Catalyst for preparing 2-ethylhexyl alcohol through gas-phase hydrogenation of octenal and preparation method

A technology of ethyl hexanol and catalyst, which is applied in the field of catalyst and preparation of octenal gas-phase hydrogenation to 2-ethyl hexanol, which can solve the problems of easy pulverization of the catalyst and increase the use strength of the catalyst, and achieve high Effects of selectivity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

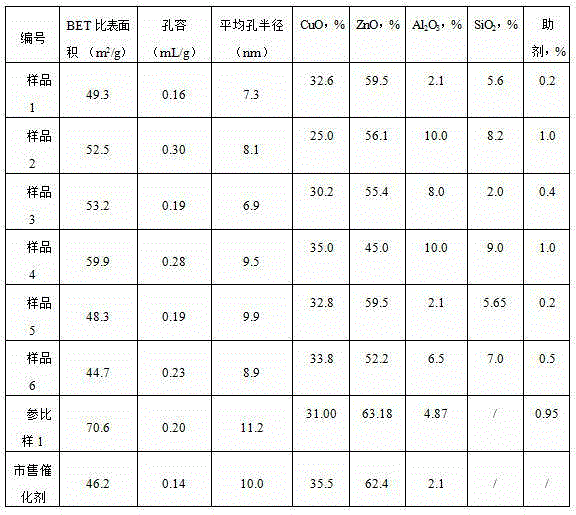

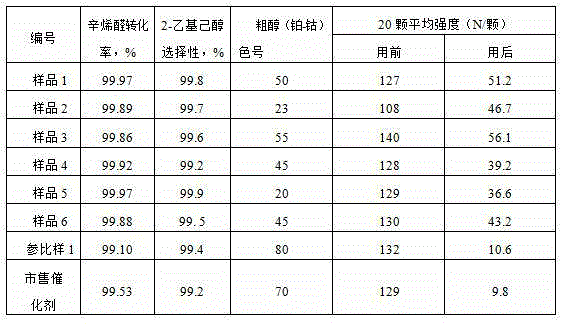

example 1

[0015] Put 4L of the prepared 1mol / L sodium carbonate solution into the precipitation tank with stirring, and add 55g of silica sol dropwise to the alkali solution at a temperature of 60°C, age at 65°C for 20 minutes, and take Mix 1000mL of 1 mol / copper nitrate solution, 1773mL of 1M zinc nitrate solution and 100mL of 1M aluminum nitrate solution to prepare mixed solution A, add solution A to the above solution at a uniform speed, neutralize for 30 minutes, and then age with stirring at 70°C for 30 Minutes, and then washed by concentration and washing, press-filtered to obtain a filter cake, dried, added 0.5 g of modification additives, and granulated. The dried particles were calcined at 320 ° C for 2 hours, and then pressed into tablets to obtain catalyst sample 1.

example 2

[0017] Put 4L of the prepared 1mol / sodium carbonate solution into the precipitation tank with stirring, add 80g of silica sol dropwise to the alkali solution at a temperature of 60°C, age at 65°C for 20 minutes, and take 1mol 790mL of copper nitrate solution, 1730mL of 1M zinc nitrate solution and 490mL of 1M aluminum nitrate solution were prepared as mixed solution A, and solution A was added to the above solution at a uniform speed, and the neutralization time was 30 minutes, and then stirred and aged at 70°C for 40 minutes. Afterwards, it was washed by concentrated washing method, press-filtered to obtain a filter cake, dried, added 2.5 g of modification additives, and granulated. The dried particles were calcined at 320° C. for 2 hours, and then pressed into tablets to obtain catalyst sample 2.

example 3

[0019] Put 4L of the prepared 1mol / sodium carbonate solution into the sedimentation tank with stirring, add 20g of silica sol dropwise to the alkali solution at a temperature of 60°C, and age at 65°C for 20 minutes to obtain 1M 950mL of copper nitrate solution, 1730mL of 1mol / zinc nitrate solution and 400mL of 1M aluminum nitrate solution were prepared as mixed solution A, and solution A was added to the above solution at a uniform speed, and the neutralization time was 30 minutes, and then aged at 70°C for 30 minutes, Afterwards, it was washed by concentrated washing method, press-filtered to obtain a filter cake, dried, added 1.0 g of modification additive, and granulated. The dried particles were calcined at 320°C for 2 hours, and then pressed into tablets to obtain catalyst sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com