A low-quality waste heat utilization system in a steel plant and its application method

A low-quality, steel plant technology, applied in chemical instruments and methods, general water supply conservation, water/sludge/sewage treatment, etc. The effect of reducing overall energy consumption and pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

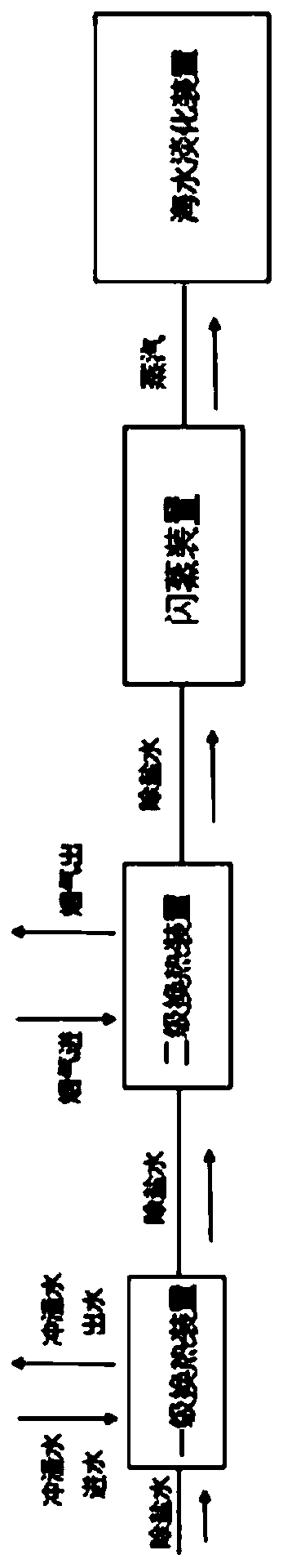

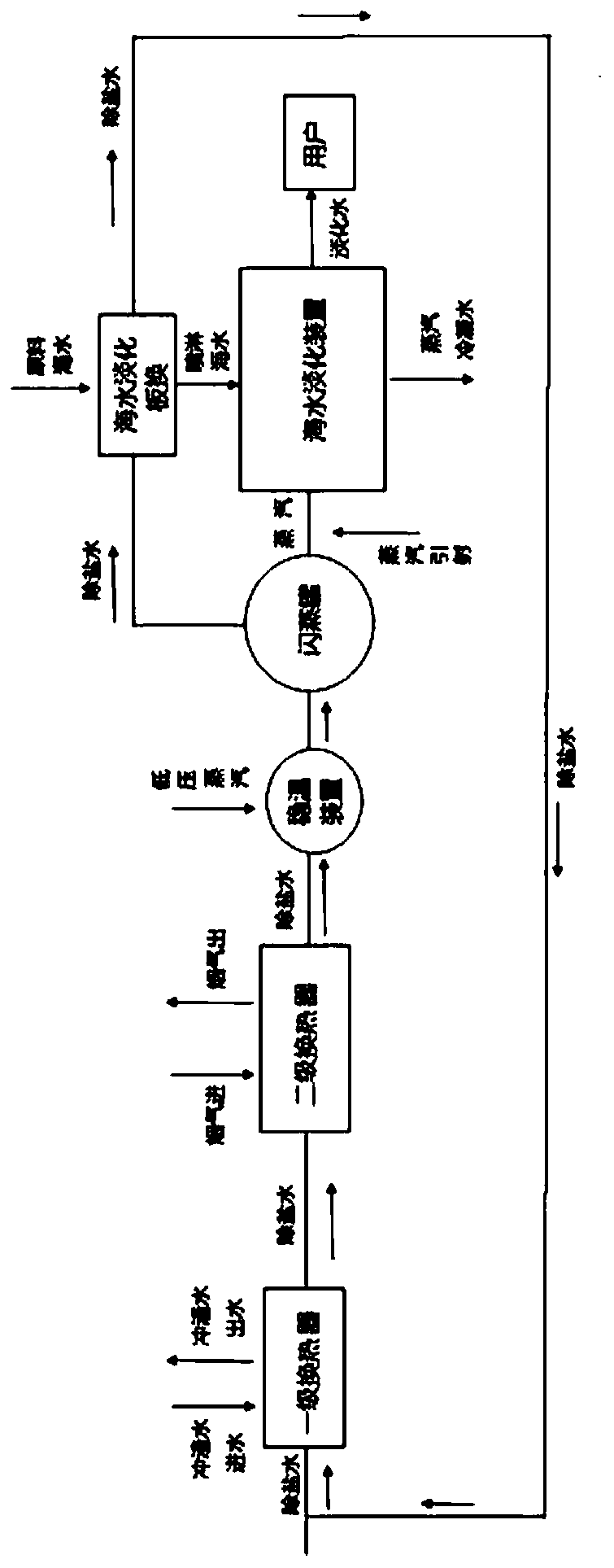

[0040] like figure 2 As shown, the low-quality waste heat utilization system of the iron and steel plant in Embodiment 1 of the present invention includes:

[0041] A primary water-to-water heat exchanger for transferring heat between a first fluid and a second fluid, the primary water-to-water heat exchanger comprising: a first channel fluid passage for the first fluid, the A first channel fluid passage is provided with a first inlet and a first outlet; and a second channel fluid passage for a second fluid is provided with a second inlet and a second outlet, the first and The fluid passages of the second channel are adjacently arranged, and the first inlet, the first outlet, the second inlet and the second outlet are separately arranged at the end of the first-stage water-water heat exchanger, and the first fluid is brine, the second fluid is blast furnace slag flushing water;

[0042] The secondary air-water heat exchanger and the primary water-water heat exchanger are us...

Embodiment 2

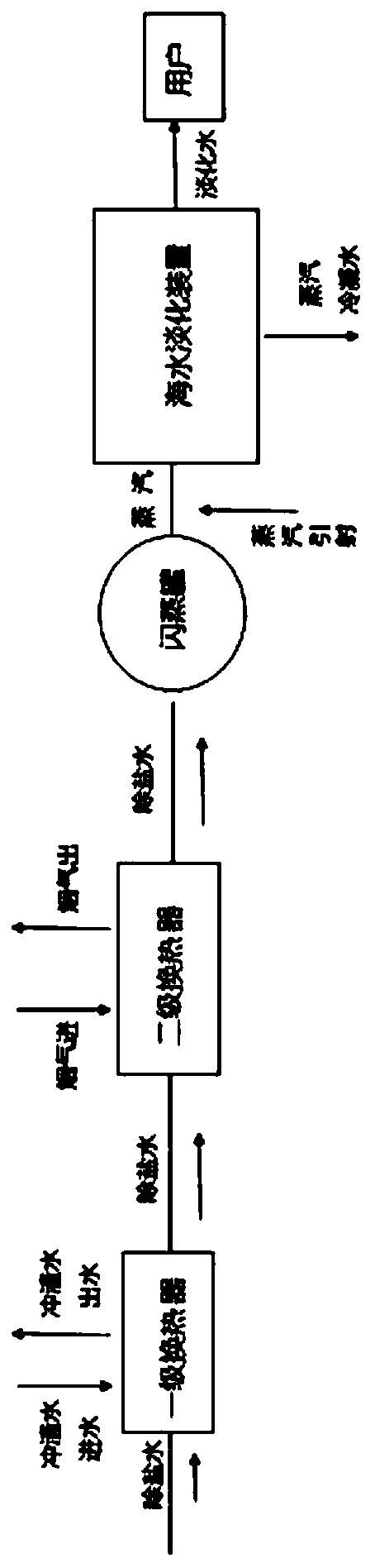

[0047] like image 3 As shown, the low-quality waste heat utilization system of the iron and steel plant in Embodiment 2 of the present invention includes:

[0048] A primary water-to-water heat exchanger for transferring heat between a first fluid and a second fluid, the primary water-to-water heat exchanger comprising: a first channel fluid passage for the first fluid, the A first channel fluid passage is provided with a first inlet and a first outlet; and a second channel fluid passage for a second fluid is provided with a second inlet and a second outlet, the first and The fluid passages of the second channel are adjacently arranged, and the first inlet, the first outlet, the second inlet and the second outlet are separately arranged at the end of the first-stage water-water heat exchanger, and the first fluid is brine, the second fluid is blast furnace slag flushing water;

[0049] The secondary air-water heat exchanger and the primary water-water heat exchanger are use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com