A Heterodyne 2/3D Grating Displacement Coarse/Fine Measuring System

A three-dimensional grating and fine measurement technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of unrealizable, low resolution, waste of system resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

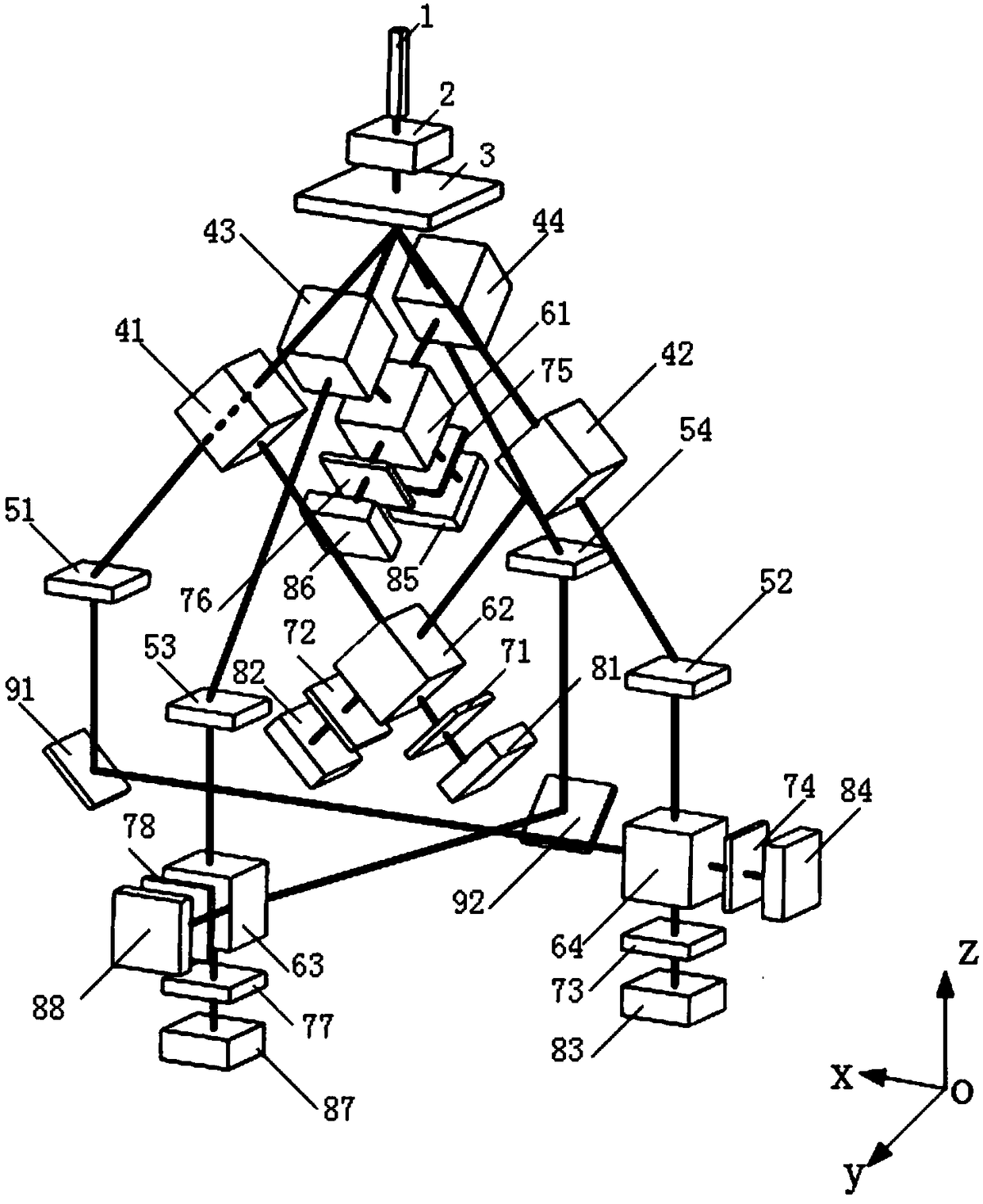

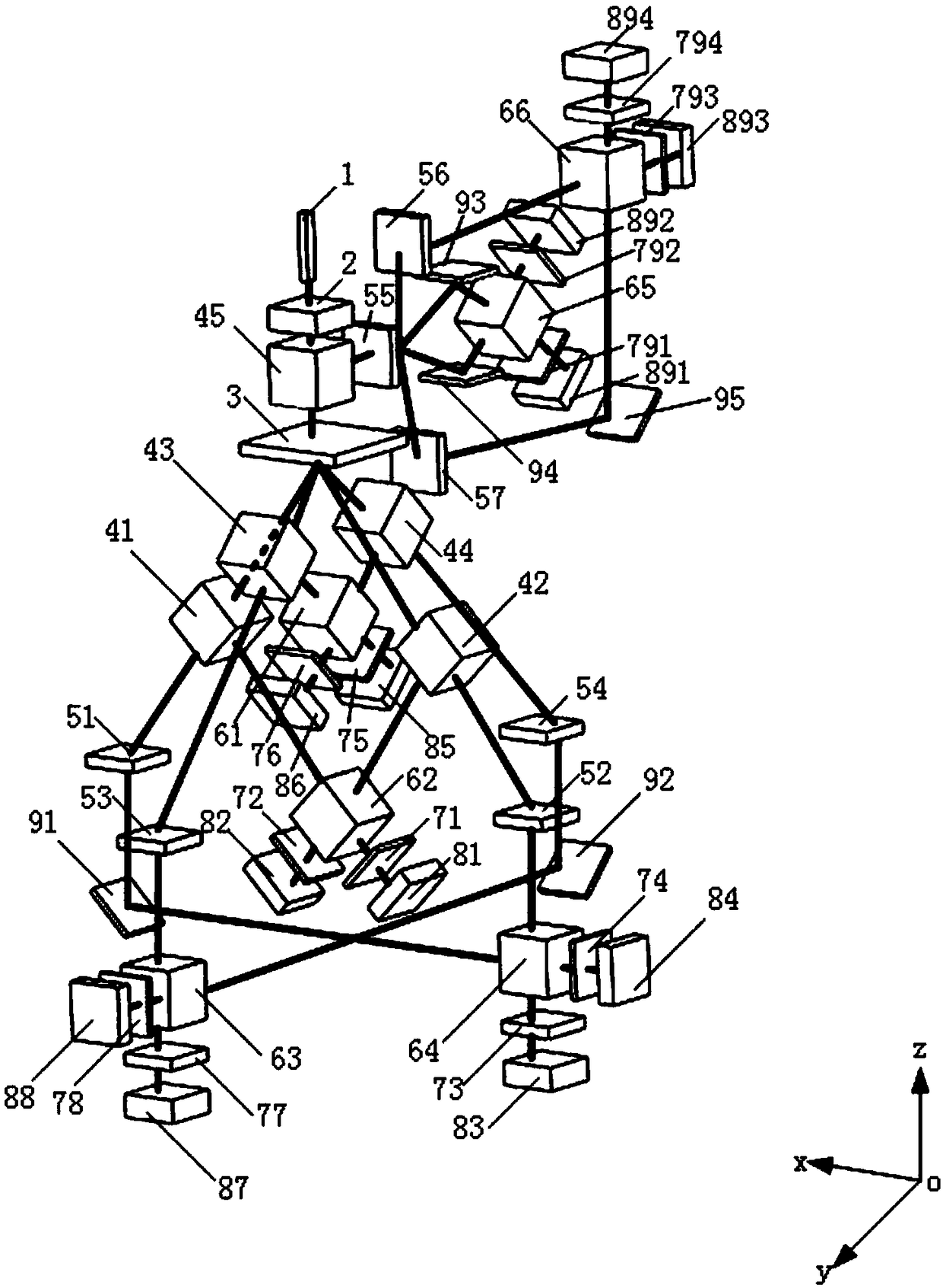

[0020] figure 1 Shown is the two-dimensional grating displacement coarse / fine measuring part of the present invention, which includes a single-frequency laser light source 1; an electro-optical modulator 2; a two-dimensional transmission measuring grating 3; a first beam splitting prism 41; a second beam splitting prism 42; Three dichroic prism 43; fourth dichroic prism 44; first one-dimensional transmission measurement grating 51; second one-dimensional transmission measurement grating 52; third one-dimensional transmission measurement grating 53; fourth one-dimensional transmission measurement grating 54 ; the first polarizing beam splitting prism 61; the second polarizing beam splitting prism 62; the third polarizing beam splitting prism 63; the fourth polarizing beam splitting prism 64; the first polarizing plate 71; the second polarizing plate 72; the third polarizing plate 73; the fourth polarizing plate plate 74; fifth polarizer 75; sixth polarizer 76; seventh polarizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com