Graphene electric heating plate for ground heating and production method thereof

A technology of graphene and electric heating plate, which is applied in the field of floor heating construction engineering, can solve the problems of lack of thermal stability of electric heating plate, large temperature difference on the surface of electric heating plate, small adhesion of electric heating layer, etc., and achieve excellent thermal conductivity and electrical conductivity, and stable thermal power , good heat fusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

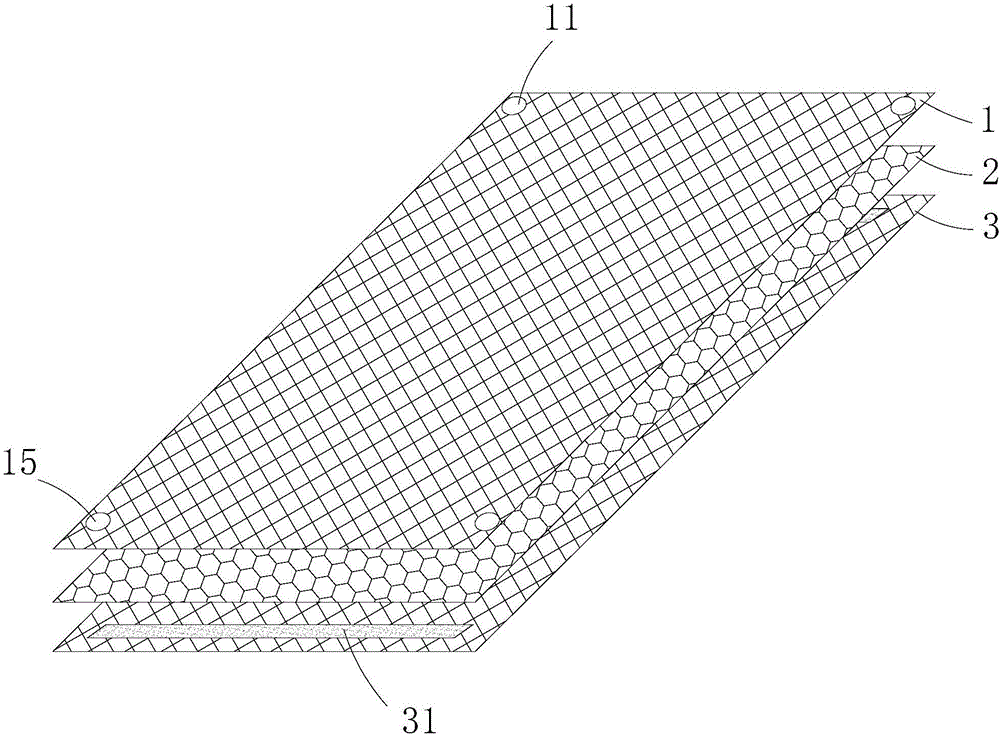

[0020] Such as figure 1 As shown, the present embodiment provides a graphene electric heating plate for floor heating, which is mainly composed of an upper epoxy resin sheet 1, a graphene heating layer 2 and a lower epoxy resin sheet 3 stacked in sequence, and the lower epoxy resin sheet The front and rear ends of 3 are respectively provided with a second metal sheet 31, the second metal sheet 31 is located on the surface of the lower epoxy resin sheet 3 close to the graphene heating layer 2, and the upper epoxy resin sheet 1 The front and rear ends are respectively provided with a front wire hole 11 and a rear wire hole 15, and the wire hole 11 is pierced with an electric wire electrically connected to the second metal sheet 31 at the front end of the lower epoxy resin sheet 3, and the rear wire hole 15 is pierced with electric wires electrically connected to the second metal sheet 31 at the rear end of the lower epoxy resin sheet 3 .

Embodiment 2

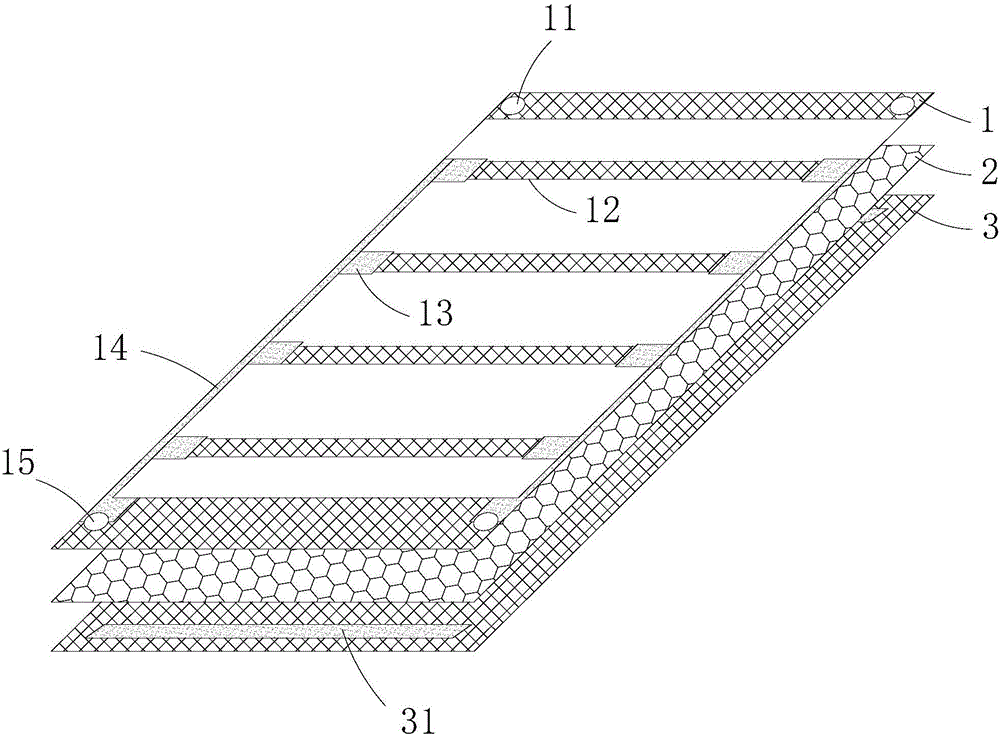

[0022] Such as figure 2 As shown, the present embodiment provides a graphene electric heating plate for floor heating, which is mainly composed of an upper epoxy resin sheet 1, a graphene heating layer 2 and a lower epoxy resin sheet 3 stacked in sequence, and the lower epoxy resin sheet The front and rear ends of 3 are respectively provided with a second metal sheet 31, the second metal sheet 31 is located on the surface of the lower epoxy resin sheet 3 close to the graphene heating layer 2, and the upper epoxy resin sheet 1 The front and rear ends are respectively provided with a front wire hole 11 and a rear wire hole 15, and the wire hole 11 is pierced with an electric wire electrically connected to the second metal sheet 31 at the front end of the lower epoxy resin sheet 3, and the rear wire hole 15 is pierced with electric wires electrically connected to the second metal sheet 31 at the rear end of the lower epoxy resin sheet 3 . The upper epoxy resin sheet 1 is mainly...

Embodiment 3

[0030] This embodiment specifically provides a method for producing a graphene electric heating plate for floor heating described in the foregoing embodiments 1 and 2. The steps are as follows: Weigh 15 parts by weight of graphene, 35 parts by weight of carbon black, and 30 parts by weight of polymer Resin, the graphite of 18 parts by weight, the diethylene glycol butyl ether of 12 parts by weight and the graphene dispersant of 8 parts by weight (in another improved example to present embodiment 3, select carbon black dispersant to replace present embodiment 3 The graphene dispersant in the mixture) is mixed and prepared to obtain the graphene fluid body. Make the lower layer epoxy resin sheet 3 and the upper layer epoxy resin sheet 1 respectively according to the required shape and structure. Use screen printing to print the graphene fluid on the upper surface of the lower epoxy resin sheet 3, heat up to 180°C to dry the graphene fluid to form the graphene heating layer 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com