A kind of treatment technology of phenol cyanide sewage

A treatment process and sewage technology, applied in the field of phenol cyanide sewage treatment process, can solve the problems of cumbersome operation and management, difficult degradation of organic matter, environmental pollution, etc., and achieve the effect of simple operation and management, eliminating influence and reducing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is further described.

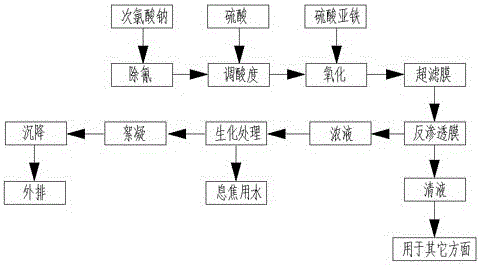

[0020] see figure 1 , a treatment process for phenol cyanide sewage, its processing steps are:

[0021] The first step: first add sodium hypochlorite to phenol cyanide sewage, sodium hypochlorite is an effective method to remove cyanide ions and their compounds in sewage, under the condition of proper pH control, add NaClO solution to wastewater to make CN - is oxidized to CO 2 and N 2 , the response is as follows:

[0022] CN - +ClO - +H 2 O→CNCl+2OH -

[0023] CNCl+2OH - →CNO - +Cl - +H 2 o

[0024] 2CNO - +3ClO - →CO 2 ↑+N 2 ↑+3Cl - +CO 3 2-

[0025] Sodium hypochlorite is a strong oxidizing agent, which can remove most of the organic matter in phenol cyanide wastewater, reducing the difficulty of subsequent biochemical treatment;

[0026] The second step: add ferrous sulfate to the phenolic cyanide wastewater after a period of reaction in the first step, and exce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com