Holographic reflective array compact range

A reflective array and compact field technology, applied in antenna radiation patterns, radio wave measurement systems, instruments, etc., can solve difficult manufacturing costs and other problems, and achieve the effect of simple manufacture, light structure, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

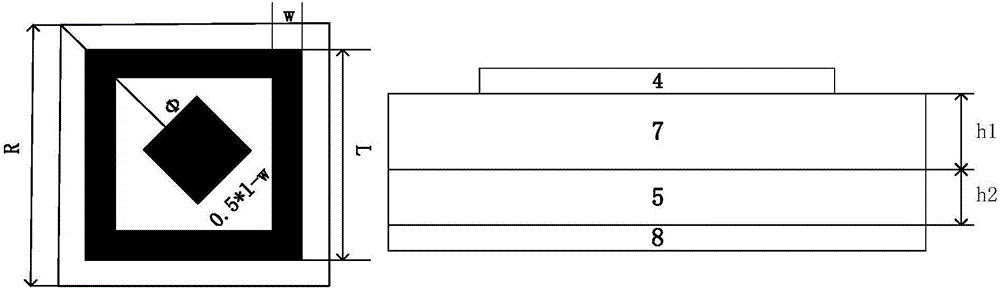

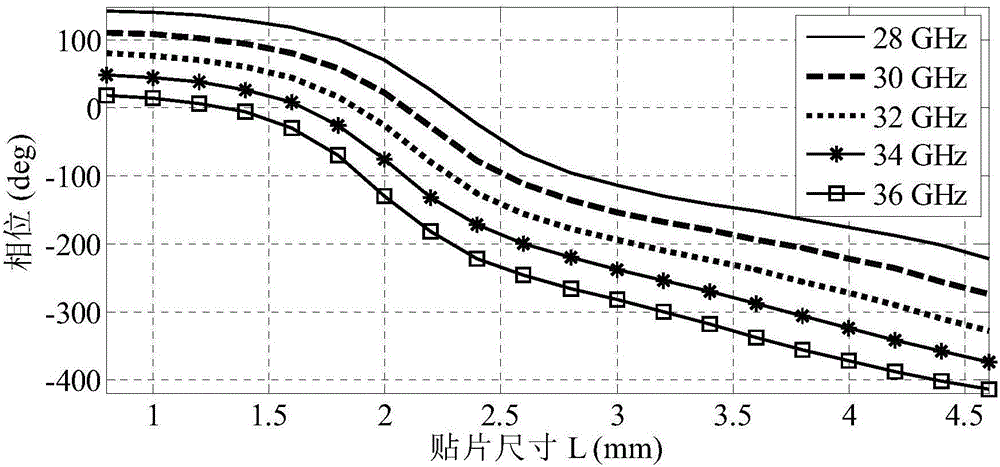

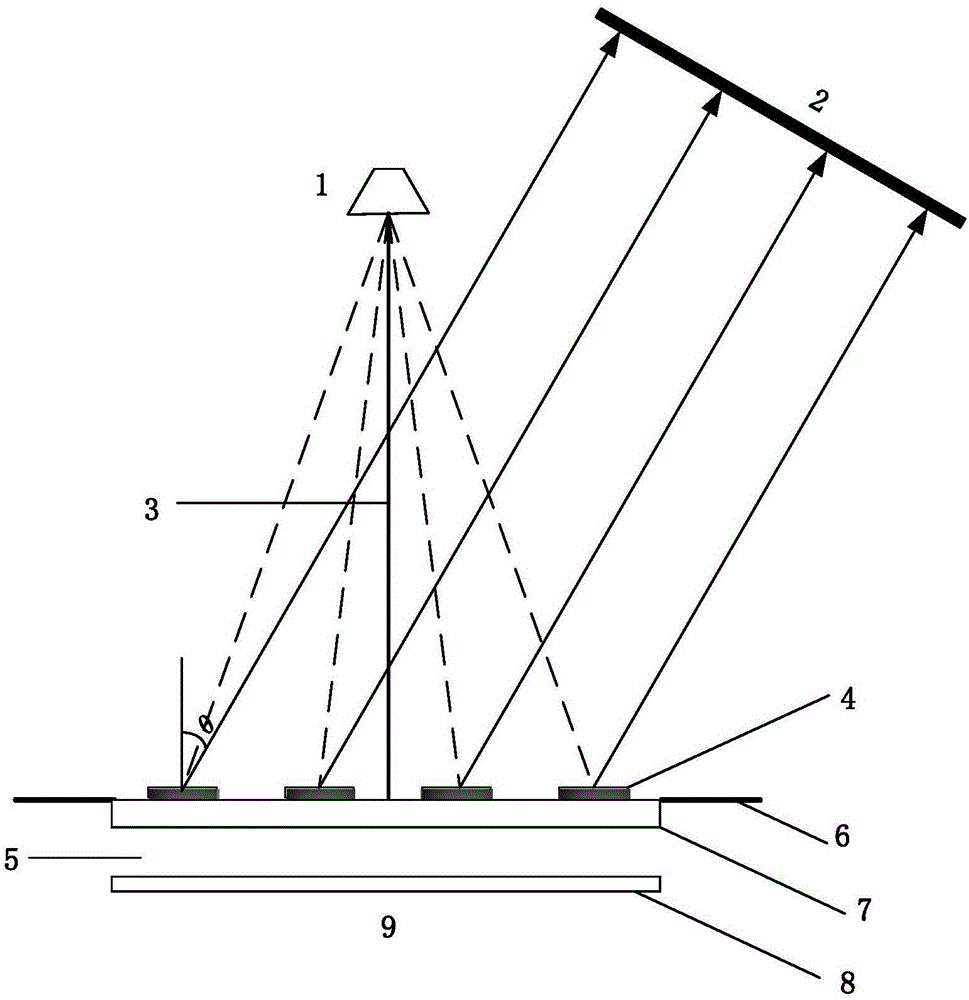

[0023] Such as image 3 As shown, the reflectarray antenna 9 is composed of a reflectarray unit 4, a dielectric substrate 7, an air layer 5, and a ground plate 8. Reflector units 4 of different sizes have different abilities to adjust the phase of electromagnetic waves. The manufacture of the reflectarray antenna 9 It can be manufactured using a PCB process.

[0024] The function of the reflectarray antenna 9 is to correct the spherical wave emitted by the feed source into a plane wave at a short distance.

[0025] The feed source 1 feeds forward and vertically irradiates the reflectarray antenna 9 to ensure that the aperture is uniformly irradiated, and the spherical wave approximately vertically irradiates all the reflectarray units 4 .

[0026] The narrow field focal length 3 of the holographic reflectarray is set to 1.5 times the side l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com