A geared hub motor lubricated with liquid lubricating oil

A lubricating oil and gear technology, applied in the field of geared hub motors, can solve the problems of lack of power output device and fixing device of the motor, poor targeting of four O-rings, and lack of limit devices for coil windings. Pedal riding function, light weight, good high-speed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

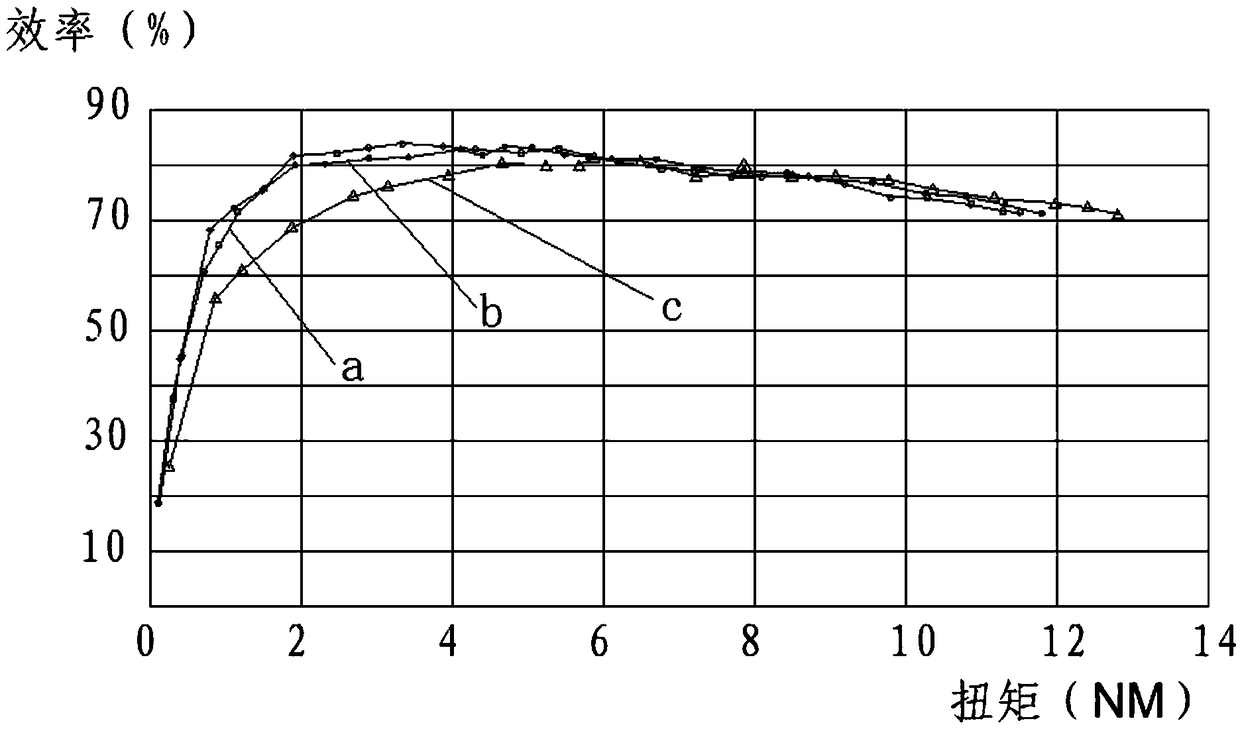

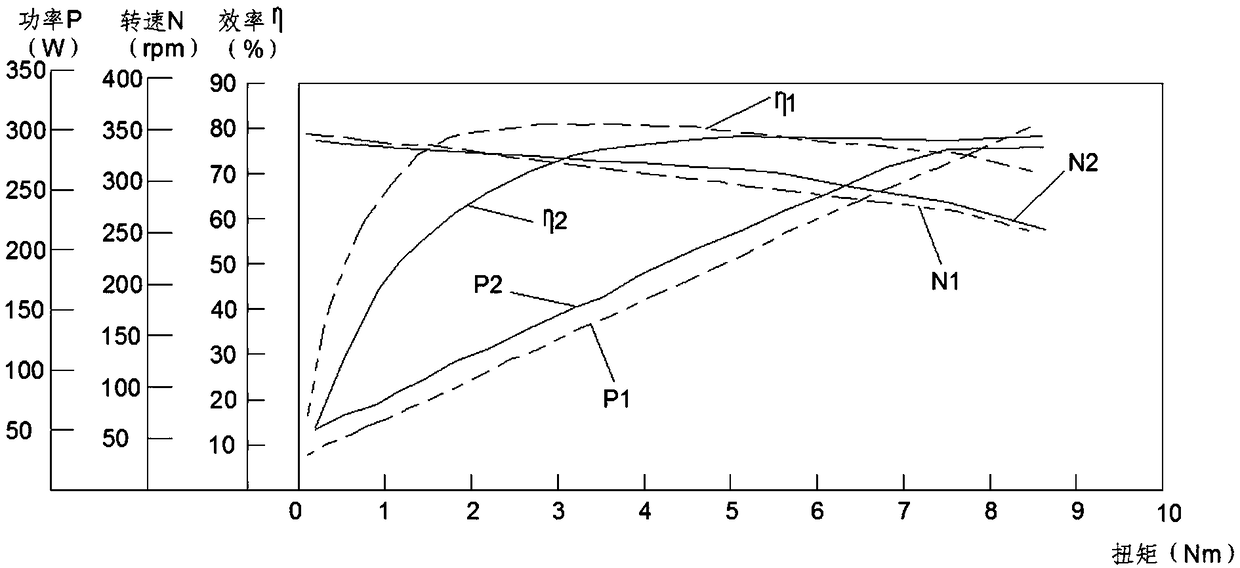

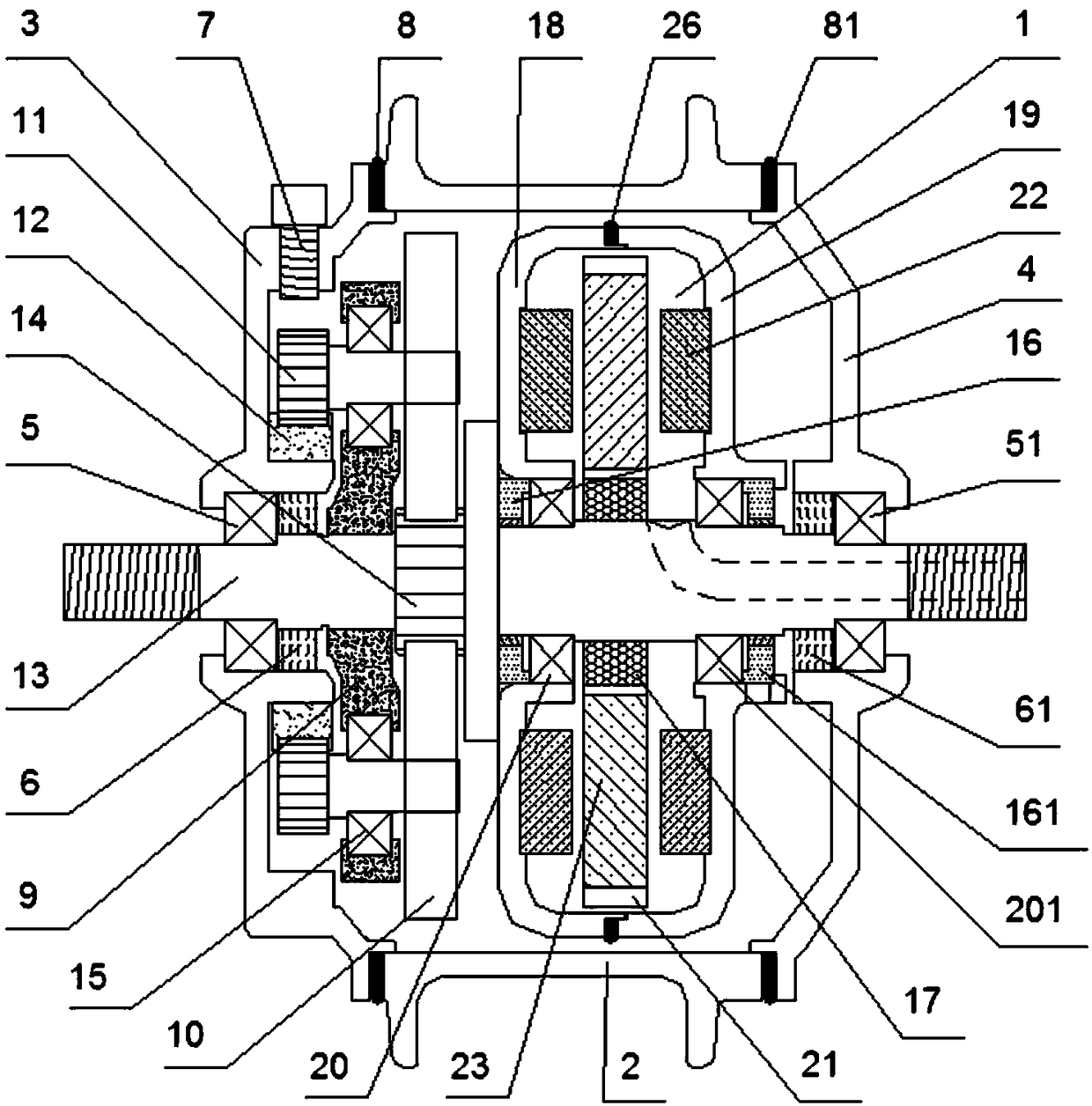

[0043] A geared hub motor lubricated with liquid lubricating oil, the winding is composed of 6 coils 23, the radial diameter of the coils 23 is D=32mm, the height is 10.0mm, the diameter of the copper enameled wire is 0.67mm, the radial length of the triangular hollow is 9.6mm, 8 The average value of inner and outer diameters of 22 units of permanent magnets is 68mm, the axial height is 6mm, and the radial length is 20mm. °, 38° for comparison test; from Figure 9 From the torque efficiency curves shown, the highest efficiencies of the three motors are 83.8%, 83.1%, and 80.6% respectively. After leaving a gap between two adjacent permanent magnet 22 units, the effect on the motor efficiency is not obvious. The influence of the high torque section is smaller, and this result is also consistent with the external magnetic field analysis and experimental results of the energized air-core coil; the change of the gap between the permanent magnets 22 has a greater influence on the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com