Experimental Simulation Platform and Experimental Method for Tunnel Lining Structure Crack Treatment

一种实验模拟、衬砌的技术,应用在仪器、测量装置、科学仪器等方向,能够解决修补材料价格昂贵、不适合推广等问题,达到确保可靠性、更换方便、保证准确性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

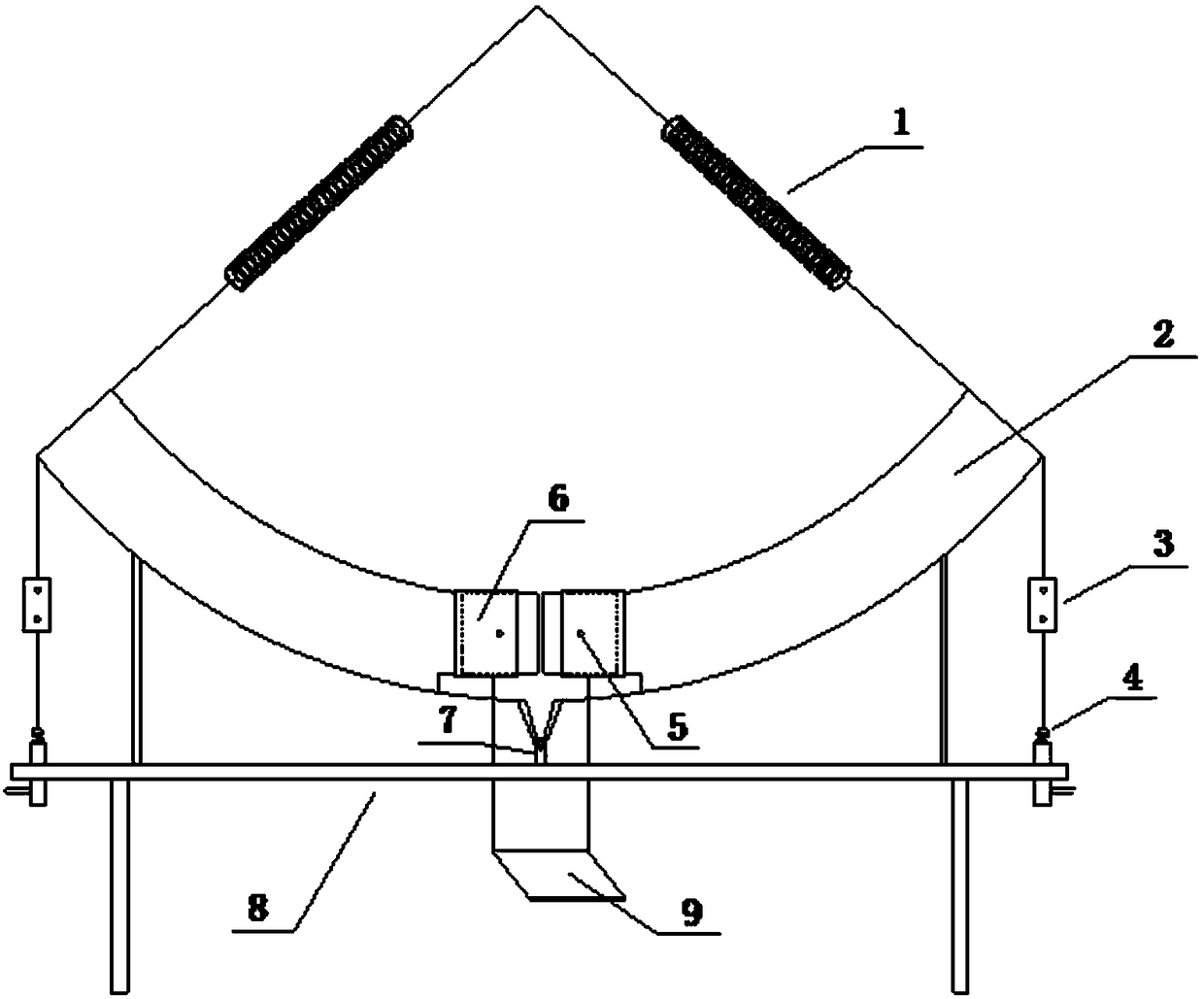

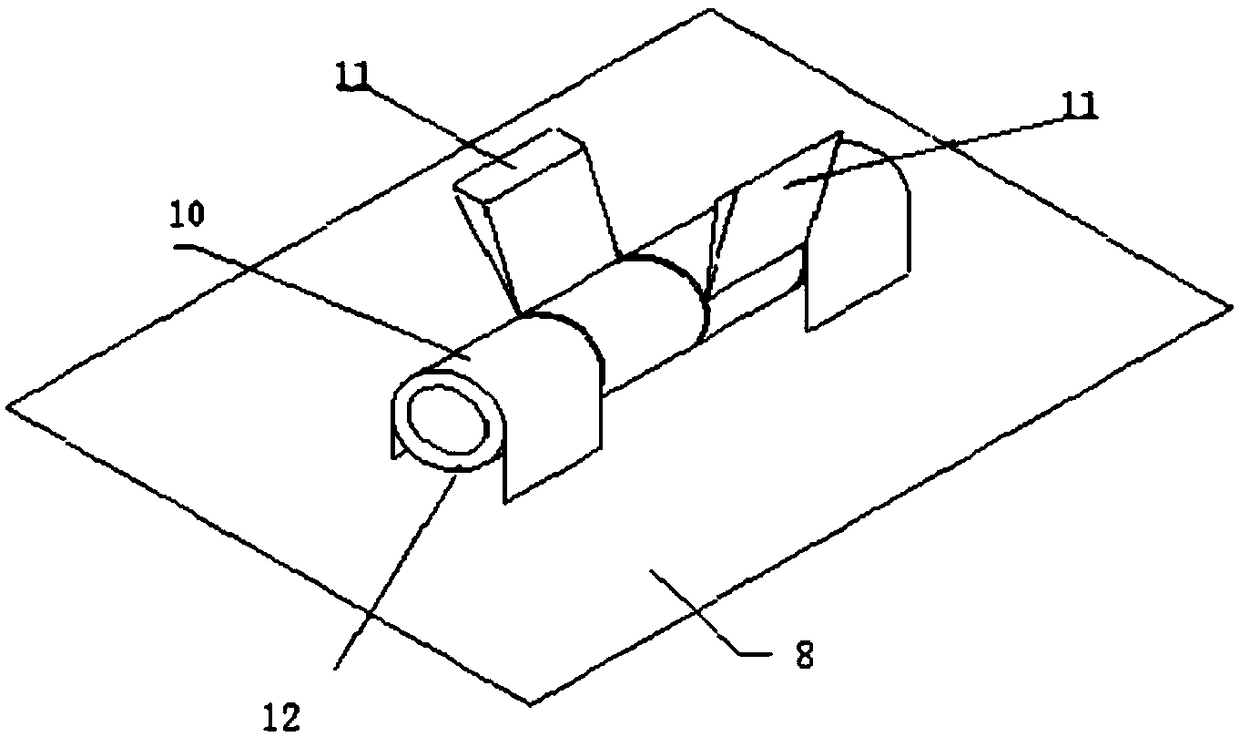

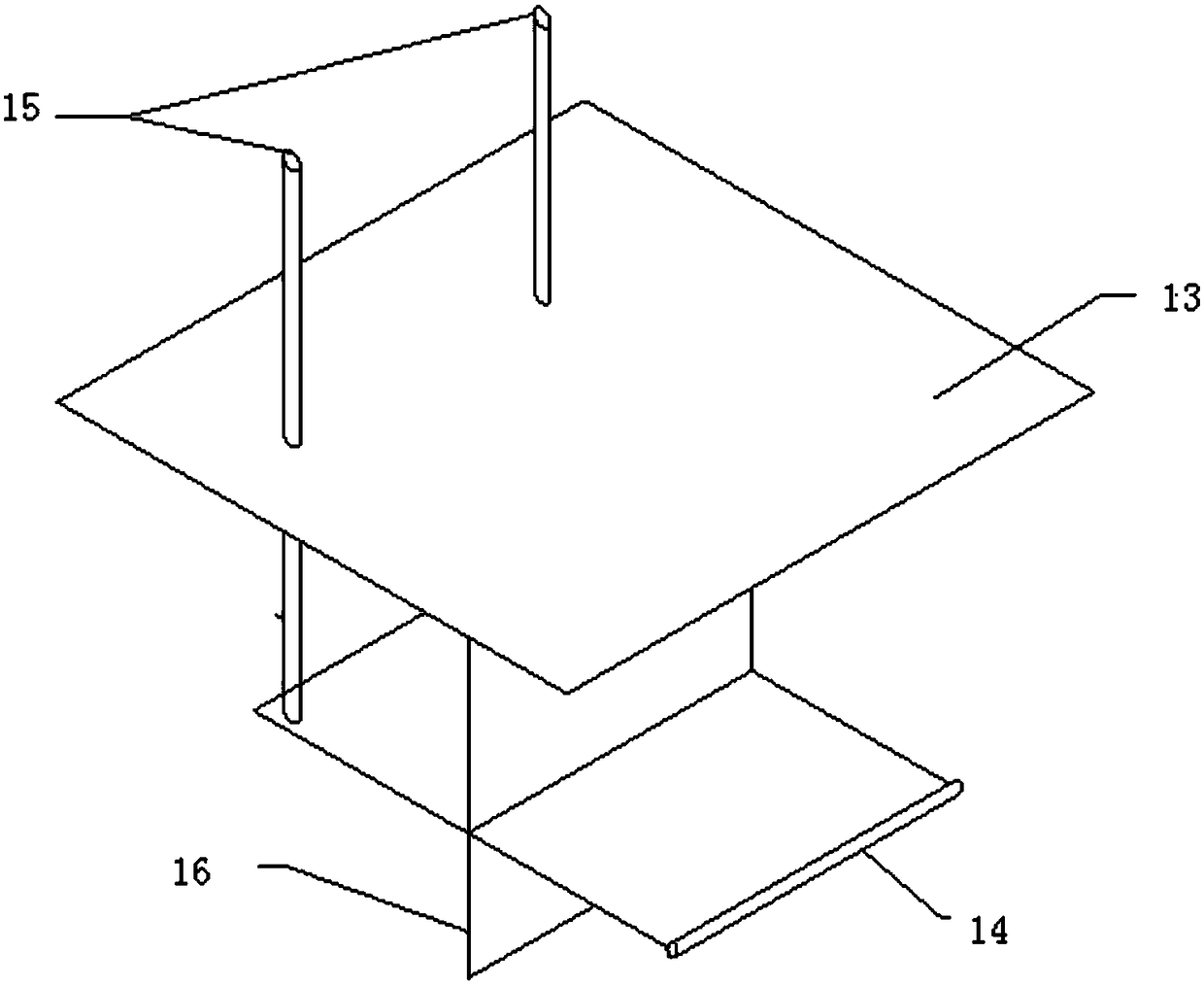

[0033] The present invention provides an experimental simulation platform for treating cracks in tunnel lining structures, including a test bench, a displacement gauge, two independent arc-shaped steel channels 2, and a hinge support 7 installed on the test bench. The cross-section of the arc-shaped steel groove 2 is rectangular; the lower surface of two ends of the arc-shaped steel groove 2 is connected with the hinge support 7 and the two arc-shaped steel grooves 2 jointly form an arc-shaped workpiece; The other ends of the arc-shaped steel channels are connected to the test bench through support rods and are hinged between the support rods and the arc-shaped steel channels; a force loading device 4 is arranged below the other ends of the two arc-shaped steel channels, and the arc-shaped steel frame and the Tensile dynamometers 3 are arranged between the corresponding force loading devices 4; specimen fixing devices 5 are provided at the ends of the two arc-shaped steel groov...

Embodiment 2

[0045] This embodiment provides an experimental method for diagnosing cracks in tunnel lining structures, including the following steps:

[0046] Step 1: Prepare test pieces with cracks of different specifications, the specific specifications are: the crack sizes are 0.5㎜, 1㎜, 2㎜, 5㎜, 10㎜, 20㎜;

[0047] Step 2: Install the test piece, continue to load, simulate the continuous cracking of the cracked test piece, and record the cracking degree, crack displacement and loading force under different stress conditions in real time;

[0048] Step 3: Replace the cracked specimens of different specifications, and implement steps 1 and 2;

[0049] Step 4: Based on the data obtained in Step 1, Step 2 and Step 3, summarize the crack cracking time, crack size and loading force of crack specimens of different specifications during the continuous stress process and under different loading forces. relationship between sizes.

Embodiment 3

[0051] This embodiment provides an experimental method for treating cracks in tunnel lining structures, including the following steps:

[0052] Step 1: Select test pieces with various crack specifications in turn; install the test pieces on the test bench; the crack specifications are 1mm, 2㎜, 5㎜, 10㎜ or 20㎜.

[0053] Step 2: Deploy the repair material; the repair material is a polymer-based gel, which is prepared according to the following material and weight ratio: fly ash: metakaolin: composite activator: Portland cement: silica fume = 14:65:10 :10:1; wherein the composite activator slurry is prepared according to the following material and weight ratio: instant sodium silicate: sodium hydroxide: nano silicon dioxide = 8:1:1.

[0054] Step 3: Simulate the treatment experiment of lining cracks under different water seepage. The specific steps are: debug the water seepage at 250 ml, 500 ml, and 800 ml per minute respectively. For initial setting, load the tensile force to 1k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com