Heat insulation cover for engine exhaust pipe and processing technology

A technology for heat insulation and exhaust pipes, which is applied to engine components, machines/engines, exhaust devices, etc., can solve problems such as unsatisfactory heat insulation effects of pipes, increase effective contact area, reduce production costs, and improve thermal conductivity low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

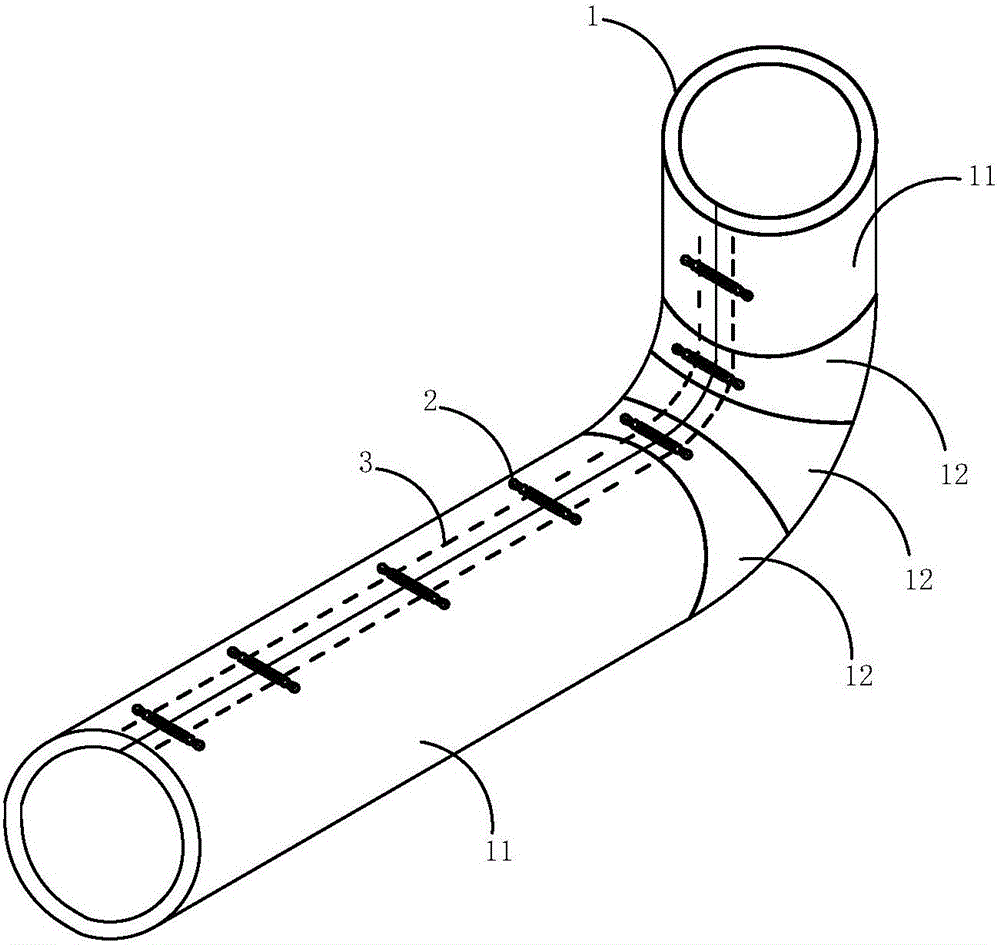

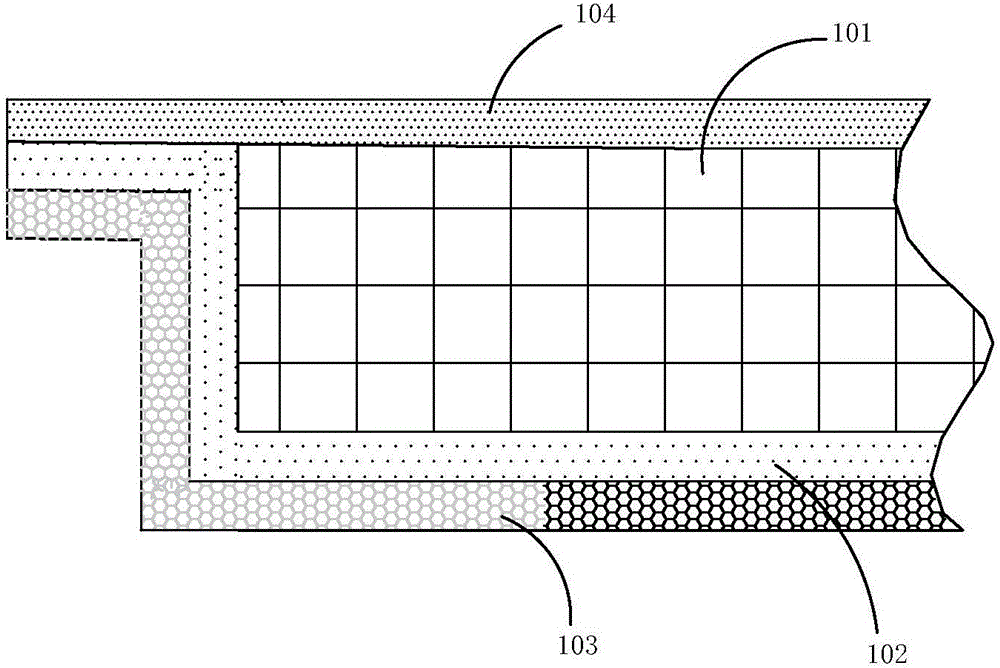

[0024] see figure 1 The present invention is an engine exhaust pipe heat insulation cover, which includes a heat insulation body 1 and a fastening device 2; the heat insulation body 1 includes a straight pipe part 11 and an elbow part 12 and is a multi-layer structure, including a middle heat insulation layer 101 , inner heat preservation layer 102, inner protection net 103, outer heat preservation layer 104 and outer protection net (not identified).

[0025] In this embodiment, the elbow portion 12 and the straight pipe portion 11 are divided into five sections along the direction of the exhaust pipe; they are sewn to form a package shape divided along the axis, and after being wrapped on the exhaust pipe, they are fastened The device 2 forms a thermal insulation structure fastened on the outside of the exhaust pipe and closely attached to the exhaust pipe.

[0026] In this embodiment, the middle heat insulation layer 101 adopts nano-silica airgel felt. The inner insulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com