Wet crushing and separation technique for waste electric wire cable

A wire and cable, wet crushing technology, applied in the direction of circuit, electrical components, electronic waste recycling, etc., can solve the problems of adverse health effects of workers, expensive equipment, etc., to avoid splashing and improve the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

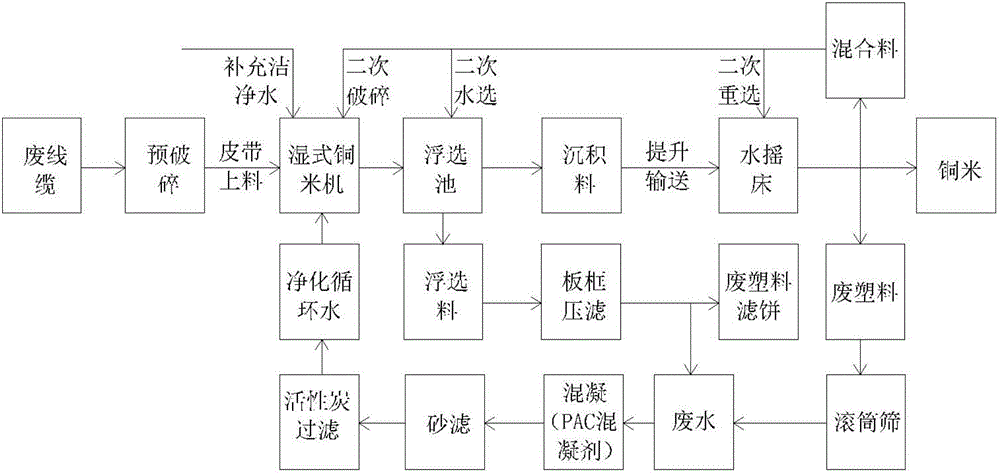

Image

Examples

Embodiment 1

[0021] The main materials of waste wires and cables are copper wires, plastic skins covering the outer layers of copper wires, and other metals mixed into the wires. This embodiment illustrates this process from the perspective of copper recovery.

[0022] The process of recovering copper is as follows:

[0023] First, the waste wires and cables are crushed, using a wet copper rice machine to crush them into copper rice size. At this time, under the crushing action of the copper rice machine, the waste wires and cables are separated from the inner core and insulation skin, forming a mixture of copper rice, plastic and other impurities. The mixed material is sent to the water separation station.

[0024] Then carry out water selection. In the flotation tank, copper rice, plastics and other impurities are rolled in the flotation tank due to running water or agitation. Floating plastics, a small amount of wire fluff and a small amount of fiber float on the water surface of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com