Metal-matrix composite and preparation method thereof

A composite material and metal-based technology, applied in the field of materials, can solve problems such as poor wear resistance, poor bonding strength, and large surface friction, and achieve the effects of reducing production costs, high production efficiency, and short production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The composition and preparation steps of the metal matrix composite material in this embodiment are as follows:

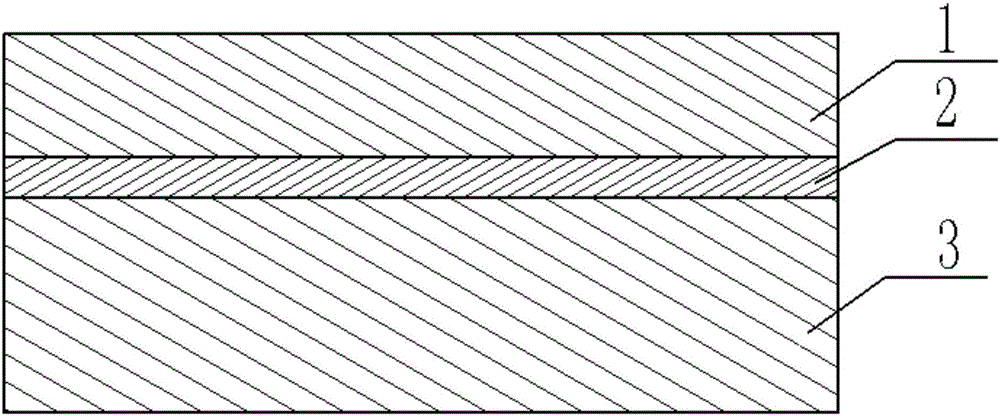

[0029] a) The material of the metal base 3 is 45# steel. First, the metal base 3 is ultrasonically cleaned for 15 minutes. After the ultrasonic cleaning is completed, the metal base 3 is dried in a vacuum dryer, and the temperature of the dryer is set to 80 ℃, the time is 0.5 hours, sandblasting is carried out after drying, the sandblasting particle size is 20 mesh quartz sand, the sandblasting pressure is 0.8MPa, the sandblasting time is 5s, and the metal substrate 3 is cleaned with deionized water after sandblasting 5 times, after washing, put the metal base 3 into the mixture of concentrated sulfuric acid and water and soak for 5 minutes, wherein the specific gravity of concentrated sulfuric acid and water is 1:1, then wash the metal base 3 with deionized water 5 times, after washing, the metal The substrate 3 is dried in a vacuum dryer, the temperature o...

Embodiment 2

[0035] The composition and preparation steps of the metal matrix composite material in this embodiment are as follows:

[0036]a) The material of the metal base 3 is 45# steel. First, the metal base 3 is ultrasonically cleaned for 17 min. ℃, the time is 0.5 hours, sandblasting is carried out after drying, the sandblasting particle size is 50 mesh quartz sand, the sandblasting pressure is 0.8MPa, the sandblasting time is 7s, and the metal substrate 3 is cleaned with deionized water after sandblasting 5 times, after washing, put the metal base 3 into the mixed solution of concentrated sulfuric acid and water and soak for 8 minutes, wherein the specific gravity of concentrated sulfuric acid and water is 1:1, then wash the metal base 3 with deionized water 5 times, after washing, the metal The substrate 3 is dried in a vacuum dryer, the temperature of the dryer is set at 80° C., and the time is 1 hour;

[0037] b) The mass percentages of the components of the middle bonding layer...

Embodiment 3

[0042] The composition and preparation steps of the metal matrix composite material in this embodiment are as follows:

[0043] a) The material of the metal base 3 is 45# steel. First, the metal base 3 is ultrasonically cleaned for 20 minutes. After the ultrasonic cleaning is completed, the metal base 3 is dried in a vacuum dryer, and the temperature of the dryer is set to 80 ℃, the time is 0.5 hours, sandblasting is carried out after drying, the sandblasting particle size is 80 mesh quartz sand, the sandblasting pressure is 0.8MPa, the sandblasting time is 10s, and the metal substrate 3 is cleaned with deionized water after sandblasting 5 times, after washing, put the metal substrate 3 into the mixture of concentrated sulfuric acid and water and soak for 10 minutes, wherein the specific gravity of concentrated sulfuric acid and water is 1:1, then wash the metal substrate 3 with deionized water for 5 times, and wash the metal substrate 3 after washing. The substrate 3 is dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com