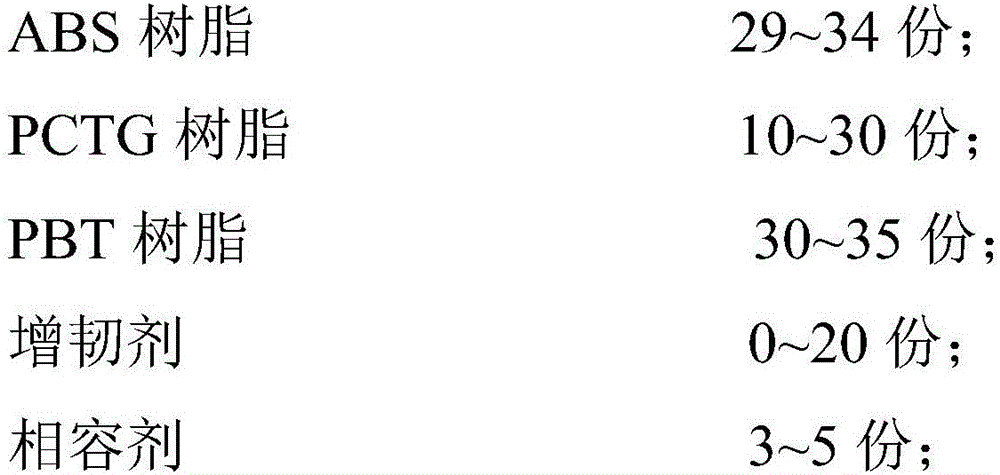

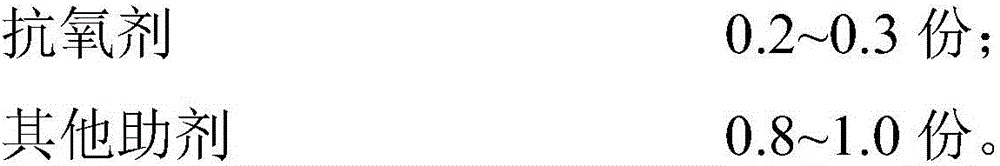

ABS (acrylonitrile butadiene styrene)/PBT (polybutylene terephthalate)/PCTG (polyethylene terephthalate glycol) composite material high in low-temperature toughness and solvent resistance and preparation method thereof

A technology of solvent resistance and low temperature toughness, applied in the field of polymer composite materials and its processing, can solve the problems of stress cracking, good solvent resistance low temperature toughness, and high rigidity of PC materials, so as to improve the low temperature falling ball toughness and low temperature falling ball impact. Improves, overcomes the effect of increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with embodiment and comparative example, further set forth advantage of the present invention and notable feature, but be not limitation of the present invention, especially the data in the embodiment do not limit the consumption of each composition in the invention.

[0021] Raw material selection:

[0022] Select the following resins with different characteristics in the following embodiments, and their names and corresponding characteristics are defined as follows:

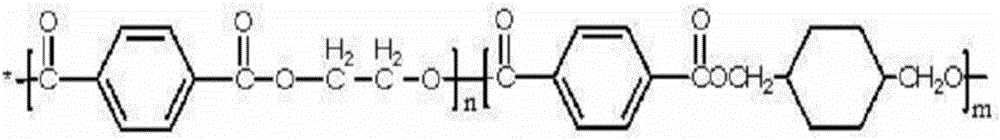

[0023] PCTG(110): The glass transition temperature of PCTG resin is 110°C;

[0024] PBT (0.6): The intrinsic viscosity of PBT resin is 0.6dl / g;

[0025] PBT (0.8): The intrinsic viscosity of PBT resin is 0.8dl / g;

[0026] PBT (1.1): The intrinsic viscosity of PBT resin is 1.1dl / g;

[0027] ABS(0.3): The average particle size distribution of butadiene rubber used for ABS resin is small, ranging from 0.2-0.5 μm, and the particle size D50≈0.3 μm;

[0028] ABS (1.3): The average part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com