Snail-killing granule using sawdust as main carrier

A technology of granules and sawdust, which is applied in the agricultural field to achieve the effects of convenient transportation and application, avoiding poor effect and abundant sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

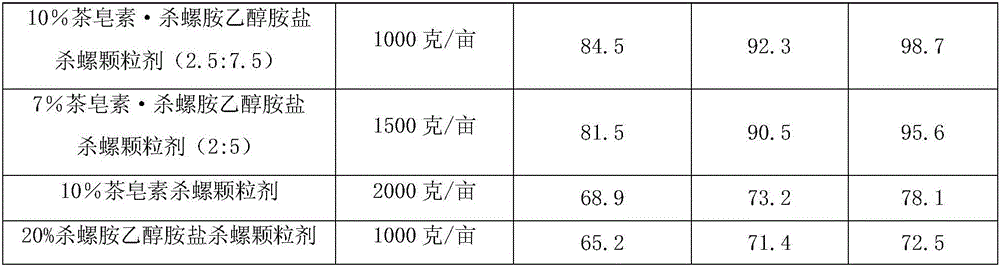

[0016] Example 1: 10% tea saponin·spiroxamine ethanolamine salt snail-killing granules

[0017] Raw material ratio by weight: tea saponin 2.5%, spiroxamine ethanolamine salt 7.5%, polyvinyl alcohol 5% (binder), polycarboxylate 3%, sodium lauryl sulfate 2.5%, bentonite 10% , sawdust make up to 100%.

Embodiment 2

[0018] Example 2: 15% tea saponin·spiroxamine ethanolamine salt snail killing granule

[0019] Raw materials by weight: 5% tea saponin, 10% spiroxamine ethanolamine salt, 4% polyvinyl alcohol (binder), 5% polycarboxylate, 2.5% sodium lauryl sulfate, 10% kaolin , sawdust make up to 100%.

Embodiment 3

[0020] Example 3: 12.5% tea saponin·spiroxamine ethanolamine salt molluscicide granule

[0021] Raw material ratio by weight: 2.5% tea saponin, 10% ethanolamine salt of spiroxamine, 5% polyvinyl alcohol (binder), 3% polycarboxylate, 2.5% sodium lauryl sulfate, white carbon black 10%, sawdust make up to 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com