A stainless steel slag wet treatment process method and device

A process method and technology of a process device are applied in the field of stainless steel slag treatment process methods and devices, which can solve the problems of low metal yield and high construction and operation costs, and achieve improved metal yield, resource utilization, and efficient recovery. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

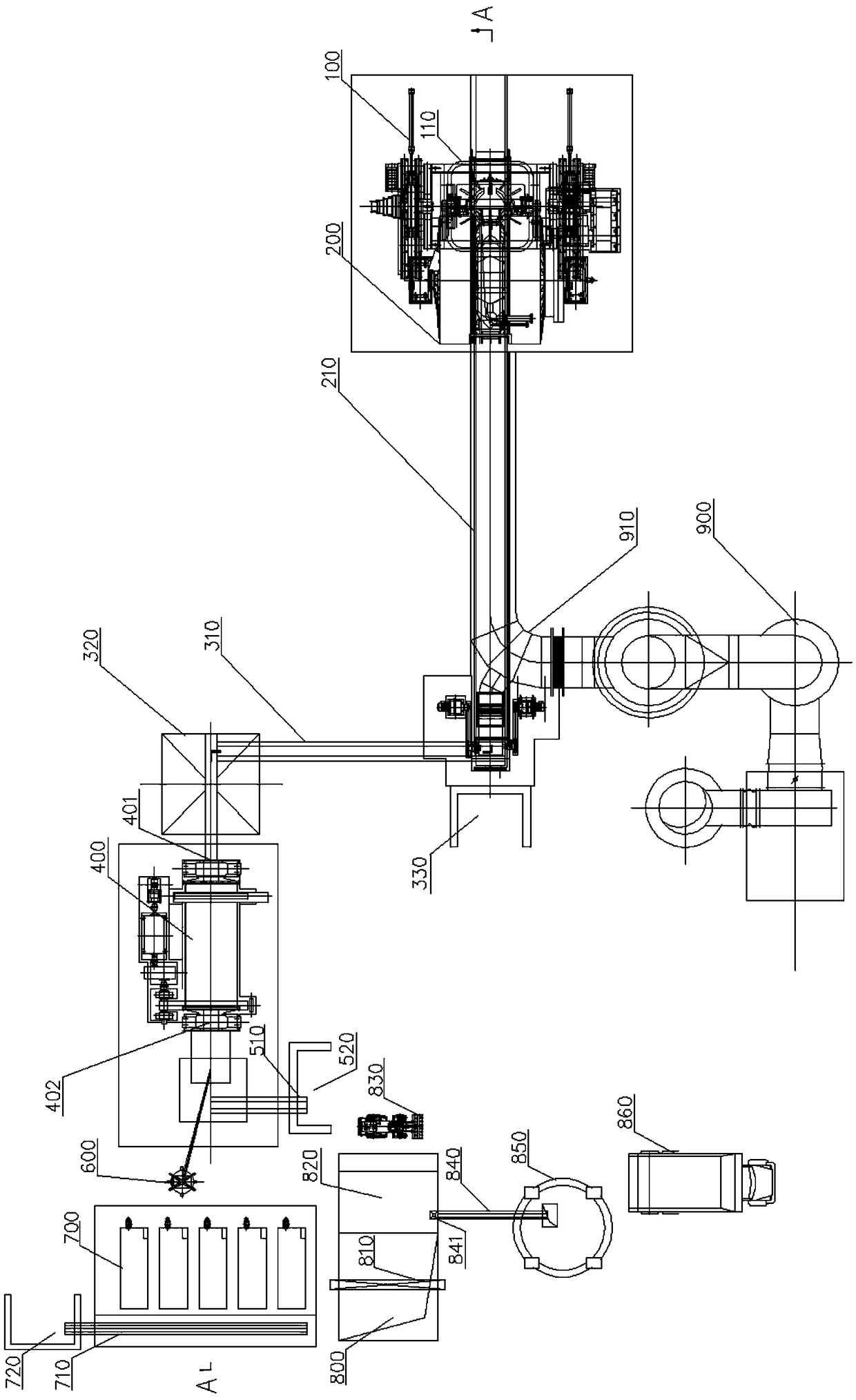

[0045] The present invention will now be further explained in conjunction with the drawings.

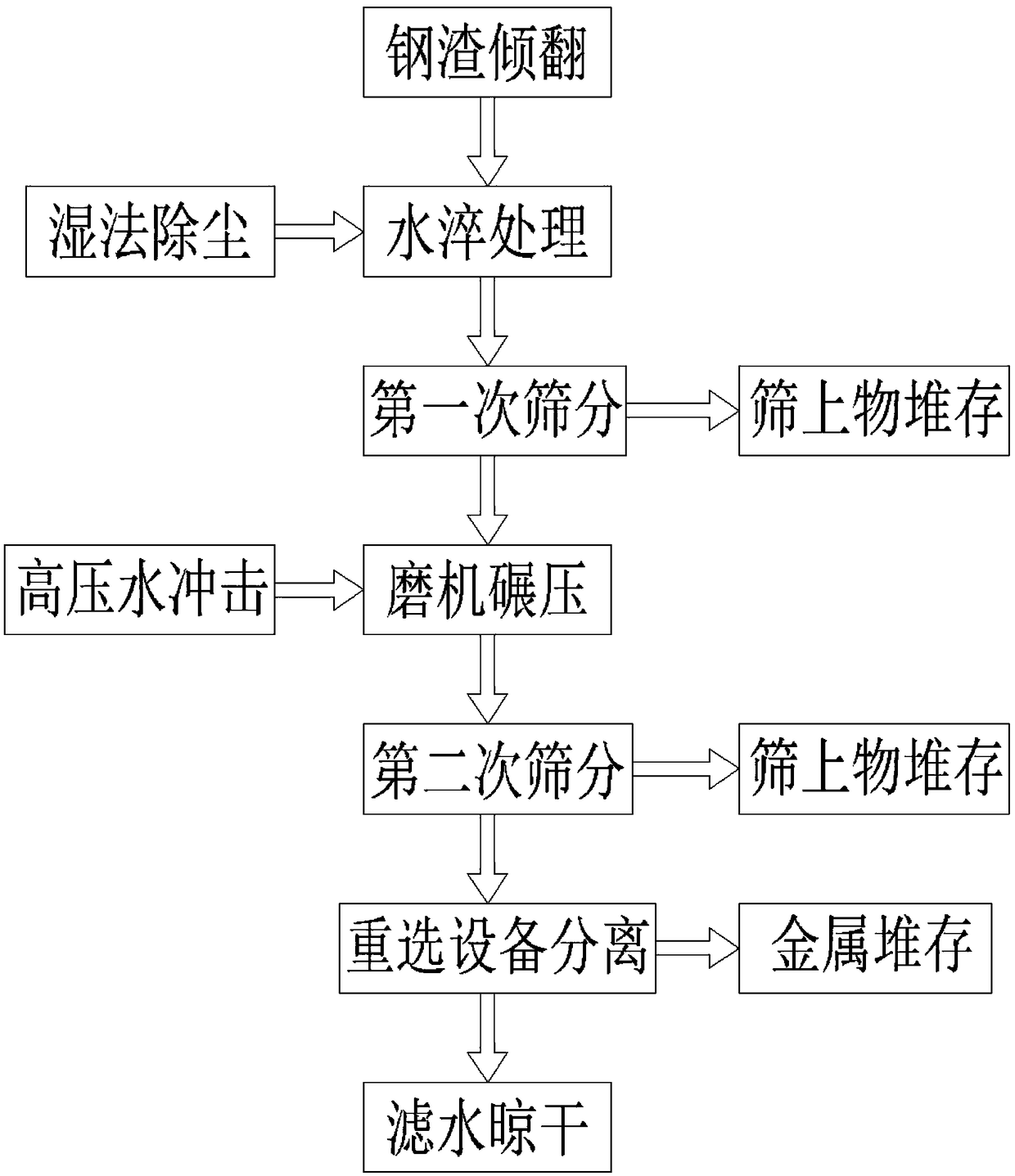

[0046] figure 2 It is the process flow chart of the wet treatment process of stainless steel slag according to the present invention. Such as figure 2 As shown, the stainless steel slag wet treatment process method of the present invention includes the following steps:

[0047] (1) Turn over the steel slag in the slag tank;

[0048] (2) Water quenching of the dumped steel slag;

[0049] (3) After the water quenching treatment, the steel slag with a particle size of 0~150mm is subjected to the first screening treatment;

[0050] (4) Stack the oversize material (steel slag with a particle size of 70-150mm) from the first screening. The undersize material for the first screening is steel slag with a particle size of less than 70mm. Downstream into the mill for crushing;

[0051] (5) Perform a second screening treatment on the steel slag crushed by the mill;

[0052] (6) The oversize material of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com