Waste organic glass extrusion splitter

A plexiglass and pyrolysis machine technology, which is applied in the field of waste plexiglass extrusion cracking machine, can solve the problems of difficult temperature control, environmental pollution, and cleaning difficulties, and achieve the effect of ensuring sufficient cracking, taking into account product purity, and avoiding over cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further description will be made below in conjunction with drawings and embodiments.

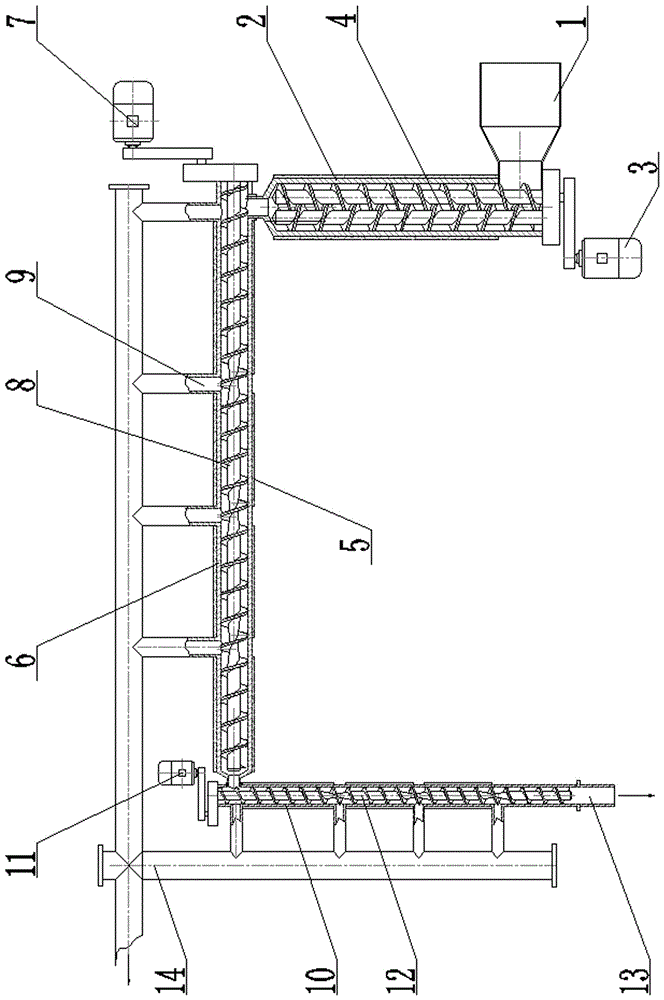

[0016] figure 1 Shown: a waste plexiglass extrusion cracking machine includes a waste plexiglass feed port 1, an extrusion cylinder 2, an extrusion motor 3, an extrusion screw 4, a heating ring 5, a gasification cylinder 6, and a gasification motor 7. Gasification screw 8 , gasification port 9 , discharge cylinder 10 , discharge motor 11 , waste screw 12 , waste outlet 13 and gasification pipeline 14 . The extrusion cylinder 2, the gasification cylinder 6 and the discharge cylinder 10 are vertically connected successively, and the cylinders of the extrusion cylinder 2, the gasification cylinder 6 and the discharge cylinder 10 are all wrapped with a heating ring 5, and the extrusion The head end of the cylinder 2 is provided with a waste plexiglass feed port 1, and the extrusion cylinder 2 is provided with a double extrusion screw 4 that interlocks to convey the material, and any extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com