A copper-aluminum interface alloy composite bus bar used in power transmission and distribution equipment

A copper-aluminum composite busbar, power transmission and distribution equipment technology, applied in the direction of metal/alloy conductors, circuits, conductive materials, etc., can solve the problems of poor electrical conductivity, high failure rate, low manufacturing cost, etc., to enhance electrical conductivity, enhance Bending resistance, effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

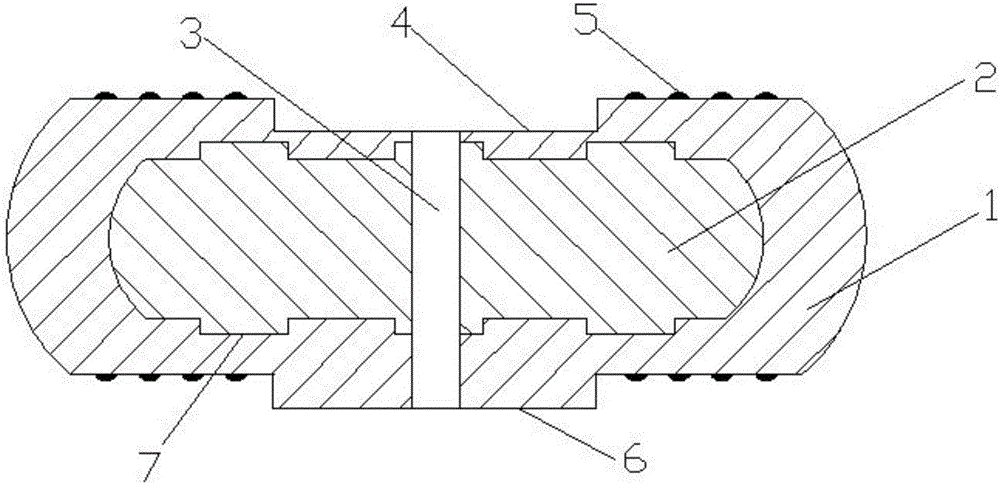

[0014] figure 1 It is a structural schematic diagram of a copper-aluminum interface alloy composite busbar used in power transmission and distribution equipment provided by the present invention. The layer is an aluminum layer 2, and the copper layer 1 is coated on the outer surface of the aluminum layer 2 to form a flat oval shape; the outer surface of the aluminum layer 2 is provided with a plurality of ribs 7 along the length direction, and the inner surface of the copper layer 1 There is a groove A matching the rib 7; the upper surface of the end of the copper-aluminum composite busbar body is provided with a groove B, and the lower surface is provided with a bump 6 matching the groove B; There are also a number of protrusions 5 on the two opposite sides of the end of the copper-aluminum composite busbar body,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com