A combined denitrification system and method for alumina roasting flue gas

A technology of alumina and flue gas, which is applied in the direction of chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of large temperature window influence, ammonia escape, etc., and achieve the effect of reducing usage, reducing impact, and reducing ammonia escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

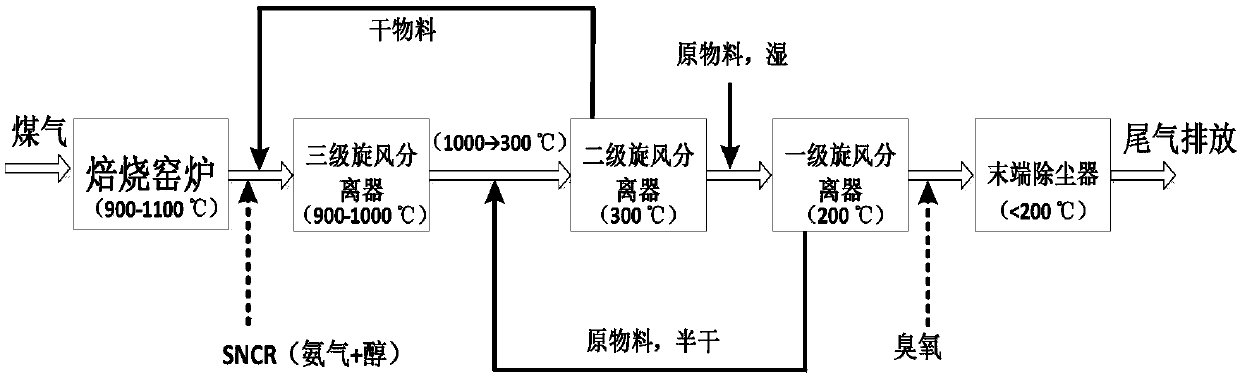

[0029] A combined denitrification system for flue gas from alumina roasting. Along the flue gas flow direction, the combined denitrification system includes a roasting kiln sequentially connected through a flue gas channel, a three-stage cyclone separator, a two-stage cyclone separator, and a first-stage cyclone separator. The cyclone separator and the terminal dust collector, the wet raw material drying inlet is provided between the secondary cyclone separator and the primary cyclone separator, and the wet raw material drying inlet is provided between the secondary cyclone separator and the secondary cyclone separator The semi-dry raw material drying inlet, the dry raw material drying inlet is provided between the roasting kiln and the three-stage cyclone separator, and there is also an ammonia-containing gas inlet between the roasting kiln and the dry raw material drying inlet. The first purified gas inlet for the mixed gas with alcohol organic matter is also provided with th...

Embodiment 1

[0040] According to the combined denitrification system and method in the above embodiments, this example selects an alumina roasting kiln with an annual output of about 500,000 tons for denitrification experimental research. In flue gas, NO x The concentration is 500mg / m 3 , spray 5% ammonia gas at the high temperature of the boiler (about 1000 ° C temperature section), and spray 2% methanol gas after gasification as an additive at the same time; add a concentration of 200mg / m at the low temperature of the boiler feed 3 of ozone. The results show that NO is produced at the flue gas outlet of the alumina roasting kiln x The concentration is reduced to 100mg / m 3 Below, the existence of escaped ammonia can hardly be detected in the exhaust gas at the same time.

Embodiment 2

[0042] According to the combined denitrification system and method in the above embodiments, this embodiment also selects an alumina roasting kiln with an annual output of about 500,000 tons for denitrification experimental research. NO in flue gas x The concentration is 500mg / m 3 , spray 5% ammonia gas at the high temperature of the boiler (about 1000 ° C temperature section), and spray 5% ethanol gas after gasification as an additive at the same time; add a concentration of 250mg / m at the low temperature of the boiler feed 3 of ozone. The results show that NO is produced at the flue gas outlet of the alumina roasting kiln x The concentration is reduced to 100mg / m 3 Below, the existence of escaped ammonia can hardly be detected in the exhaust gas at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com