Machining process for metal tube

A processing technology and metal tube technology, applied in the direction of metal material coating technology, etc., can solve the problems of easy rusting, affecting the processing of metal tubes, and rust inhibitor affecting the performance of electroplating, etc., to improve hardness, improve corrosion resistance and The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

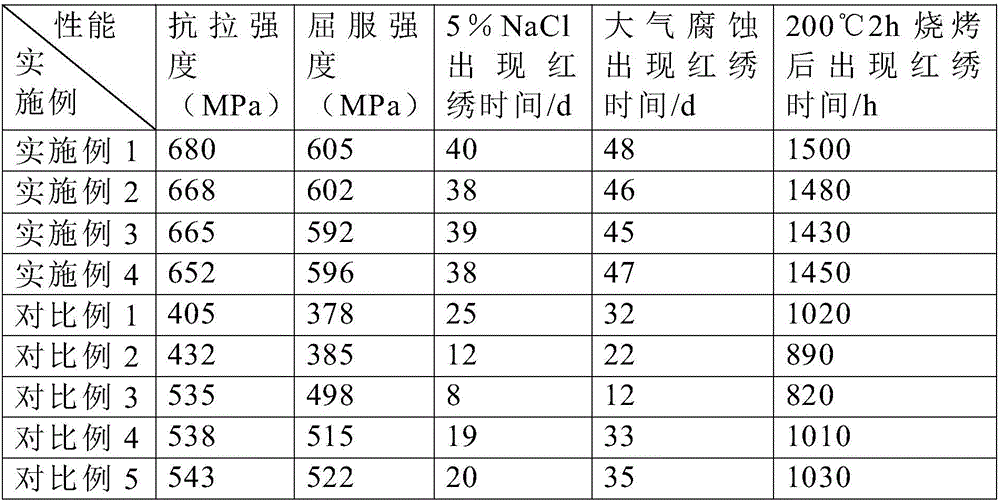

Examples

Embodiment 1

[0031] Embodiment 1: the processing technology of metal pipe

[0032] The alloy steel is processed and formed to obtain a metal pipe blank; the composition elements and mass percentages of the alloy steel are: C: 0.15%, Cr: 1.4%, Si: 0.18%, Mn: 0.95%, Al: 0.04%, N: 0.012%, Ti: 0.15%, P≤0.015%, S≤0.018%, and the balance is Fe and unavoidable impurities.

[0033] Treat the metal tube blank in the electroplating solution at 25°C for 80 minutes; the composition of the electroplating solution is: zinc oxide 6g / L, sodium hydroxide: 120g / L, nickel: 0.8g / L, additive: 220ml.

[0034] The metal tube blanks after electroplating are subjected to water washing, light treatment, passivation treatment, water washing, and antirust treatment in sequence to obtain metal tube semi-finished products; among them, the light treatment is a common and common light production process, and the composition of the passivation solution is: cerium nitrate : 1.8g / L, Accelerator H 2 o 2 :6ml / L, H 3 BO 3...

Embodiment 2

[0036] Embodiment 2: processing technology of metal pipe

[0037] Processing the alloy steel to obtain a metal pipe blank; the composition elements and mass percentages of the alloy steel are: C: 0.16%, Cr: 1.38%, Si: 0.22%, Mn: 1.08%, Al: 0.042%, N: 0.001%, Ti: 0.18%, P≤0.015%, S≤0.018%, and the balance is Fe and unavoidable impurities.

[0038] Treat the metal tube blank in the electroplating solution at 28°C for 100 minutes; the composition of the electroplating solution is: zinc oxide 6g / L, sodium hydroxide: 125g / L, nickel: 0.7g / L, additive: 280ml.

[0039] The metal tube blanks after electroplating are subjected to water washing, light treatment, passivation treatment, water washing, and antirust treatment in sequence to obtain metal tube semi-finished products; among them, the light treatment is a common and common light production process, and the composition of the passivation solution is: cerium nitrate : 2.2g / L, Accelerator H 2 o 2 :7ml / L, H 3 BO 3 Buffer: 2.2g / ...

Embodiment 3

[0041] Embodiment 3: processing technology of metal pipe

[0042] The alloy steel is processed and formed to obtain a metal pipe blank; the composition elements and mass percentages of the alloy steel are: C: 0.12%, Cr: 1.5%, Si: 0.15%, Mn: 1.15%, Al: 0.03%, N: 0.008%, Ti: 0.22%, P≤0.015%, S≤0.018%, and the balance is Fe and unavoidable impurities.

[0043] Treat the metal tube blank in the electroplating solution at 30°C for 50 minutes; the composition of the electroplating solution is: zinc oxide 7g / L, sodium hydroxide: 130g / L, nickel: 1g / L, additive: 300ml.

[0044] The metal tube blanks after electroplating are subjected to water washing, light treatment, passivation treatment, water washing, and antirust treatment in sequence to obtain metal tube semi-finished products; among them, the light treatment is a common and common light production process, and the composition of the passivation solution is: cerium nitrate : 2.5g / L, Accelerator H 2 o 2 :8ml / L, H 3 BO 3 Buffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com