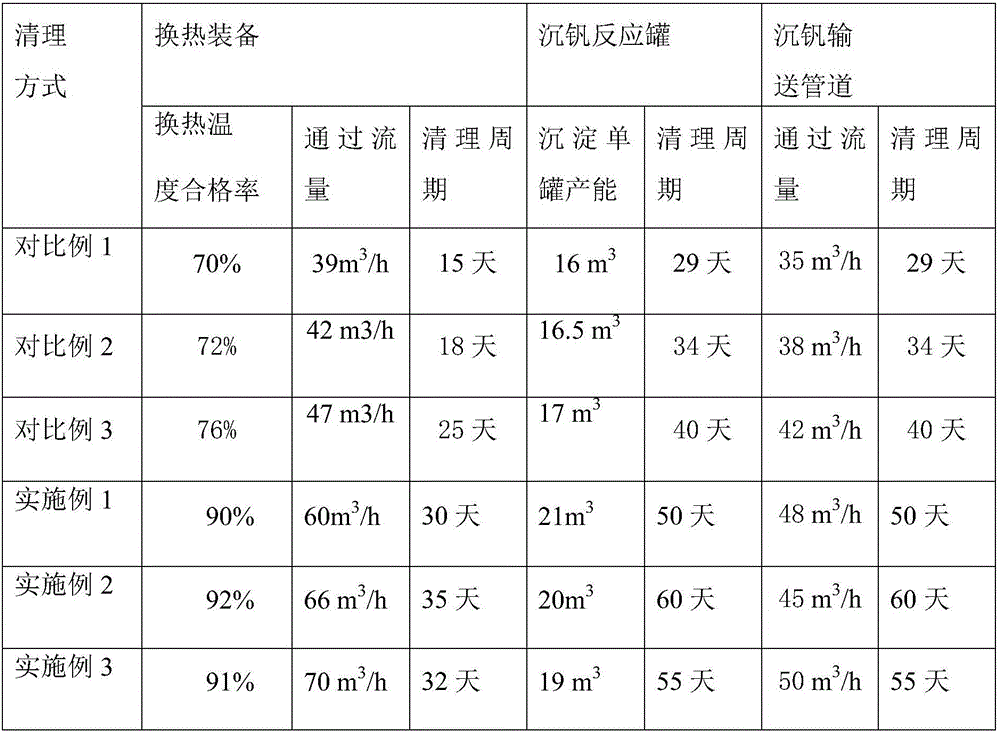

Embodiment 1

[0042] Measure the fouling layer thickness 200mm of the vanadium transport pipe with a vernier caliper; according to the formula descaling agent consumption: (scaling layer thickness*equipment internal surface area)=250kg / m Calculate the descaling agent consumption 2000kg; Prepare NaOH mass concentration as 51% Descaling agent 8000L; inject the prepared descaling agent into the vanadium precipitation equipment, heat it to 70°C, and keep it warm for 10 hours; discharge and recycle the descaling sewage in the vanadium precipitation equipment; clean the inner wall of the equipment with clean water, and test the pH of the cleaning water to 7.1 , Stop cleaning when the turbidity is 200-300; part of the cleaning water is recovered for the preparation of descaling agent, and the cleaning effect is shown in Table 1.

Embodiment 2

[0044] Use a vernier caliper to measure the thickness of the scaling layer of the vanadium-precipitating heat exchange equipment to 100mm; according to the formula descaling agent dosage: (thickness of the scaling layer*equipment inner surface area)=200kg / m3 calculate the amount of descaling agent 800kg; prepare KOH mass concentration of 42% 4000L of descaling agent; inject the prepared descaling agent into the vanadium precipitation equipment, heat it to 100°C, and keep it warm for 20h; discharge and recycle the descaling sewage in the vanadium precipitation equipment; clean the inner wall of the equipment with clean water, and test the pH of the cleaning water 7.0, stop cleaning when the turbidity is 200-300; part of the cleaning water is recovered for the preparation of descaling agent, and the cleaning effect is shown in Table 1.

Embodiment 3

[0046] Measure the fouling layer thickness 150mm of vanadium precipitation reaction tank with vernier caliper; According to the amount of formula descaling agent: (thickness of fouling layer*equipment internal surface area)=230kg / m Calculate the amount of descaling agent 1400kg; Prepare Na 2 CO 3 6000L of descaling agent with a mass concentration of 42%; inject the prepared descaling agent into the vanadium precipitation equipment, heat it to 85°C, and keep it warm for 15 hours; discharge and recycle the descaling sewage in the vanadium precipitation equipment; wash the inner wall of the equipment with clean water, Check the pH of the cleaning water to be 7.0, and stop cleaning when the turbidity is 200-300; part of the cleaning water is recovered for the preparation of descaling agent, and the cleaning effect is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com