Method for treating wastewater containing ammonia

A treatment method and wastewater technology, applied in the direction of oxidized water/sewage treatment, etc., can solve inappropriate problems, achieve the effects of less harmful gases, easy decomposition, and low concentration of residual oxidants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

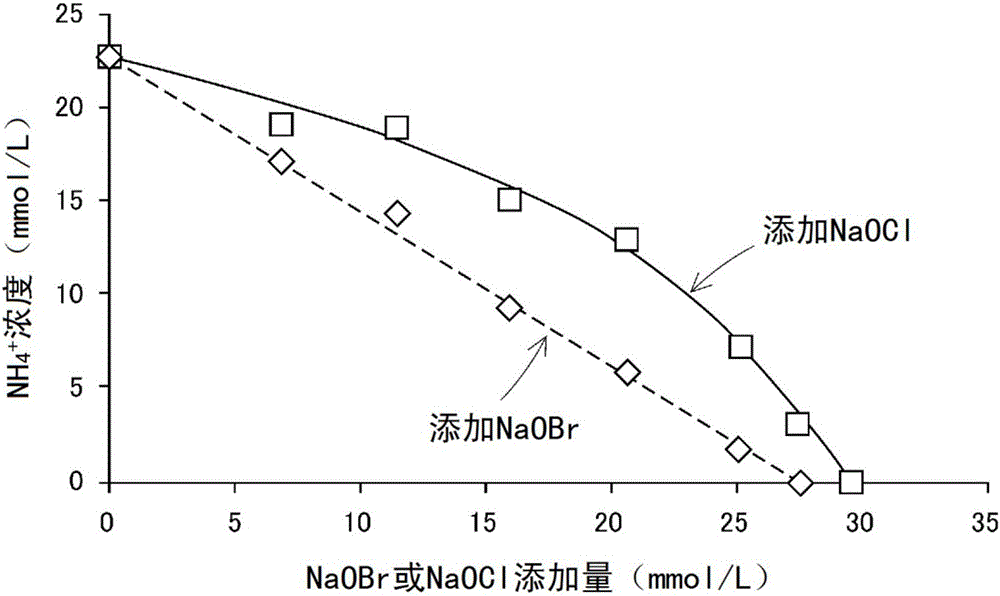

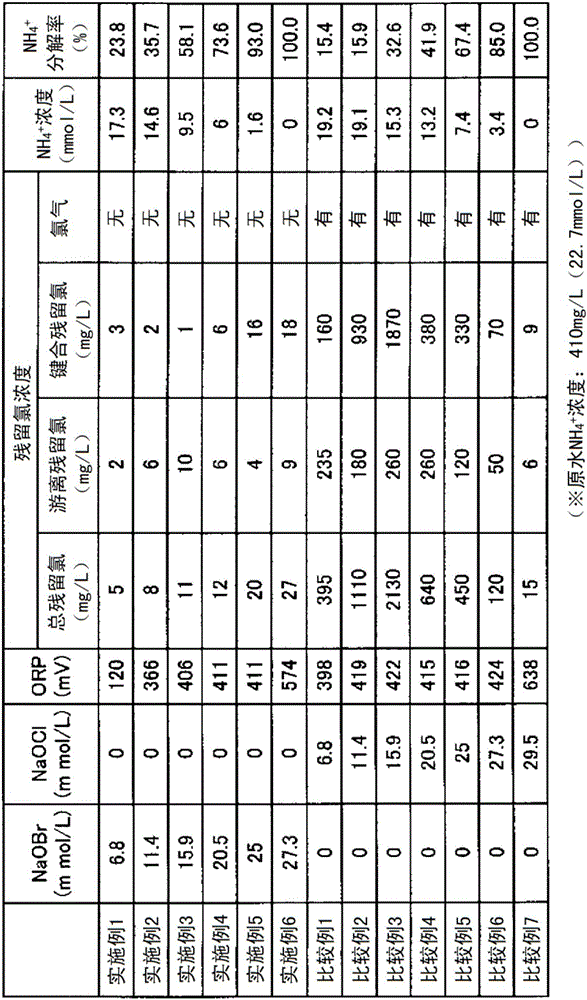

[0050] [Examples 1 to 6 (treatment with liquid containing sodium hypobromite)]

[0051] As test water, steel mill wastewater of the following water quality was used.

[0052] pH: 8.2

[0053] Ammonium ion concentration: 410mg / L (22.7mmol / L)

[0054] TOC: 21mg / L

[0055] ORP: 236mV

[0056] For a liquid containing sodium hypobromite as a chemical solution, a sodium bromide solution with a concentration of 40 wt% and a sodium hypochlorite solution with a concentration of 12 wt% are mixed to form a ratio of NaBr:NaOCl=1:1 (molar ratio) to generate hypobromide Sodium acid liquid.

[0057] 1000 mL of test water was stored in a glass container, the water temperature was kept at 50°C, and the pH was adjusted to 9.6 with NaOH, then the sodium hypobromite aqueous solution was added. The reaction time was set to 5 minutes.

[0058] Table 1 shows the amount of sodium hypobromite added, the residual chlorine concentration, ORP, ammonium ion concentration, and ammonium ion decomposit...

Embodiment 7~21

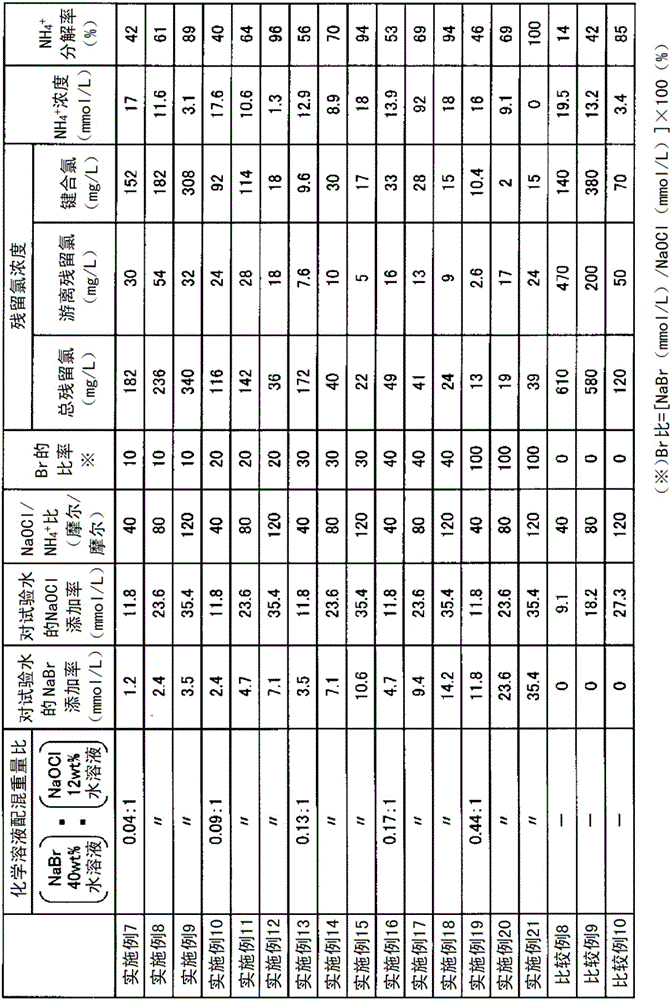

[0067] [Examples 7 to 21 (treatment with sodium hypobromite and sodium hypochlorite)]

[0068] As test water, steel mill wastewater of the following water quality was used.

[0069] pH: 8.3

[0070] Ammonium ion concentration: 532mg / L (29.5mmol / L)

[0071] TOC: 22mg / L

[0072] ORP: 90mV

[0073] As the liquid containing sodium hypobromite and sodium hypochlorite, the liquid which produced sodium hypobromite by mixing the sodium bromide solution of 40 wt% concentration and the sodium hypochlorite aqueous solution of 12 wt% concentration by the weight ratio of Table 2 was used.

[0074] 1000 mL of test water was stored in a glass container, and the water temperature was kept at 50° C., and after pH was adjusted to 9.6 with NaOH, an aqueous solution of sodium hypobromite was added. The reaction time was set to 5 minutes.

[0075] Table 2 shows the amount of chemical reagents added (converted to the ratio of NaBr and NaOCl added to the test water), the residual chlorine conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com