Method and system for controlling indoor quality of automatic assembly lines of medical laboratories

A technology of laboratory automation and quality control methods, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of insufficient deployment of resources, increase of manpower, poor flexibility, etc., to achieve good flexibility, simple and practical system structure, and accurate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

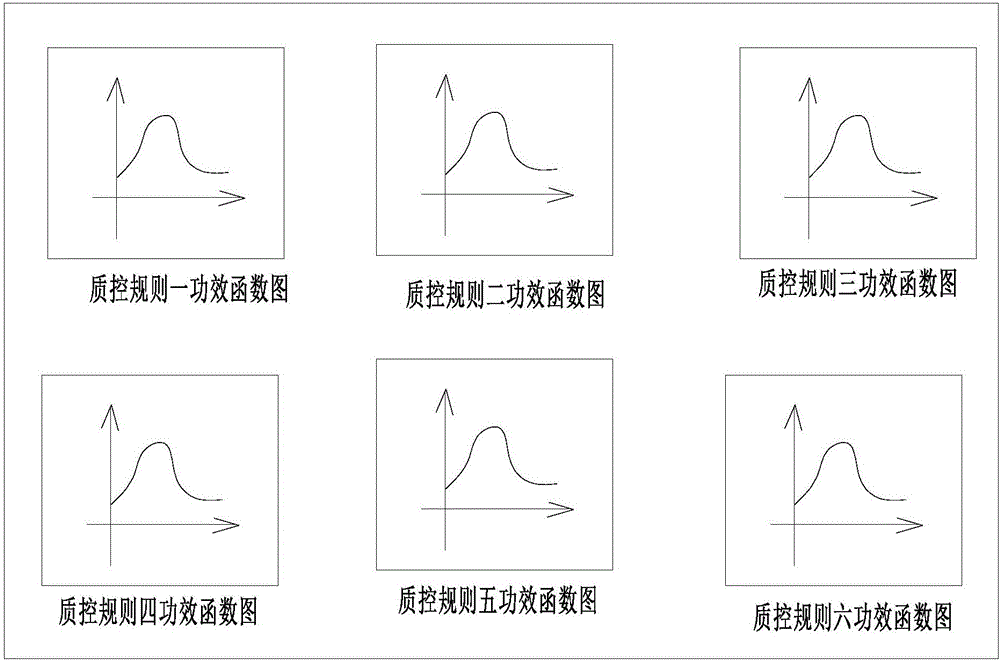

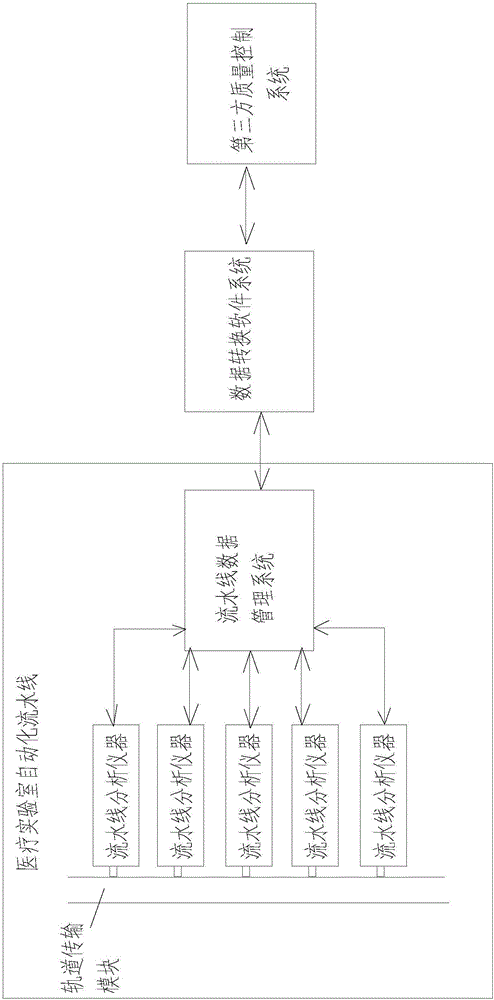

[0032] Such as image 3 , Figure 4 As shown, the indoor quality control method of the medical laboratory automated assembly line of the present invention is characterized by: using a third-party quality management system to set corresponding quality control rules for each test item; data conversion is performed by a data conversion system to convert the test items and The corresponding quality control rules are transmitted to the pipeline data management system of the automated assembly line of the medical laboratory. The pipeline data management system sends the test items and corresponding quality control rules to the corresponding pipeline analysis instrument. The pipeline analysis instrument is equipped with an indoor quality control detection module. The indoor quality control detection module receives the instructions issued by the pipeline data management system and collects the corresponding IQC data according to the quality control rules corresponding to the inspection ...

Embodiment 2

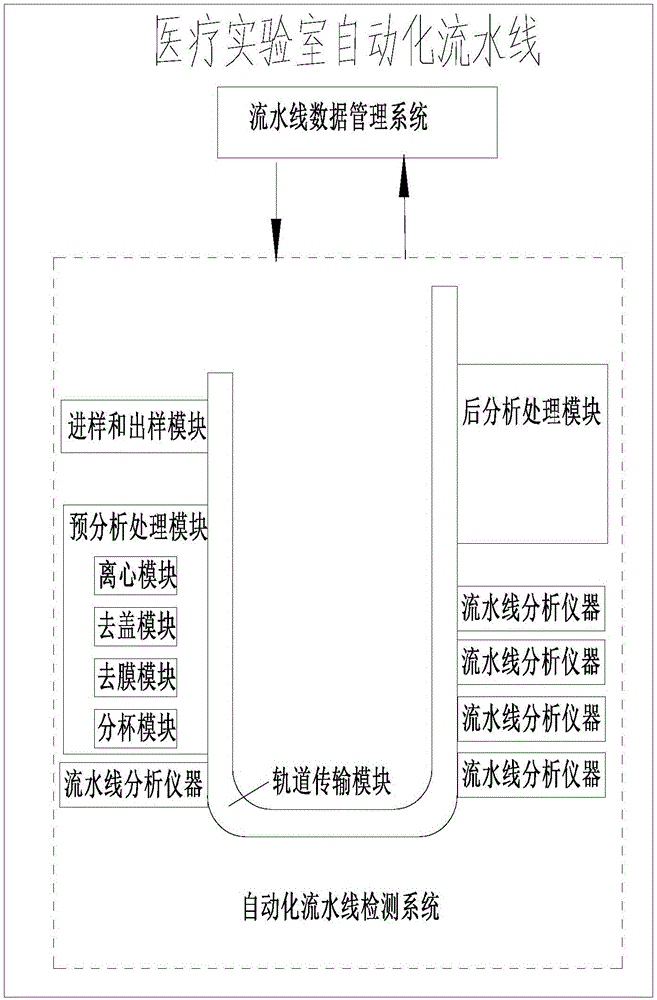

[0051] The medical laboratory automated assembly line indoor quality control system of the present invention includes a medical laboratory automated assembly line, the medical laboratory automated assembly line includes an automated assembly line detection system and an assembly line data management system, and the automated assembly line inspection system includes a rail transmission module , Sampling and sampling module, pre-analysis processing module, multiple assembly line analysis instruments and post-analysis processing module, orbital transport module combines sampling and sampling module, pre-analysis processing module, multiple assembly line analysis instruments and post-analysis processing module Connected in turn, the pipeline data management system communicates with multiple pipeline analysis instruments. The pipeline data management system controls the work of the entire automated pipeline detection system. The pipeline analysis instruments are equipped with an indep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com