Aluminum alloy plate for motorcycle hub and preparation method of aluminum alloy plate

A technology for aluminum alloy plates and motorcycles, applied in the field of aluminum alloys, can solve the problems of poor uniformity of heat treatment components, inability to completely eliminate internal stress, and insufficient forging pressure, and achieve complete grain breakage, small internal stress, and reduced internal stress. effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

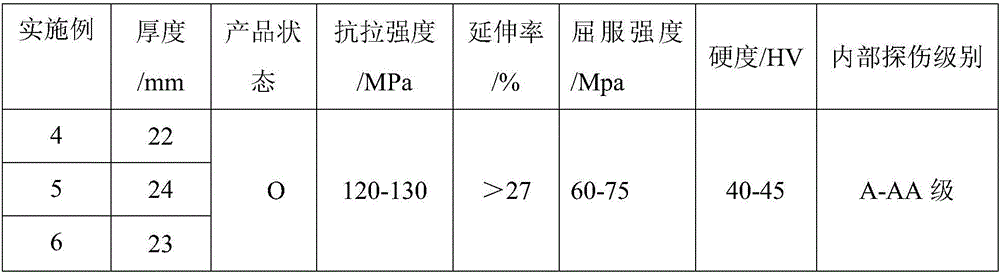

Examples

Embodiment 1

[0037] An aluminum alloy plate for a motorcycle wheel hub, the mass percentage of each element in the aluminum alloy plate is as follows:

[0038] Si is 0.45%, Fe is 0.3%, Cu is 0.15%, Mn is 0.1%, Mg is 0.85%, Cr is 0.18%, Zn is 0.1%, Ti is 0.03%, and the rest is Al.

Embodiment 2

[0040] An aluminum alloy plate for a motorcycle wheel hub, the mass percentage of each element in the aluminum alloy plate is as follows:

[0041] Si is 0.55%, Fe is 0.4%, Cu is 0.20%, Mn is 0.02%, Mg is 0.95%, Cr is 0.23%, Zn is 0.02%, Ti is 0.04%, and the rest is Al.

Embodiment 3

[0043] An aluminum alloy plate for a motorcycle wheel hub, the mass percentage of each element in the aluminum alloy plate is as follows:

[0044] Si is 0.50%, Fe is 0.35%, Cu is 0.18%, Mn is 0.05%, Mg is 0.90%, Cr is 0.20%, Zn is 0.05%, Ti is 0.04%, and the rest is Al.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com