Production method of five-prevention wood

A production method and five-proof wood technology, applied in the direction of wood drying, wood treatment, wood processing appliances, etc., can solve the problems of no anti-corrosion, waterproof, anti-deformation and cracking, small use range, etc., and achieve extended use time and reliable clamping. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

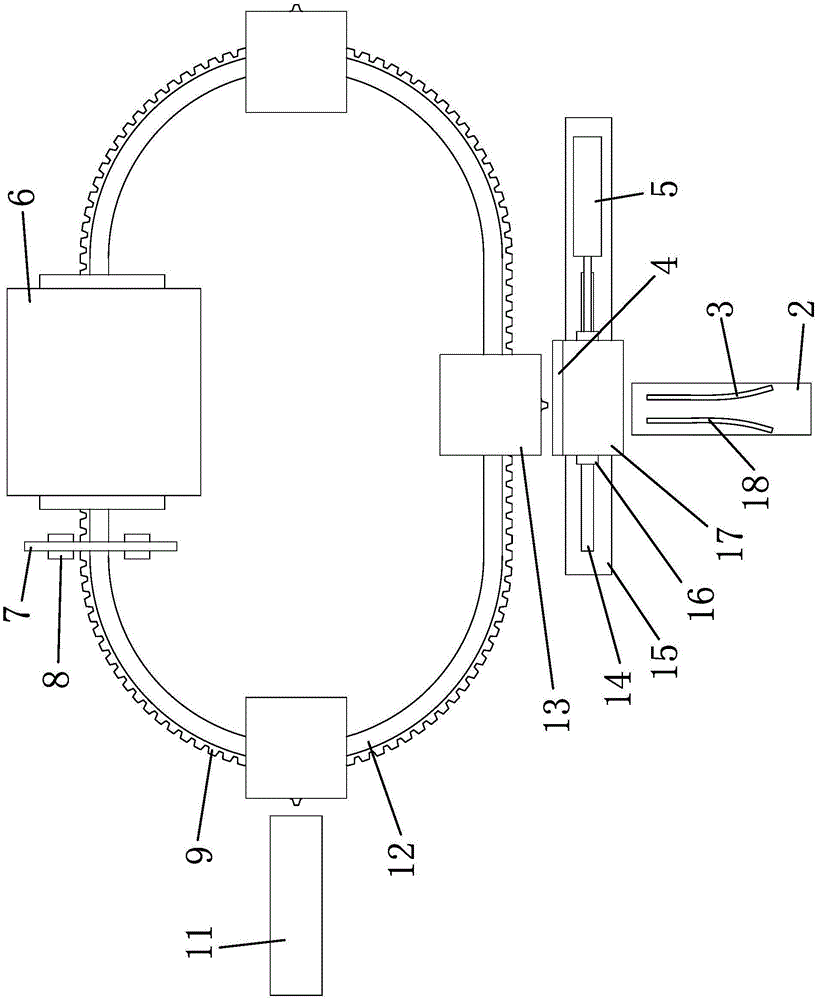

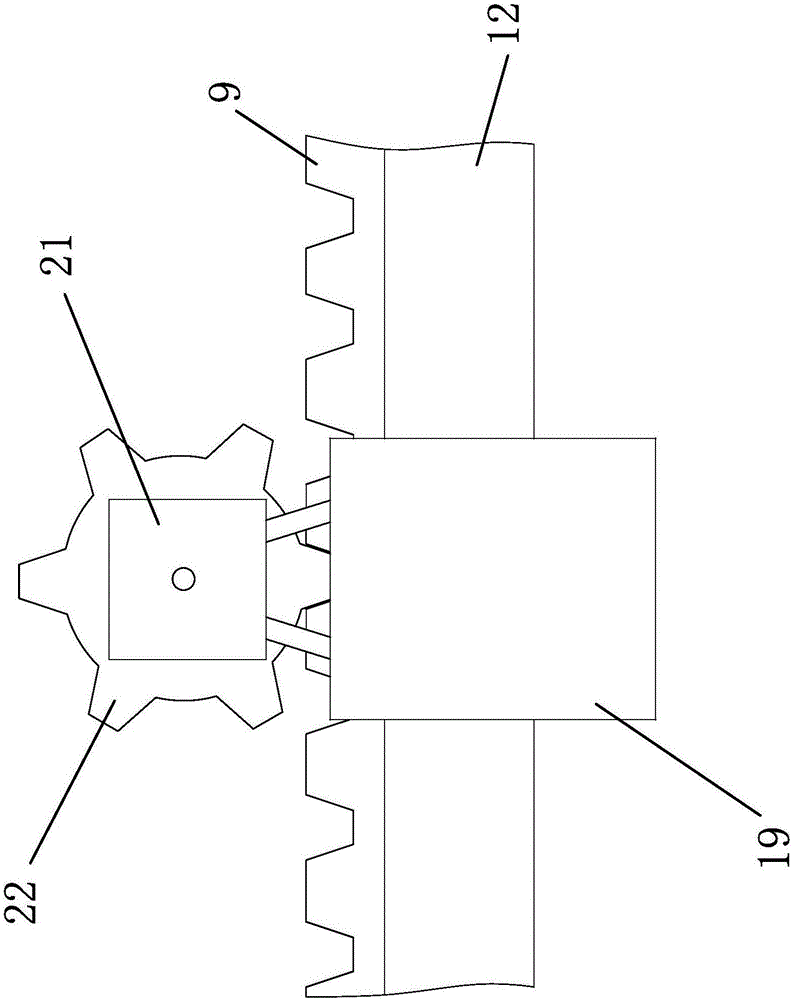

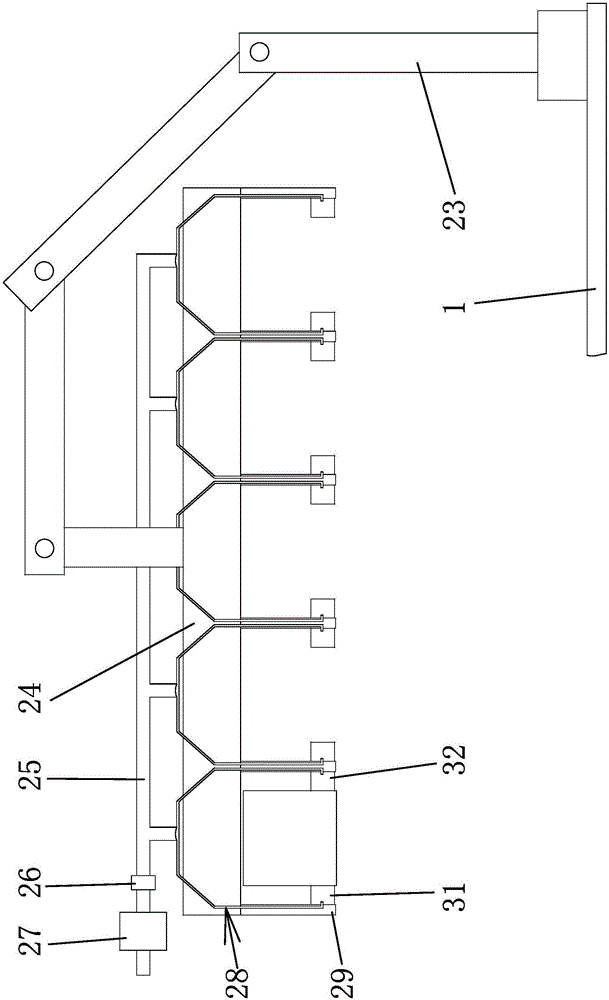

[0081] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0082] The production method of this five-proof wood, the method comprises the steps:

[0083] a. Pour dyeing agent, stabilizer, dredging agent, preservative and weighting agent into a common blender and mix to prepare a mixed medicinal solution. The stirring time is 10-20min; in the present embodiment, the stabilizer is Rosin, the dredging agent is ethanol ammonia, the weighting agent is maltodextrin, the preservative is the water boiled after mixing pepper and pepper, and the dyeing agent adopts existing auxiliary agents available on the market; the stirring time is 15min

[0084] b. Put the wood into a closed pressure impregnation tank, add the mixed chemical solution to the full tank, pressurize to 1.2-1.5MPa, keep it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com