Transient state experiment device and method for catalyst high temperature and high pressure evaluation

An experimental device, high temperature and high pressure technology, applied in chemical instruments and methods, chemical analysis by catalysis, chemical/physical processes, etc., can solve problems such as transient inaccuracy, achieve fast heating and cooling rates, low surface temperature, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

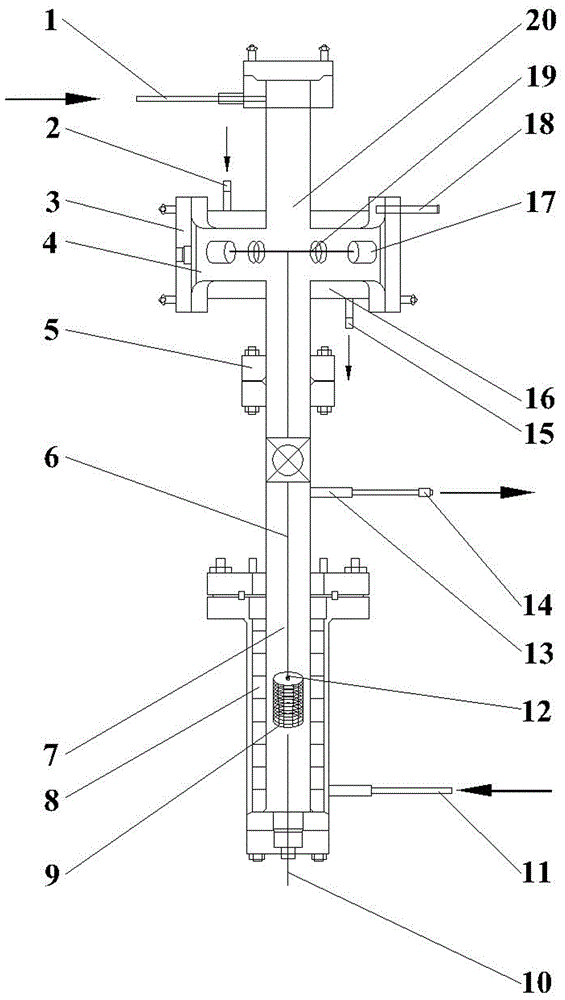

[0033] The structure of the catalyst high temperature and high pressure transient test evaluation device is as follows: figure 1 As shown, it has a reaction shell made of temperature-resistant and pressure-resistant chromium-molybdenum heat-resistant steel. The reaction shell is composed of a constant temperature cabin 20 and a high temperature reactor 7 integrally connected, and there are cavities in the constant temperature cabin and the high temperature reactor that communicate with each other. A sealed ball valve 5 is installed at the connection between the constant temperature cabin 20 and the high temperature reactor 7 on the reaction shell, which is used to control the communication or isolation between the constant temperature cabin 20 and the inner cavity of the high temperature reactor 7 .

[0034] One side of the constant temperature cabin body 20 is provided with a feed inlet 4, and is closed with a connecting flange 3. By opening the connecting flange 3 , materia...

Embodiment 2

[0043] Water gas shift reaction (CO+H 2 O→CO 2 +H 2 ) is an extremely important reaction process in the chemical industry. It is widely used in the ammonia synthesis industry and hydrogen production industry using coal, oil and natural gas as raw materials. It uses Co-Mo as the reaction catalyst, the reaction temperature is 350 ° C, and the reaction pressure is 4 MPa.

[0044] Take 50mg of Co-Mo catalyst and put it into the hanging basket, and feed N into the high temperature reactor at 300mL / min 2 , and send the hanging basket into the high-temperature reactor, heat up to the reaction temperature of 350°C, and put N 2 Switch to the reaction raw material gas (mixed by CO and vaporized water vapor), and discharge the N in the high-temperature reactor through the reaction gas outlet 2 , adjust the pressure to 4MPa to react. Gas chromatography was used to analyze the progress of the reaction. When the CO conversion rate reached 20%, the hanging basket was pulled into the cons...

Embodiment 3

[0046] Catalytic conversion of methane-carbon dioxide to synthesis gas (CH 4 +CO 2 →2CO+2H 2 ) can use a nickel-based catalyst, that is, 30% Ni loaded on γ-Al 2 o 3 on the carrier. Still use 300mL / min of N 2 As protective gas, according to the experimental process of Example 2, in CH 4 When the conversion rate was 10%, a small part of the catalyst was taken out for characterization. Then open the sealed ball valve, continue to put the catalyst into the high-temperature reactor for reaction, and wait for CH 4 When the conversion rate was 20%, a small part of the catalyst was taken out for characterization. Through the above-mentioned series of experimental investigations at different conversion rates, the investigation of the catalytic reaction and the entire catalytic reaction process at a certain conversion rate can be realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com