Modified halloysite nanotube composite slow release pesticide and preparation method thereof

A technology of halloysite nanotubes and slow-release pesticides, applied in the fields of botanical equipment and methods, chemical instruments and methods, agriculture, etc., can solve the problems of poor slow-release and small drug loading, and achieve low cost and energy saving. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

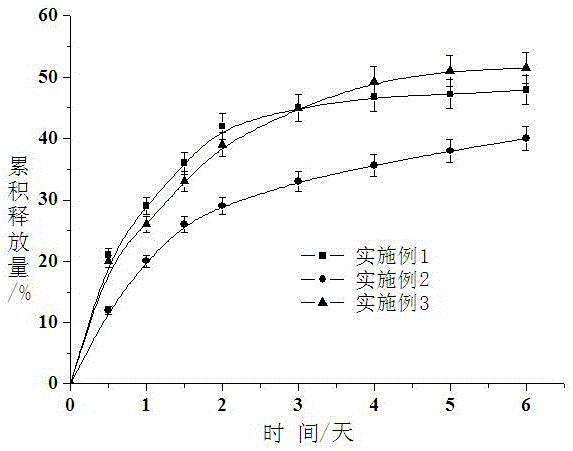

Embodiment 1

[0021] Preparation of halloysite loaded acetochlor sustained-release pesticide

[0022] (1) Weigh 100g of halloysite, slowly add it to 500mL of water under mechanical stirring, continue to add 1000mL of water after stirring for 10 minutes, stir for another 30 minutes and let it stand for 1 hour, discard the lower layer of sand and stones and take the upper layer of slurry, adjust When the pH of the suspension is acidic, heat for 15 minutes to open the pores of the halloysite nanotubes. After flocculent precipitation appears in the suspension, continue to stand for 12 hours, filter with suction, dry, and crush through a 200-mesh sieve to obtain pure Halloysite;

[0023] (2) Mix halloysite and water at a weight ratio of 1:50, fully disperse to form halloysite suspension, and accurately add 1.0% of the quality of the suspension to octadecyltrimethylammonium chloride. Shake at a constant temperature water bath shaker at 65°C at a speed of 150r / min for 3h, so that the exchange rea...

Embodiment 2

[0030] Preparation of Halloysite-loaded Chlorpyrifos Slow-release Pesticide

[0031] Purified halloysite was prepared according to the method described in step (1) of Example 1. Mix halloysite and water at a weight ratio of 1:50, fully disperse halloysite suspension, and accurately add 1.0% cetyltrimethylammonium bromide of the suspension quality, at a temperature of 65 ° C Oscillate on a constant temperature water bath shaker at a speed of 150 r / min for 3 hours, centrifuge, wash, filter with suction, dry, and grind through a 200-mesh sieve to obtain organically modified halloysite. Dissolve chlorpyrifos EC with a mass concentration of 40% in acetone to prepare 50 mL of a solution with a mass concentration of 0.2 g / mL, weigh 0.2 g of organically modified halloysite, add it to the acetone solution, and shake in a constant temperature water bath at 25 °C Shake in the container at a speed of 150r / min for 3h to balance the adsorption of pesticides on halloysite, wash with 50mL di...

Embodiment 3

[0035] Preparation of Dimethoate Sustained Release Pesticide Loaded on Halloysite

[0036] Purified halloysite was prepared according to the method described in step (1) of Example 1. Mix halloysite and water at a weight ratio of 1:50, fully disperse to form halloysite suspension, accurately add 1.0% dioctadecyldimethylammonium bromide of the suspension quality, at a temperature of 65°C Oscillate for 3 hours at a speed of 150 r / min on a constant temperature water bath oscillator, centrifuge, wash, suction filter, dry, and grind through a 200-mesh sieve to obtain organically modified halloysite. Dissolve dimethoate in acetone to prepare 50mL of a solution with a mass concentration of 0.3g / mL, weigh 0.2g of organically modified halloysite, add it to the acetone solution, and place it in a constant temperature water bath shaker at 25°C at 150r Oscillating at a speed of 1 / min for 3 h to balance the adsorption of pesticides on halloysite, washing with 50 mL of distilled water thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com