Rice fresh-keeping processing method

A processing method and rice technology, applied in the fields of food processing and grain processing, can solve the problem of high power consumption per ton of rice, and achieve the effects of reducing storage costs, insect-proof storage costs, and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

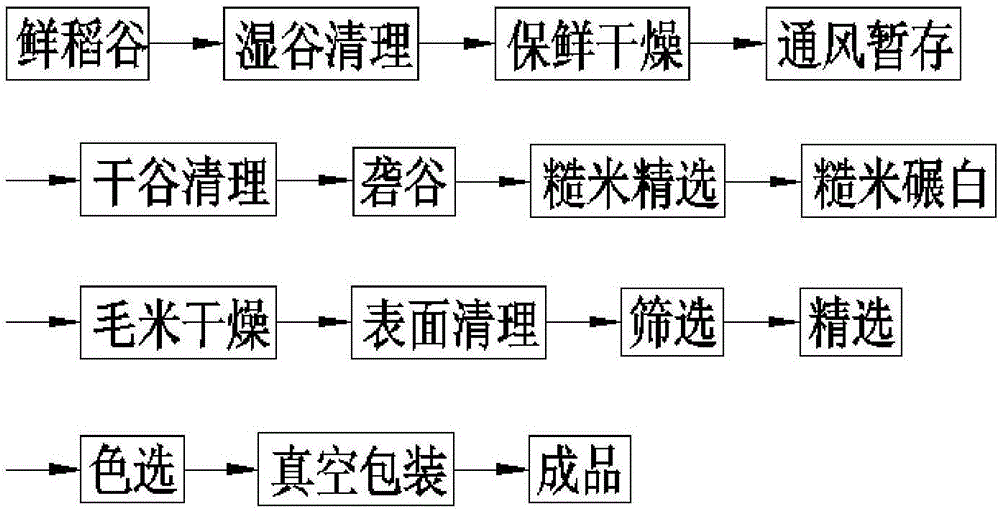

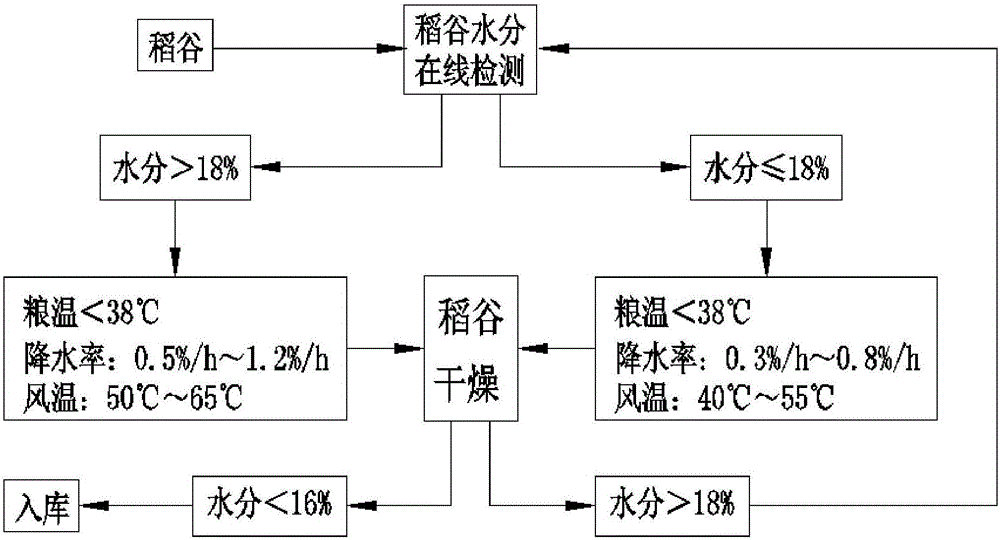

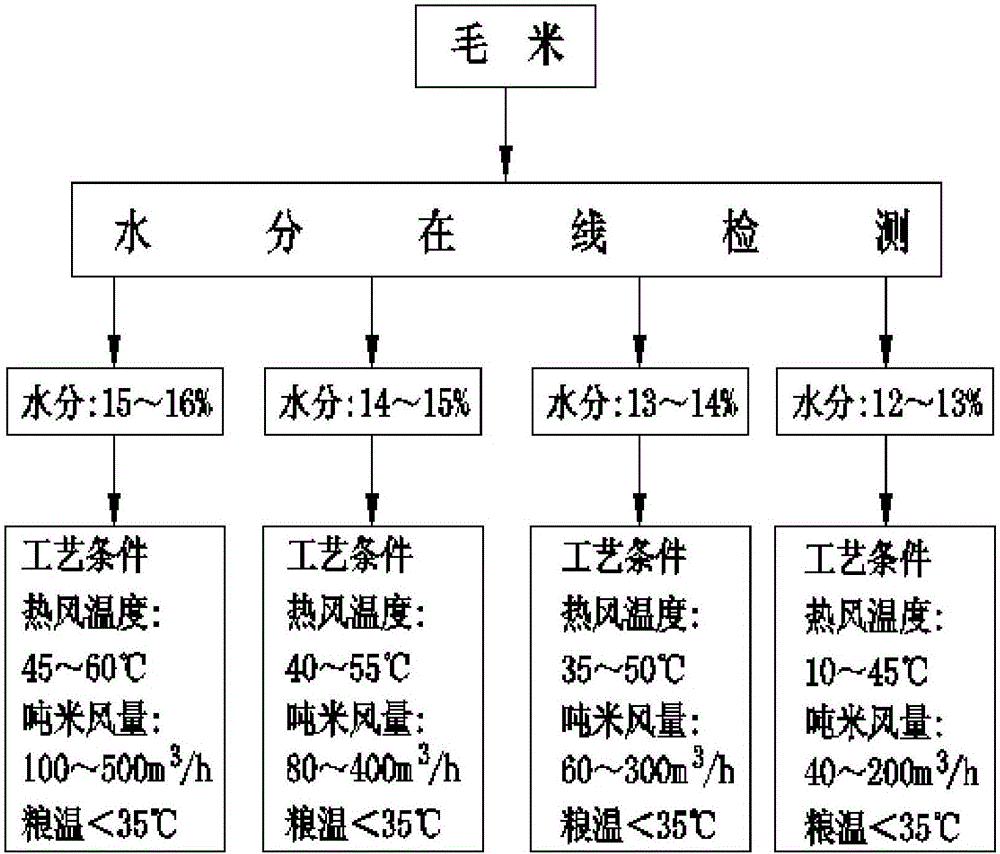

[0018] Embodiment 1 sees attached figure 1 ----attached image 3 .

[0019] (1) According to the existing conventional method, select the paddy that has just been harvested and has a moisture content between 25% and 26%.

[0020] (2) Cleaning, grading, and impurity removal are carried out to the paddy according to existing conventional methods to become clean and fresh paddy.

[0021] (3) Put the net fresh grain into a batch dryer with a volume of 30 tons, and use hot air at 50°C to 65°C to dry the rice in the dryer, and control the temperature of the grain in the machine to be less than 38°C. The precipitation rate is between 0.6% and 1.1%. The clean and fresh grains are circulated and dried in the dryer, and the moisture value of the clean and fresh grains is detected online. When the moisture value detected online is greater than 18%, repeat the above cycle drying process; when the moisture value detected online is less than or equal to 18%, control the temperature of t...

Embodiment 2

[0026] Embodiment 2 sees attached figure 1 ----attached image 3 .

[0027] (1) Transport the rice with a moisture content of 15% to 16% from the warehouse to the rice processing workshop according to a conventional method.

[0028] (2) Cleaning, grading, husking, separating paddy and whitening the rice according to conventional methods to obtain raw rice.

[0029] (3) Put the raw rice into the dryer, and carry out circulation drying according to the fresh-keeping and drying process of raw rice, so that the moisture content of the raw rice is between 12% and 12.5%.

[0030] (4) Cool the gross rice, control the ventilation temperature in the cool rice warehouse at 5°C to 30°C, and the ventilation rate per ton of gross rice at 30m 3 / h~60m 3 / h, cold rice time is 20 to 40 hours.

[0031] (5) According to conventional methods, sorting, selecting, color sorting, polishing, measuring and packaging are carried out, which is the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com