A water hydraulic buoyancy adjustment device and method

A buoyancy adjustment and water hydraulic technology, which is applied to underwater ships, transportation and packaging, underwater operation equipment, etc., can solve the problems of affecting the stability of the device, unused deep-sea pressure, and the device cannot work, and achieves a simple structure and a solution to the problem. Miniaturization and deep dive into technical bottlenecks and the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

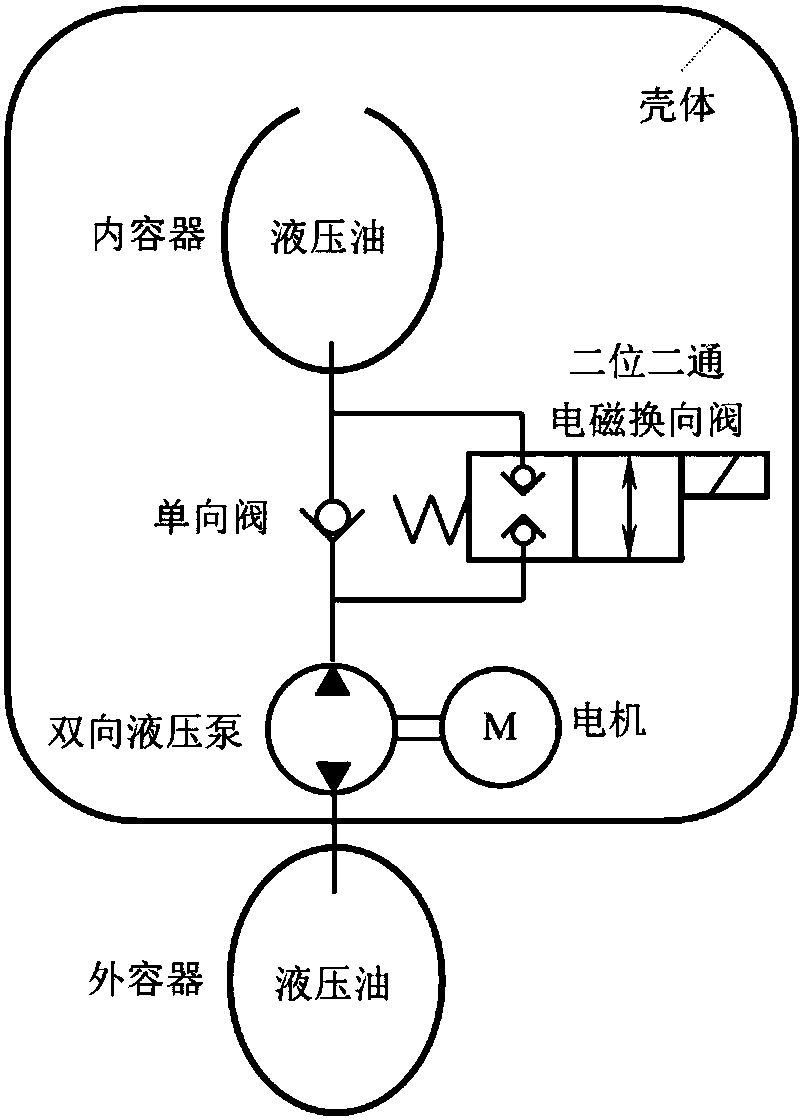

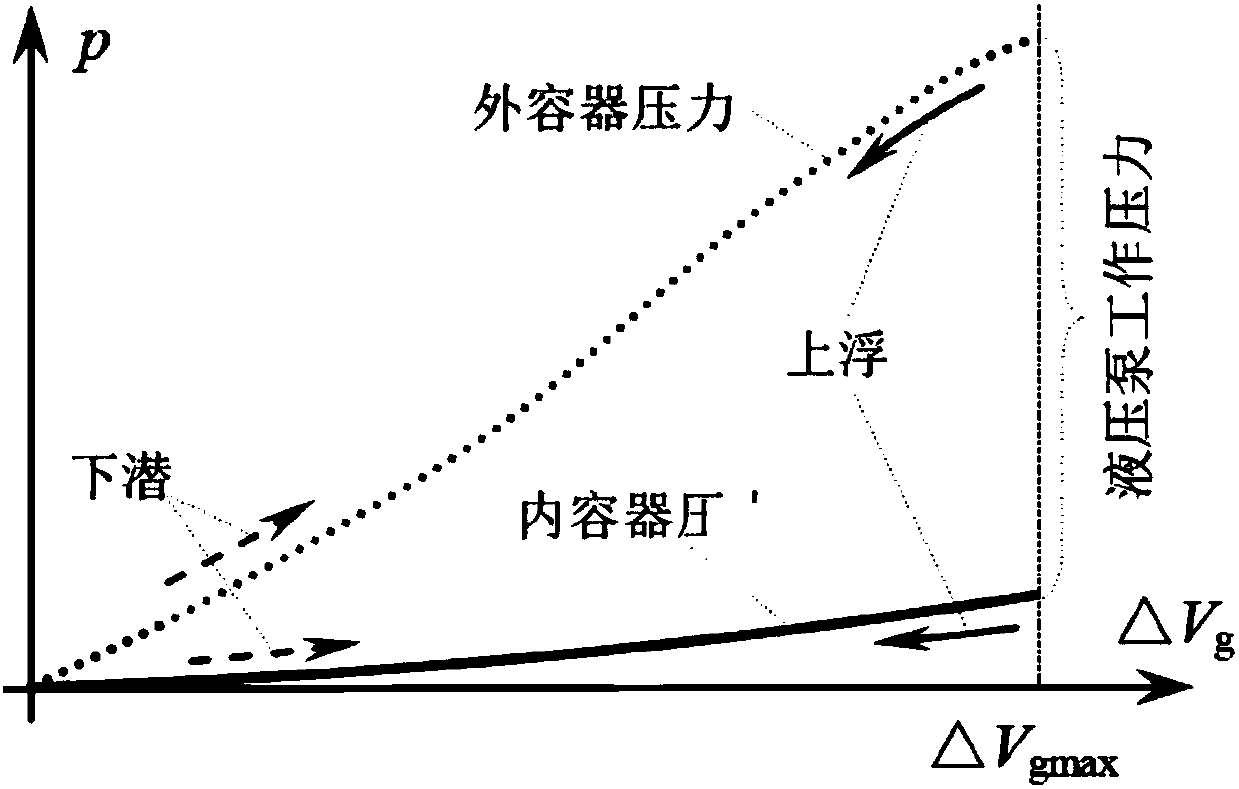

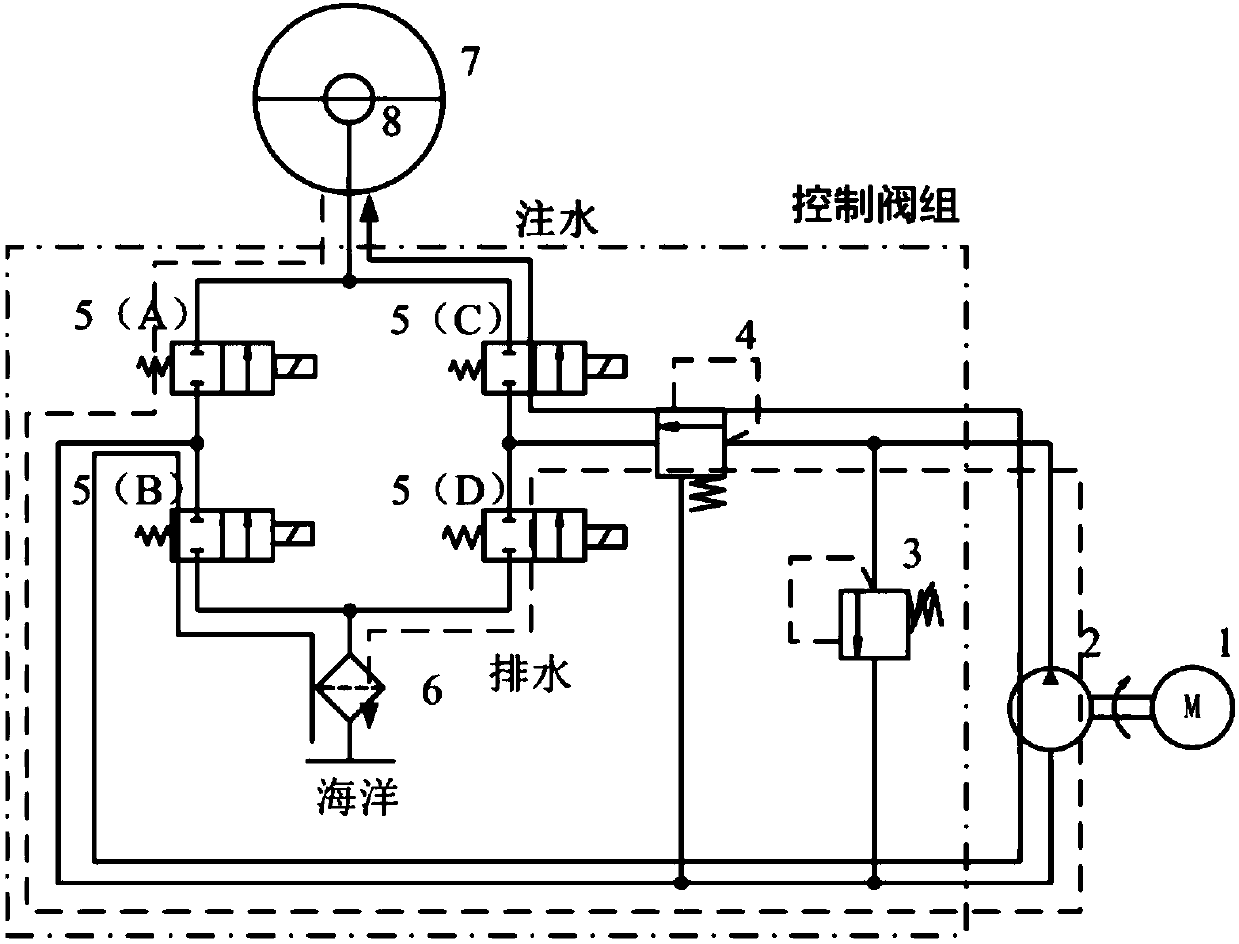

[0035] Example 1, such as Figure 4 As shown, the present embodiment discloses a water hydraulic buoyancy adjusting device. The device includes a housing 41 filled with a certain pressure of inert gas; A water hydraulic hydraulic control check valve 43, a first container 44 for filling water, a two-way acting water hydraulic pump-motor 45, a second container 46 for filling water, a second hydraulic hydraulic control check valve 47; described content The container 42 is an elastic soft container whose volume changes with the volume of water contained therein; the inner container 42 passes through the above-mentioned first water hydraulic control check valve 43, the first container 44, the two-way acting water hydraulic pump-motor 45, the The second container 46 and the second water hydraulic control check valve 47 communicate with the water environment outside the housing 41 so as to drain or absorb water, and the water inlet of the first water hydraulic control check valve 43 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com