Underwater reinforced concrete grouting cement and preparation method thereof

A technology of parts by weight and phenalkamine curing agent, which is applied in the direction of adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problem that epoxy adhesives cannot meet structural reinforcement, underwater bonding strength is reduced, and cannot be completely Underwater curing and other problems, to achieve excellent reactivity, high fluidity, and save the amount of glue used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] An underwater steel glue, including A component and B component, the parts by weight of the A component are: epoxy resin 128: 75 parts, reactive diluent: 10 parts and silane coupling agent: 0.5 parts , The parts by weight of the B component are: cashew nut oil modified phenalkamine curing agent: 90 parts.

[0015] Its preparation method comprises the following steps:

[0016] S1: Mixing: put epoxy resin 128, reactive diluent and silane coupling agent into a magnetic stirrer, stir at 400r / min for 10min, the temperature is 10 degrees Celsius, and it is ventilated;

[0017] S2: Combination: Add the cashew nut oil modified phenalkamine curing agent to the mixture in step S2 at a ratio of 1:2, mix evenly, and use it immediately after mixing.

Embodiment 2

[0019] An underwater steel glue, including A component and B component, the parts by weight of the A component are: epoxy resin 128: 85 parts, reactive diluent: 15 parts and silane coupling agent: 1.5 parts , The parts by weight of the B component are: cashew nut oil modified phenalkamine curing agent: 110 parts.

[0020] Its preparation method comprises the following steps:

[0021] S1: Mixing: put epoxy resin 128, reactive diluent and silane coupling agent into a magnetic stirrer, stir at 1000r / min for 20min, the temperature is 25 degrees Celsius, and it is ventilated;

[0022] S2: Combination: Add the cashew nut oil modified phenalkamine curing agent to the mixture in step S2 at a ratio of 1:2, mix evenly, and use it immediately after mixing.

Embodiment 3

[0024] An underwater steel glue, comprising A component and B component, the parts by weight of the A component are: epoxy resin 128: 80 parts, reactive diluent: 13 parts and silane coupling agent: 1 part , The parts by weight of the B component are: cashew nut oil modified phenalkamine curing agent: 100 parts.

[0025] Its preparation method comprises the following steps:

[0026] S1: Mixing: Put epoxy resin 128, reactive diluent and silane coupling agent into a magnetic stirrer, stir at 700r / min for 15min, the temperature is 18 degrees Celsius, and it is ventilated;

[0027] S2: Combination: Add the cashew nut oil modified phenalkamine curing agent to the mixture in step S2 at a ratio of 1:2, mix evenly, and use it immediately after mixing.

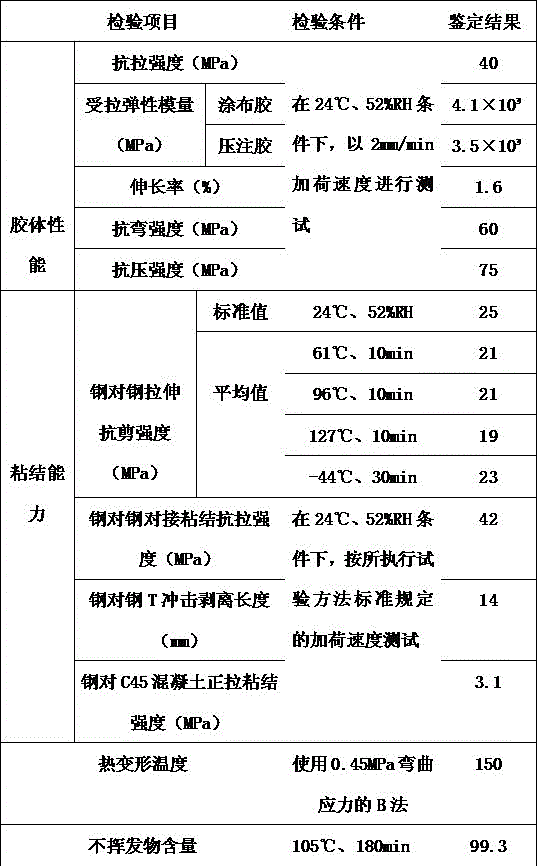

[0028] After curing for 7 days, test its performance. The performance is as follows:

[0029]

[0030] After comparing with the relevant requirements of Table 4.4.2-1 in GB 50728-2011, all are qualified.

[0031] In the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com