Machining process for rubber special for radial tire

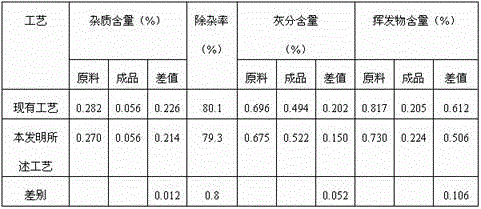

A radial tire and processing technology, applied in recycling technology, mechanical material recycling, plastic recycling, etc., can solve problems such as increased labor and electricity costs, inability to adapt to energy conservation and emission reduction, and increased overall equipment failure rate, and achieve the goal of technological innovation. The overall simplicity and practicality, the effect of improving the impurity removal rate of the equipment and reducing the overall failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

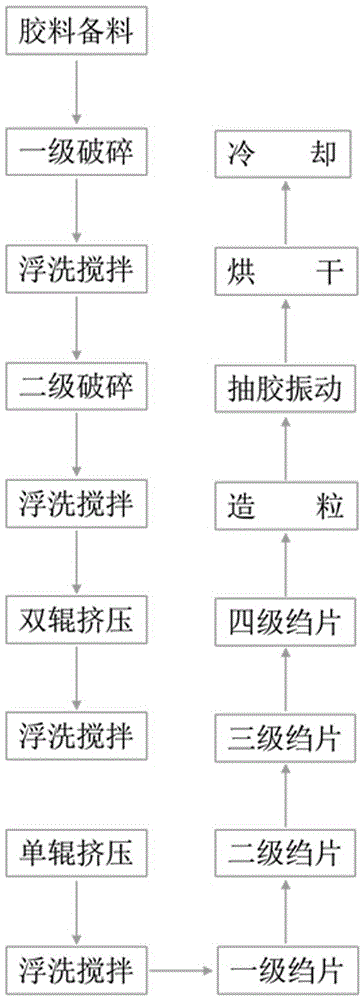

Embodiment 1

[0031]The recycled rubber raw materials are divided into two grades according to the evaluation results of "Dehong Gaoshen Rubber Industry Development Co., Ltd. Raw Material Control Quality Requirements", and the sundries on the surface of the recycled rubber raw materials are removed, and they are broken into rubber blocks of 40cm×10cm×8cm. The graded rubber raw materials after impurity removal are mixed in a weight ratio of 3:1 and sent to the crushing process. The mixed rubber material is crushed in the first stage to make a rubber block of 25cm×15cm×10cm, and the rubber block is stirred and mixed evenly in the floating washing water, and the floating washing time is 10 minutes; then the mixed rubber material is crushed in the second stage to make 5cm×5cm×2cm rubber block, and make the rubber block mix evenly in the floating washing water, and the floating washing time is 11min. Further, the mixed rubber material is first squeezed by double rollers, floated and washed, and t...

Embodiment 2

[0035] Divide the recycled rubber raw materials into two grades according to the evaluation results of "Dehong Gaoshen Rubber Industry Development Co., Ltd. Raw Material Control Quality Requirements", remove the sundries on the surface of the recycled rubber raw materials, and break them into rubber blocks of 50cm×15cm×20cm respectively. The graded rubber raw materials after impurity removal are mixed in a weight ratio of 1:3 and sent to the crushing process. The mixed rubber material is crushed in the first stage to make a rubber block of 10cm×10cm×4cm, and the rubber block is stirred and mixed evenly in the floating washing water, and the floating washing time is 11 minutes; then the mixed rubber material is crushed in the second stage to make 10cm×10cm×5cm rubber block, and make the rubber block mix evenly in the floating washing water. The floating washing time is 12min. Further, the mixed rubber material is first squeezed by double rollers, washed and stirred by floating, ...

Embodiment 3

[0039] Divide the recycled rubber raw materials into two grades according to the evaluation results of "Dehong Gaoshen Rubber Industry Development Co., Ltd. Raw Material Control Quality Requirements", remove the sundries on the surface of the recycled rubber raw materials, and break them into rubber blocks of 45cm×12cm×14cm. The graded rubber raw materials after impurity removal are mixed in a weight ratio of 2:1 and sent to the crushing process. The mixed rubber material is crushed in the first stage to make a rubber block of 18cm×12cm×7cm, and the rubber block is stirred and mixed evenly in the floating washing water, and the floating washing time is 12 minutes; then the mixed rubber material is crushed in the second stage to make 7cm×7cm×3cm rubber block, and make the rubber block mix evenly in the floating washing water. The floating washing time is 13min. Further, the mixed rubber material is first squeezed by double rollers, floated and washed, and then squeezed by single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com