An energy-saving organic waste gas treatment system

A technology of organic waste gas and treatment system, applied in the directions of gas treatment, combustion type, separation method, etc., can solve the problems of poor treatment effect, damage to staff and residents, large energy consumption, etc., to achieve convenient transformation, obvious energy saving effect, convenient effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

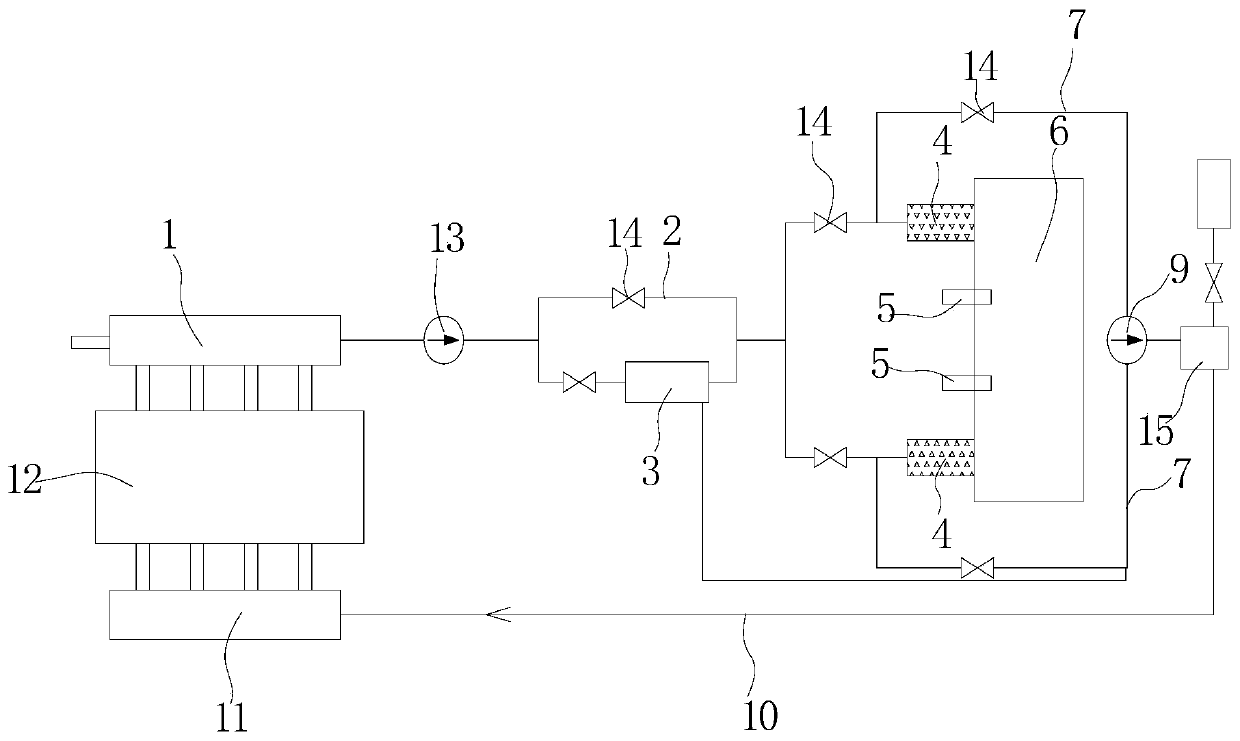

[0018] An energy-saving organic waste gas treatment system, such as figure 1 As shown, it can be used for drying kilns, curing furnaces in spraying workshops, and other organic waste gas discharge systems, which include a waste gas discharge pipe 1 connected to the kiln exhaust port and a combustion and decomposition furnace. The waste gas discharge pipe 1 discharges The exhaust gas is introduced into the combustion decomposition furnace through the exhaust pipe for high-temperature combustion treatment, and the organic matter (especially volatile organic gas) in the exhaust gas is burned and decomposed, and then discharged, which can greatly reduce air pollution. The combustion decomposition furnace includes a combustion chamber 6 , a burner 5 and at least two regenerative heat exchangers 4 . The burner 5 is installed in the combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com