Manufacturing method of aluminum alloy sound insulation door

An aluminum alloy, sound insulation door technology, applied in the direction of sound insulation doors/windows, chemical instruments and methods, door leaves, etc., can solve the problems of poor sound insulation effect of metal doors, improve strength and fire protection effect, excellent sound insulation effect, heat resistance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment 1

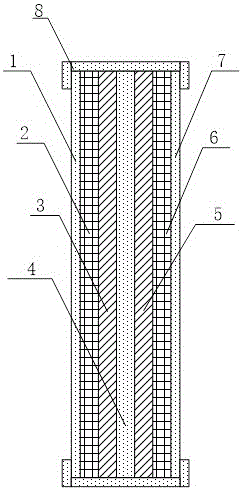

[0033] A method for preparing an aluminum alloy soundproof door, comprising a door frame and a door leaf, the door leaf including an inner door panel (1) and an outer door panel (7), and a frame (8) connecting the inner door panel and the outer door panel, arranged sequentially from the inside to the outside There are inner door panels (1), first fire protection layer (2), first sound insulation layer (3), core board layer (4), second sound insulation layer (5), second fire protection layer (6), outer door panels (7 ), the inner door panel (1) and the outer door panel (7) are all made of aluminum alloy, first the first fireproof layer (2), the first sound insulation layer (3), the core layer (4 ), the second sound insulation layer (5), the second fire protection layer (6), the outer door panel (7), and then use the frame to fix the inner door panel and the outer door panel. Its preparation method is:

[0034] The inner door panel, outer door panel and frame are all made of al...

Embodiment 2

[0053] A method for preparing an aluminum alloy soundproof door, comprising a door frame and a door leaf, the door leaf including an inner door panel (1) and an outer door panel (7), and a frame (8) connecting the inner door panel and the outer door panel, arranged sequentially from the inside to the outside There are inner door panels (1), first fire protection layer (2), first sound insulation layer (3), core board layer (4), second sound insulation layer (5), second fire protection layer (6), outer door panels (7 ), first place the first fireproof layer (2), the first soundproof layer (3), the core layer (4), the second soundproof layer (5), the second fireproof layer (6), the outer doorboard (7), and then use the frame to fix the inner and outer door panels.

[0054] The inner door panel, outer door panel and frame are all made of aluminum alloy die-casting plate, and the aluminum alloy die-casting plate is prepared from the following raw materials in weight percentage: 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com