Photo-Fenton catalyst Fe3O4/rGO/TiO2, preparation method and applications thereof

A catalyst and Guangfen technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that catalysts are not easy to recycle, have small specific surface area, and low degradation efficiency and other problems, to achieve the effect of improving Fenton's catalytic performance, high catalytic performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

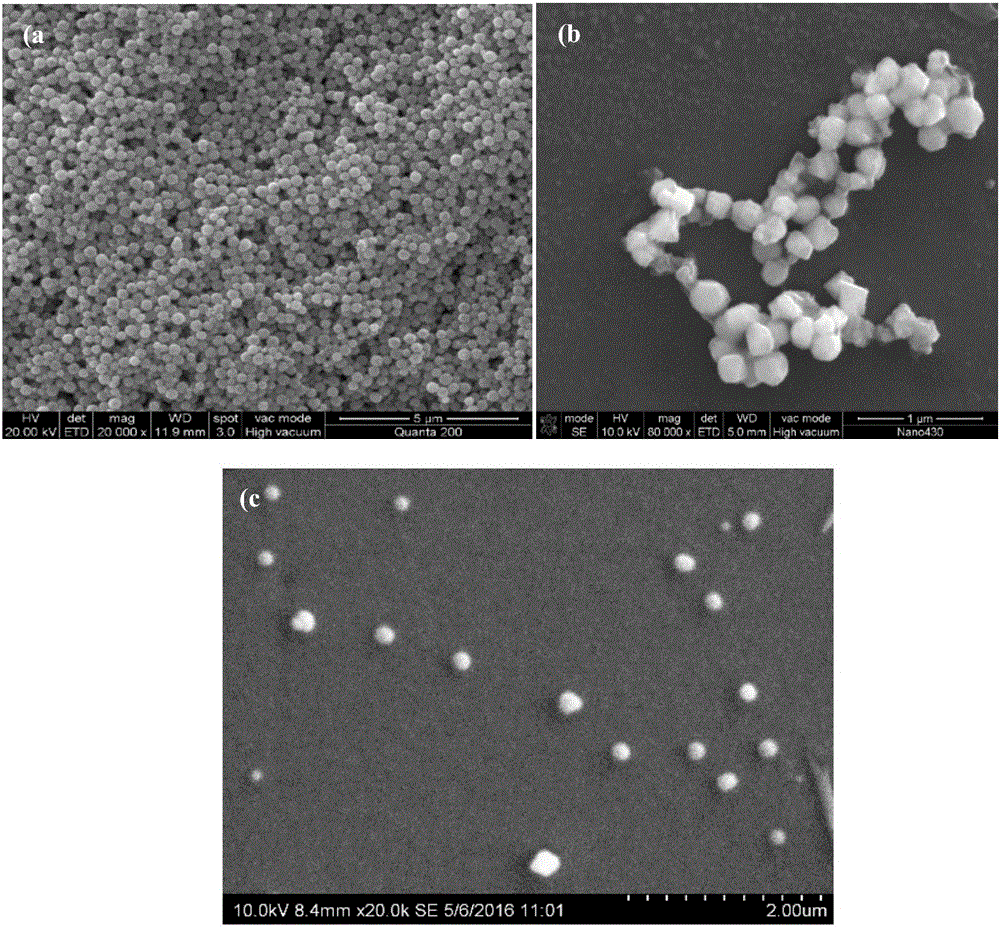

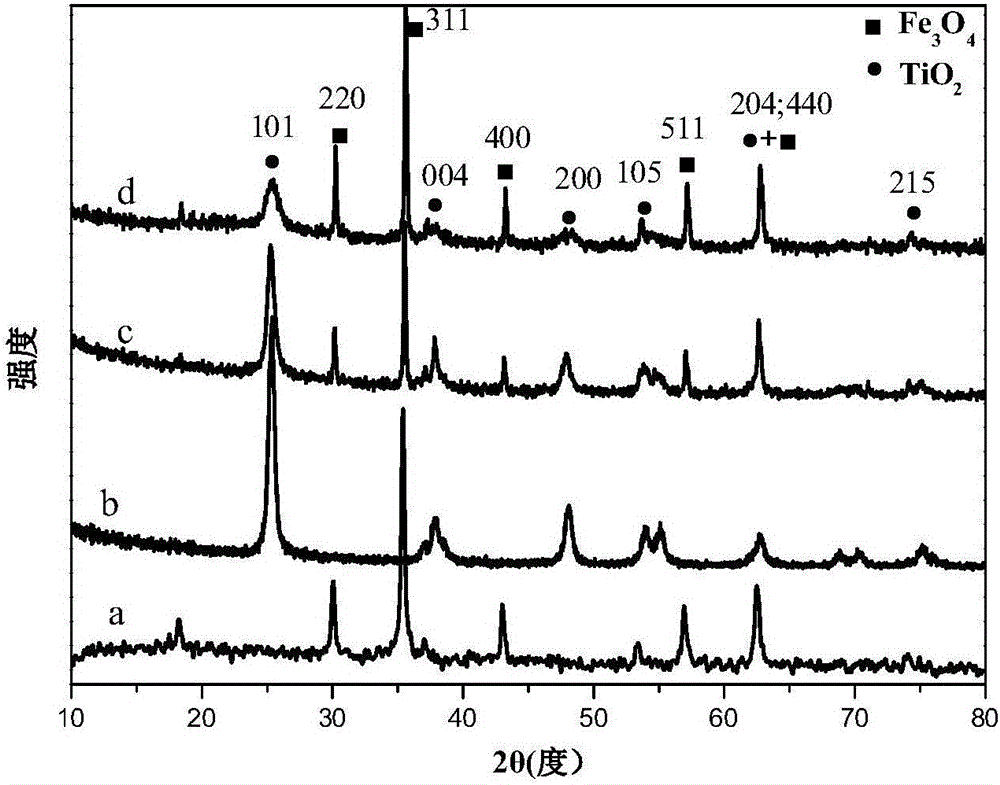

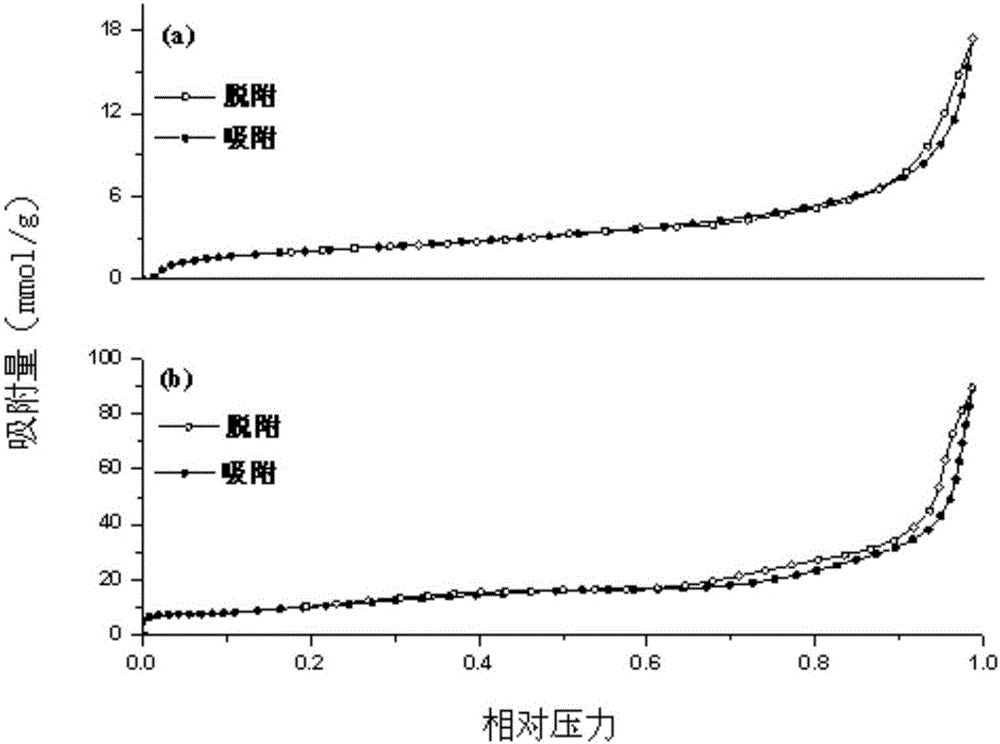

[0032] (1) Dissolve 0.5g of nanometer iron ferric oxide in 50ml of isopropanol, ultrasonically disperse for 30 minutes to obtain solution A, then add 0.5ml of aminopropyltrimethoxysilane to obtain solution B, and heat solution B to reflux at 80°C 24h. The reaction product was washed with absolute ethanol and distilled water, and then vacuum-dried at 60°C to obtain aminated nano-ferric oxide;

[0033] (2) Add the aminated nanometer iron ferric oxide prepared by 0.1g step (1) into 100mL isopropanol, and ultrasonically disperse to obtain solution C; Graphene oxide is added to water for ultrasonic dispersion, and the concentration of 150mL graphene oxide is obtained as 0.5g / L solution D; then add C dropwise to D under the condition of mechanical stirring, stir and react for 3h, the reaction product is washed with absolute ethanol and distilled water, and then vacuum-dried at 60°C to obtain Fe 3 o 4 / GO composites;

[0034] (3) Fe prepared by 30mg step (2) 3 o 4The / GO composi...

Embodiment 2

[0037] (1) Dissolve 0.75g of nanometer iron ferric oxide in 50ml of isopropanol, and disperse it ultrasonically for 30 minutes to obtain solution A, then add 0.5ml of aminopropyltrimethoxysilane to obtain solution B, which is heated to reflux at 80°C 20h. The reaction product was washed with absolute ethanol and distilled water, and then vacuum-dried at 60°C to obtain aminated nano-ferric oxide;

[0038] (2) Add the aminated nano-ferric oxide ferric oxide prepared by 0.15g step (1) into 100mL isopropanol, and ultrasonically disperse to obtain solution C; Graphene oxide is added to water for ultrasonic dispersion, and the concentration of 150mL graphene oxide is obtained as 0.5g / L solution D; then add C dropwise to D under the condition of mechanical stirring, stir the reaction for 2h, wash the reaction product with absolute ethanol and distilled water, and then dry it in vacuum at 80°C to obtain Fe 3 o 4 / GO composites;

[0039] (3) Fe prepared by 30mg step (2) 3 o 4 The ...

Embodiment 3

[0042] (1) Dissolve 0.5g of nanometer iron ferric oxide in 50ml of isopropanol, ultrasonically disperse for 30 minutes to obtain solution A, then add 0.5ml of aminopropyltrimethoxysilane to obtain solution B, and heat solution B to reflux at 80°C 24h. The reaction product was washed with absolute ethanol and distilled water, and then vacuum-dried at 60°C to obtain aminated nano-ferric oxide;

[0043] (2) Add the aminated nanometer iron ferric oxide prepared by 0.1g step (1) into 100mL isopropanol, and ultrasonically disperse to obtain solution C; Graphene oxide is added to water for ultrasonic dispersion, and the concentration of 100mL graphene oxide is obtained as 1.0g / L solution D; then add C dropwise to D under mechanical stirring conditions, stir for 3h, the reaction product is washed with absolute ethanol and distilled water, and then vacuum-dried at 70°C to obtain Fe 3 o 4 / GO composites;

[0044] (3) Fe prepared by 30mg step (2) 3 o 4 The / GO composite material was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com