Preparation method for nitrogenous hybrid active standard gas

A standard gas and mixed standard technology, which is applied in the field of preparation of standard mixed gas, can solve problems such as measurement deviation and instability, and achieve the effects of more efficient preparation process, simplified operation, and improved customer satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a nitrogen-containing mixed active standard gas, the method comprising the following steps:

[0024] Step 1, connect the bottle to be inflated to the mixed standard gas filling device, open the bottle valve, fill the bottle with a nitrogen-containing mixed active standard gas with a concentration higher than the predetermined concentration of the finished product, and close the bottle valve after reaching 0.5-3 MPa;

[0025] Step 2, remove the cylinder and let it stand for 48-96 hours;

[0026] Step 3, release the air bottle, and vacuum for 3-15 minutes;

[0027] Step 4, close the vacuum valve, open the filling valve, and fill in the nitrogen-containing mixed active standard gas with a concentration higher than the predetermined concentration of the finished product;

[0028] Step 5, filling high-purity nitrogen in proportion so that the nitrogen-containing mixed active standard gas in the bottle to be inflated reaches a pr...

Embodiment

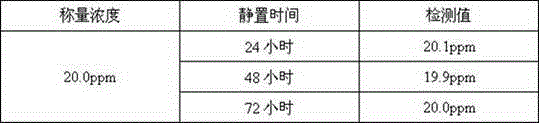

[0033] Taking the preparation of 20×10-6 mol / mol (20ppm) hydrogen sulfide standard gas in nitrogen in a 4-liter bottle as an example, the preparation process is as follows:

[0034] 1. Take a pre-treated (baked at 80°C, vacuumed for 16-24 hours), and a 4-liter bottle to be inflated that has passed the inspection before filling.

[0035] 2. Connect the bottle to be inflated to the mixed standard gas filling device, open the bottle valve, and fill the bottle with 10 times the concentration of the finished product, that is, 200×10-6 mol / mol (200ppm) hydrogen sulfide mixed gas in nitrogen, until Close the bottle valve after 1Mpa.

[0036] 3. Remove the cylinder and let it stand for 72 hours.

[0037] 4. Connect the bottle to be inflated to the device, release the air bottle, and vacuum for 3 minutes.

[0038] 5. Close the vacuum valve, open the filling valve, and fill in 200×10-6 mol / mol (200ppm) hydrogen sulfide mixed gas in nitrogen, 44g.

[0039] 6. Charge 396g of high-purit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com