Efficient seawater desalting plant

A water collecting device and high-efficiency technology, which are applied in seawater treatment, general water supply conservation, chemical instruments and methods, etc., can solve the problems of large volume, low seawater desalination rate and efficiency, and high energy consumption, and achieve small thermal resistance and appearance. Small structure, the effect of improving heat exchange efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

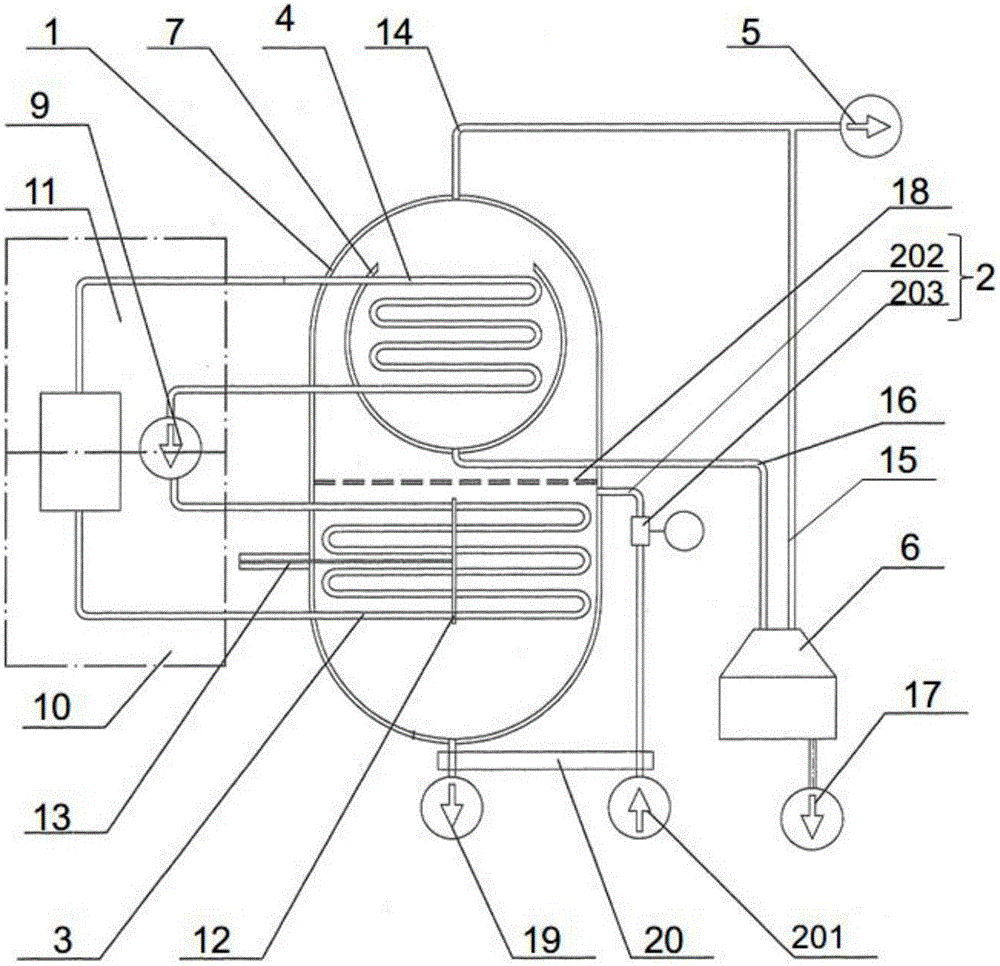

[0035] Such as figure 1 and figure 2 As shown, the present invention discloses a high-efficiency seawater desalination device, including a shell 1, a water injection device 2, an evaporator 3, a condenser 4, a vacuum device 5 and a water collection device 6, and the vacuum device 5 passes through a first The vacuum pipeline 14 communicates with the housing 1, and communicates with the water collecting device 6 through the second vacuum pipeline 15. The vacuum device 5 is a water jet extractor, a steam jet extractor, a vane vacuum pump or a vacuum pump. One of the vacuum pumps, the vacuum device 5 continuously discharges the partially condensed gas in the casing 1 and the water collecting device 6 and maintains a high vacuum state of the two.

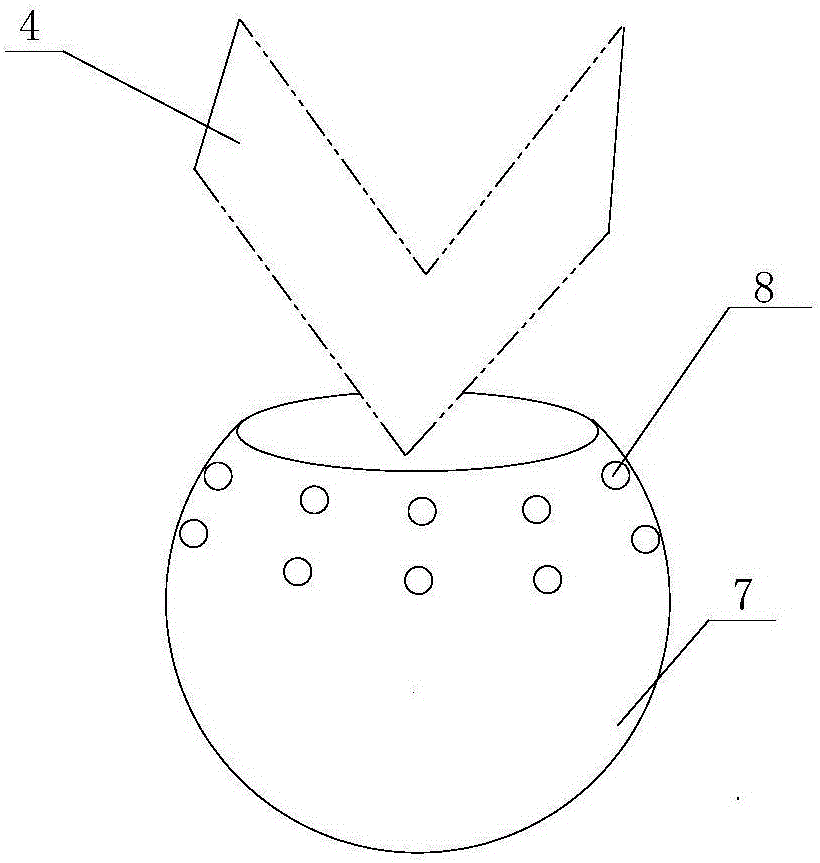

[0036] The housing 1 is divided into two cavities connected up and down, the condenser 4 and the evaporator 3 are respectively arranged in the upper and lower cavities of the housing 1, the evaporator 3, the evaporator 3 The condenser...

Embodiment 2

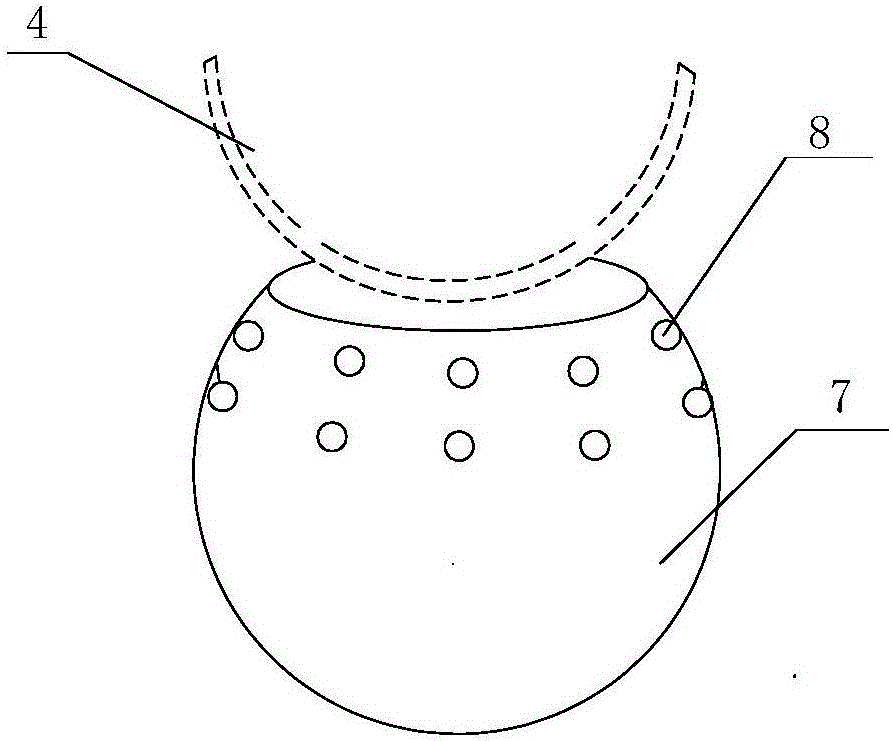

[0049] Such as figure 1 and image 3 As shown, the present invention discloses a high-efficiency seawater desalination device, including a shell 1, a water injection device 2, an evaporator 3, a condenser 4, a vacuum device 5 and a water collection device 6, and the vacuum device 5 passes through a first The vacuum pipeline 14 communicates with the housing 1, and communicates with the water collecting device 6 through the second vacuum pipeline 15. The vacuum device 5 is a water jet extractor, a steam jet extractor, a vane vacuum pump or a vacuum pump. One of the vacuum pumps, the vacuum device 5 continuously discharges the partially condensed gas in the casing 1 and the water collecting device 6 and maintains a high vacuum state of the two.

[0050] The housing 1 is divided into two cavities connected up and down, the condenser 4 and the evaporator 3 are respectively arranged in the upper and lower cavities of the housing 1, the evaporator 3, the evaporator 3 The condenser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com