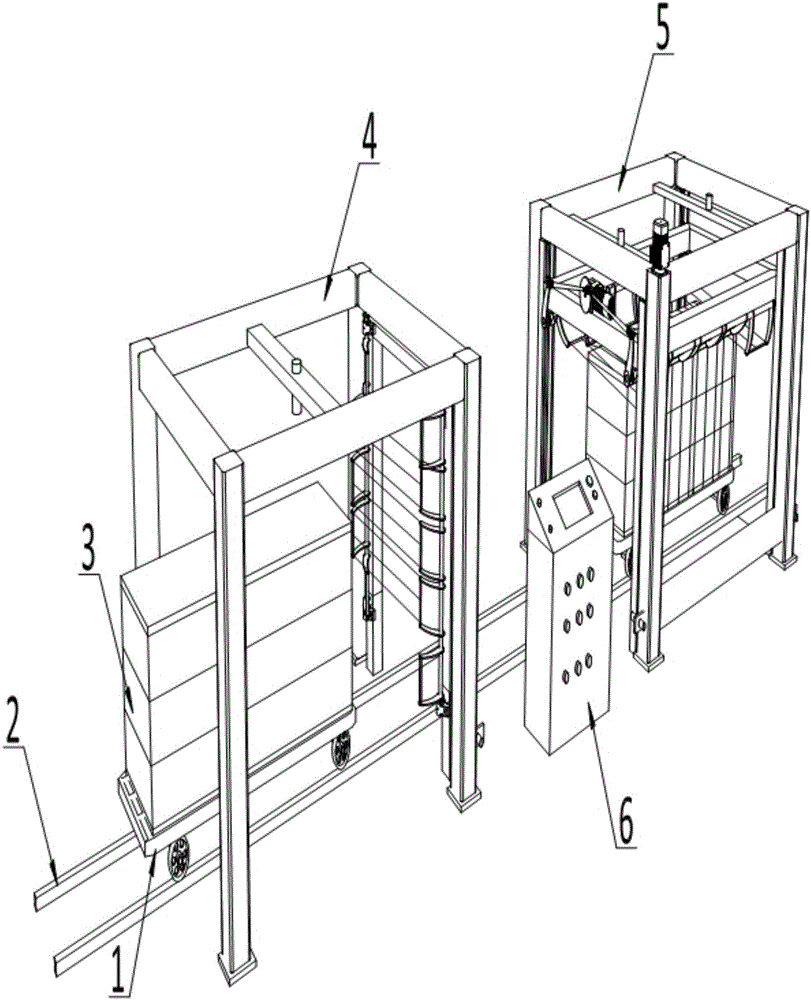

Aerated concrete cutting device and working method thereof

A technology of aerated concrete and cutting device, which is applied in the direction of working accessories, stone processing equipment, stone processing tools, etc., and can solve problems such as easy damage of steel saws, breaking of lifting and transportation, and affecting the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

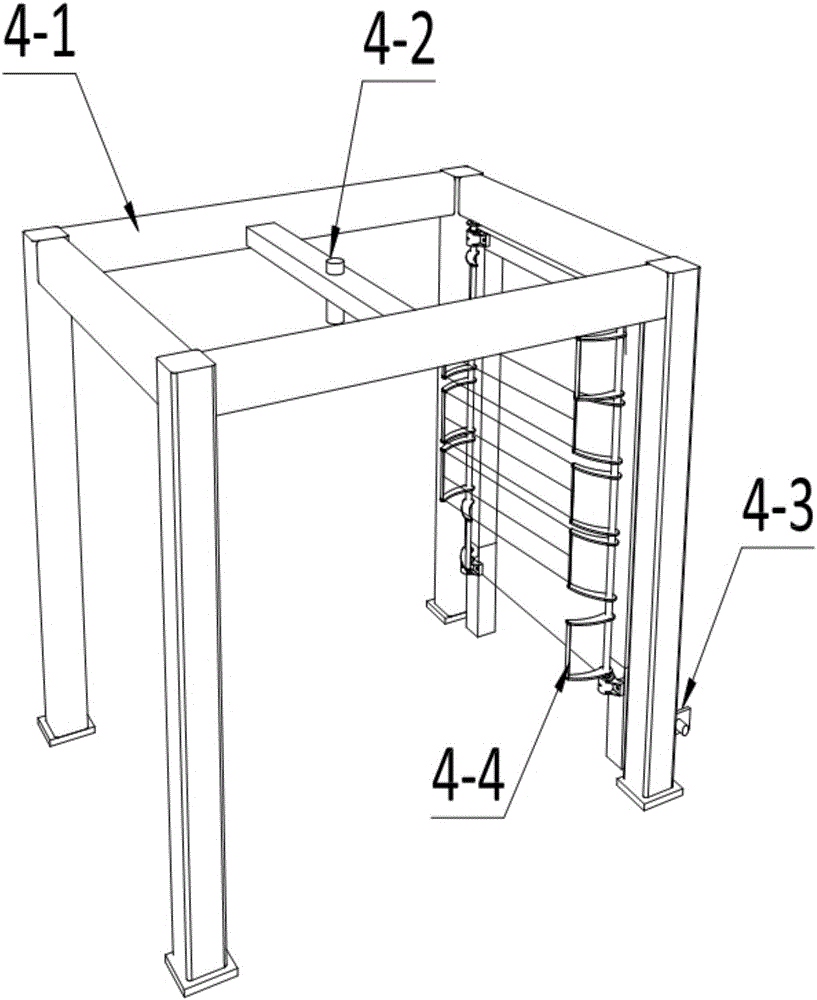

Method used

Image

Examples

Embodiment 1

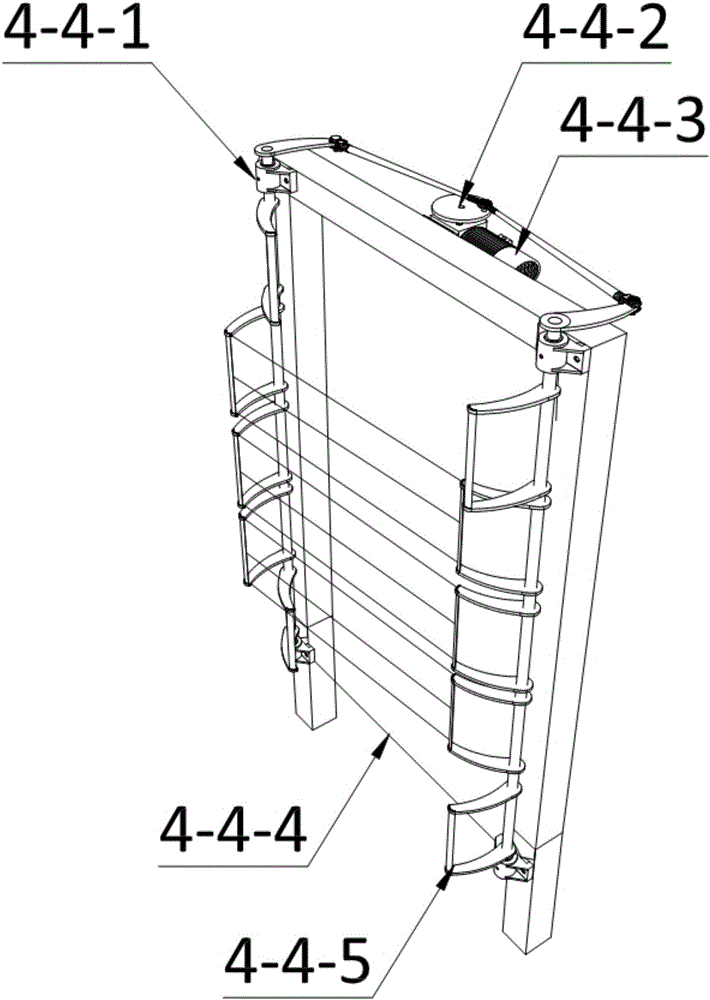

[0063] The transverse cutting line 4-4-4 and the longitudinal cutting line 5-5-4 of the present invention are manufactured according to the following steps, and are calculated in parts by weight:

[0064] Step 1: Add 1850 parts of ultrapure water with a conductivity of 5.75μS / cm into the reactor, start the stirrer in the reactor at a speed of 64rpm, start the heating pump, and raise the temperature in the reactor to 120°C; add in sequence 45 parts of cis-chloroformic acid-4-(1,1-dimethylethyl)cyclohexyl ester, peroxy[(1-methylethylene)di-4-cyclohexyl-1-ylidene]tetra( 1,1-dimethylethyl) 54 parts, N-[4-[bis(p-ethylenediaminophenyl)methylene]-2,5-cyclohexadiene-1-ylidene]-N-ethane 26 parts of ethylamine chloride, stirred until completely dissolved, adjusted the pH value to 5.7, adjusted the speed of the agitator to 124rpm, the temperature was 130°C, and the esterification reaction was carried out for 10 hours;

[0065] Step 2: Take 15 parts of ethyl sulfate of N-ethyl-N,N-dimeth...

Embodiment 2

[0070] The transverse cutting line 4-4-4 and the longitudinal cutting line 5-5-4 of the present invention are manufactured according to the following steps, and are calculated in parts by weight:

[0071] Step 1: Add 2250 parts of ultrapure water with a conductivity of 6.55μS / cm into the reactor, start the stirrer in the reactor at a speed of 96rpm, start the heating pump, and raise the temperature in the reactor to 150°C; add in order Cis-chloroformic acid-4-(1,1-dimethylethyl)cyclohexyl ester 65 parts, peroxy[(1-methylethylene)di-4-cyclohexyl-1-ylidene]tetra( 1,1-dimethylethyl) 85 parts, N-[4-[bis(p-ethylenediaminophenyl)methylene]-2,5-cyclohexadiene-1-ylidene]-N-ethane 41 parts of ethylamine chloride were stirred until completely dissolved, the pH was adjusted to 7.5, the speed of the agitator was adjusted to 155rpm, the temperature was 175°C, and the esterification reaction was carried out for 18 hours;

[0072] Step 2: Take 36 parts of ethyl sulfate of N-ethyl-N,N-dimethyl...

Embodiment 3

[0077] The transverse cutting line 4-4-4 and the longitudinal cutting line 5-5-4 of the present invention are manufactured according to the following steps, and are calculated in parts by weight:

[0078] Step 1: Add 2670 parts of ultrapure water with a conductivity of 8.25μS / cm into the reactor, start the stirrer in the reactor at a speed of 115rpm, start the heating pump, and raise the temperature in the reactor to 180°C; add in sequence 83 parts of cis-chloroformic acid-4-(1,1-dimethylethyl)cyclohexyl ester, peroxy[(1-methylethylene)di-4-cyclohexyl-1-ylidene]tetra( 1,1-dimethylethyl) 120 parts, N-[4-[bis(p-ethylenediaminophenyl)methylene]-2,5-cyclohexadiene-1-ylidene]-N-ethane 56 parts of ethylamine chloride, stirred until completely dissolved, adjusted the pH value to 8.5, adjusted the speed of the agitator to 185rpm, the temperature was 220°C, and the esterification reaction was carried out for 24 hours;

[0079] Step 2: Take 63 parts of ethyl sulfate of N-ethyl-N,N-dime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com