Methanol fuel additive for diesel engines

A methanol fuel and diesel engine technology, applied in fuel additives, fuel, liquid carbon-containing fuel, etc., can solve the problems of methanol fuel low power performance, carbon deposition, high raw material cost, etc., to improve storage stability, avoid wear and damage, The effect of good combustion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

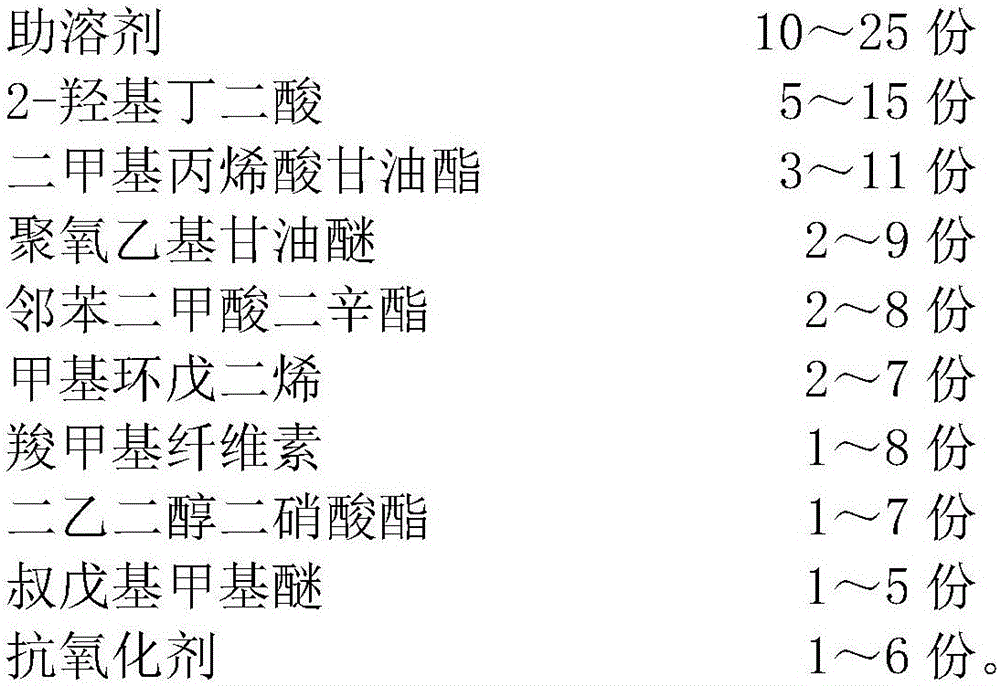

[0033] The methanol fuel additive for diesel engines is made of the following raw materials in parts by weight (mixed uniformly at room temperature):

[0034]

[0035] The above-mentioned auxiliary solvent is a mixture of 5 parts by weight of xylene, 5 parts by weight of amyl alcohol and 30 parts by weight of n-hexaneazole.

[0036] The above antioxidant is a mixture of 10 parts by weight of cresol diphenyl phosphate, 25 parts by weight of 2,6-di-tert-butyl-p-cresol and 5 parts by weight of 4-methoxy o-phenylenediamine.

[0037] When the methanol fuel is prepared, the added amount of the additive is 0.2% of the mass of the methanol fuel.

Embodiment 2

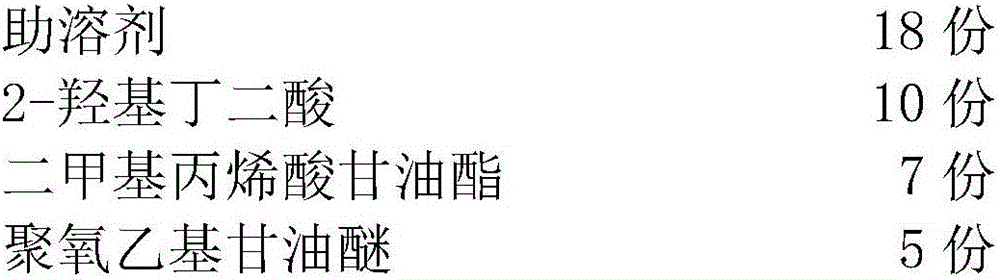

[0039] The methanol fuel additive for diesel engines is made of the following raw materials in parts by weight (mixed uniformly at room temperature):

[0040]

[0041] The aforementioned auxiliary solvent is a mixture of 8 parts by weight of xylene, 7 parts by weight of amyl alcohol and 27 parts by weight of n-hexaneazole.

[0042] The above antioxidant is a mixture of 12 parts by weight of cresol diphenyl phosphate, 23 parts by weight of 2,6-di-tert-butyl-p-cresol and 8 parts by weight of 4-methoxy o-phenylenediamine.

[0043] When the methanol fuel is prepared, the added amount of the additive is 0.3% of the mass of the methanol fuel.

Embodiment 3

[0045] The methanol fuel additive for diesel engines is made of the following raw materials in parts by weight (mixed uniformly at room temperature):

[0046]

[0047] The aforementioned auxiliary solvent is a mixture of 10 parts by weight of xylene, 10 parts by weight of amyl alcohol and 25 parts by weight of n-hexaneazole.

[0048] The above antioxidant is a mixture of 15 parts by weight of cresol diphenyl phosphate, 20 parts by weight of 2,6-di-tert-butyl-p-cresol and 10 parts by weight of 4-methoxy o-phenylenediamine.

[0049] When the methanol fuel is prepared, the added amount of the additive is 0.4% of the mass of the methanol fuel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com