Water turbine wear-resistant casting and welding structure guide vane and manufacturing method thereof

A technology of casting and welding structure and water turbine, which is applied in the directions of hydropower generation, mechanical equipment, machine/engine, etc., can solve the problems of inability to repair welding of workpieces, complicated casting process, high manufacturing cost, etc., to ensure corrosion resistance and eliminate residual stress. , make easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

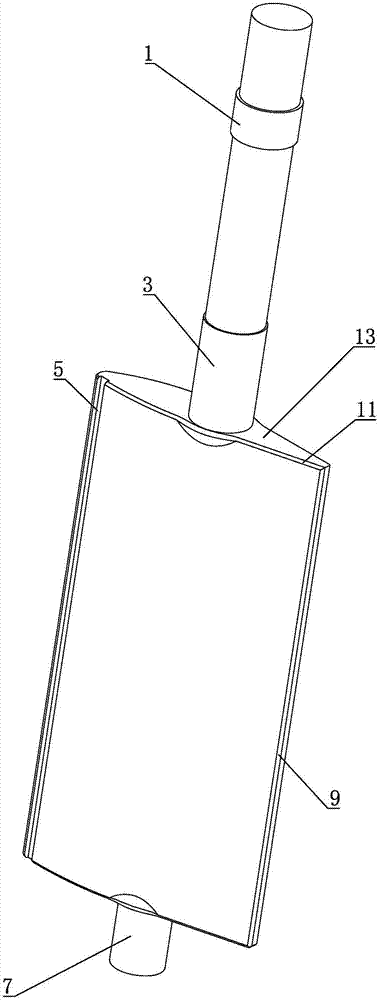

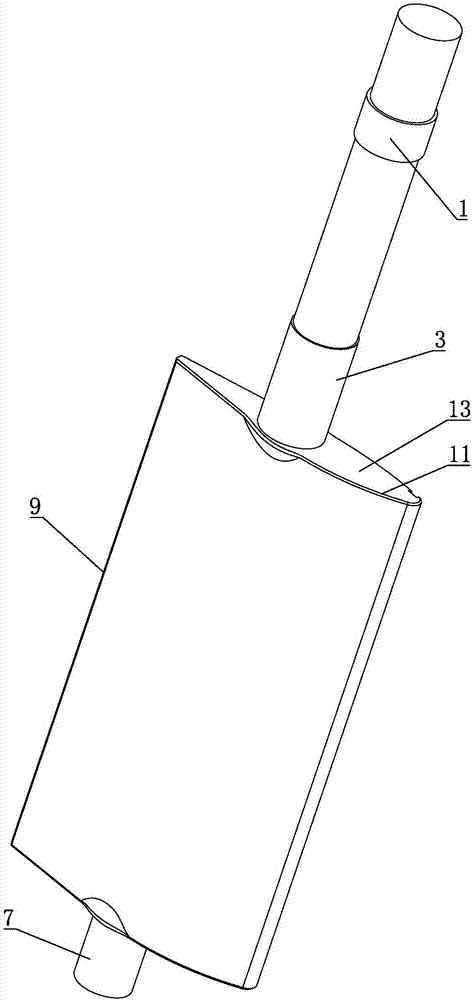

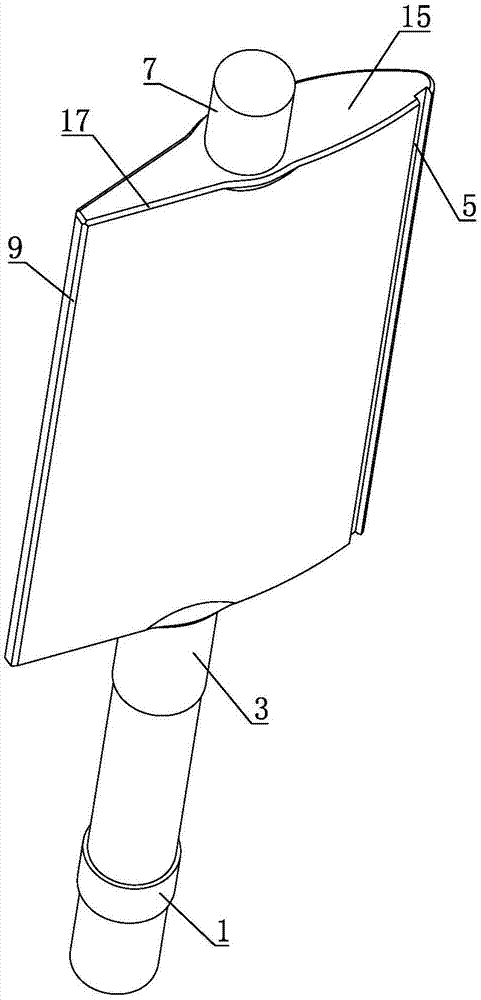

[0064] The guide vane of the water turbine with wear-resistant cast-welded structure includes the guide vane body and the guide vane shaft; the improvements of the present invention are:

[0065] (i) The guide vane body is composed of a cast carbon steel guide vane body (51), a stainless steel upper end plate (45), a stainless steel lower end plate (49), and a stainless steel tail plate (47). Materials such as ZG230-450 and ZG20MnSi can be used for casting ordinary carbon steel. The stainless steel plate can be made of 0Cr18Ni9, 1Cr18Ni9Ti.

[0066] The cast carbon steel guide vane body has a body upper end surface (13), a lower body end surface (15), a body tail side surface, and a body head side surface; the upper end surface of the body is inverted with the upper end surface welding angle (11) of the body; The lower end surface of the main body is inverted by the welding corner (17) of the lower end surface of the main body; the two sides of the main body tail side surface are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com