Flexible lithium ion battery and manufacturing method therefor

A lithium-ion battery, flexible technology, applied in the direction of electrolyte battery manufacturing, secondary battery, battery pack components, etc., can solve the problems of small cell damage, complex process, complex assembly process, etc. Simple and convenient material retrieval effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

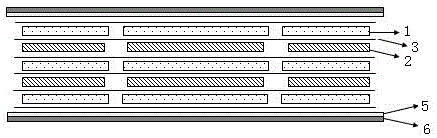

[0048] Such as figure 1 As shown, the structure diagram of the flexible lithium-ion battery provided in this embodiment includes a sealed package 6 and a battery pack and electrolyte disposed inside the sealed package 6. The battery pack includes a positive electrode sheet 1, a negative electrode sheet 2 and a set The separator 3 between the positive electrode sheet 1 and the negative electrode sheet 2; the positive electrode ear 7 connected to the positive electrode sheet and the negative electrode ear 8 connected to the negative electrode sheet are arranged on one side of the battery pack, and the positive electrode ear 7 and the negative electrode ear 8 pass through the sealed package Part 6; the electrolyte is filled in the sealed package 6. In this embodiment, the isolation film 3 can be one or more of ceramic film, PE film, PP film or PE and PP composite film; the sealed package 6 is an aluminum-plastic film. The flexible lithium-ion battery provided in this embodiment ...

Embodiment 2

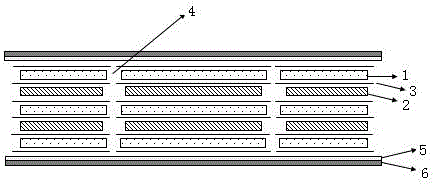

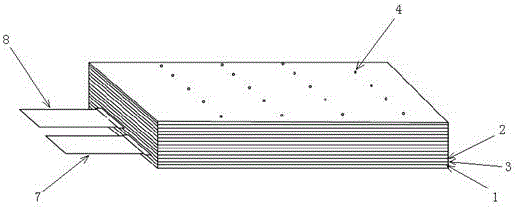

[0050] This embodiment is a further improvement on the basis of Embodiment 1, as figure 2 and image 3 As shown, it also includes a flexible fixing assembly 5, the flexible fixing assembly 5 is arranged inside the sealed package 6, the positive electrode sheet 1, the negative electrode sheet 2 and the separator 3 are provided with through holes 4 corresponding to and coincident with each other. The fixing component 5 passes through the positive electrode sheet 1 , the negative electrode sheet 2 and the separator 3 through the through hole 4 and fixes the battery pack and the sealed package 6 . In this embodiment, the flexible fixing component 5 is a polymer material, which may be one of polyethylene, polypropylene, polyvinyl chloride, polybutylene terephthalate and polystyrene.

[0051] The manufacturing method of flexible lithium-ion battery described above, comprises the following steps:

[0052] Step 1, the positive electrode sheet and the negative electrode sheet are pu...

Embodiment 3

[0061] The positive electrode sheet, negative electrode sheet, separator, etc. required by the flexible lithium-ion battery of the present invention are currently commonly used battery materials, and commercially available products can be used or prepared by oneself, which has no effect on the realization of the purpose of the present invention. A kind of present invention is provided below The specific preparation method of the flexible lithium-ion battery is as follows:

[0062] Preparation of lithium-ion full battery: the positive electrode sheet, negative electrode sheet, and separator are laminated to make lithium-ion battery cells;

[0063] Positive plate material area size: 80mm*50mm (length*width);

[0064] Negative sheet area size: 82mm*52mm;

[0065] Isolation film width: 54mm; Isolation film is 16um Al 2 o 3 Ceramic separator.

[0066] Before lamination, the positive electrode and negative electrode are perforated, the aperture of the positive electrode is 1.8m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com