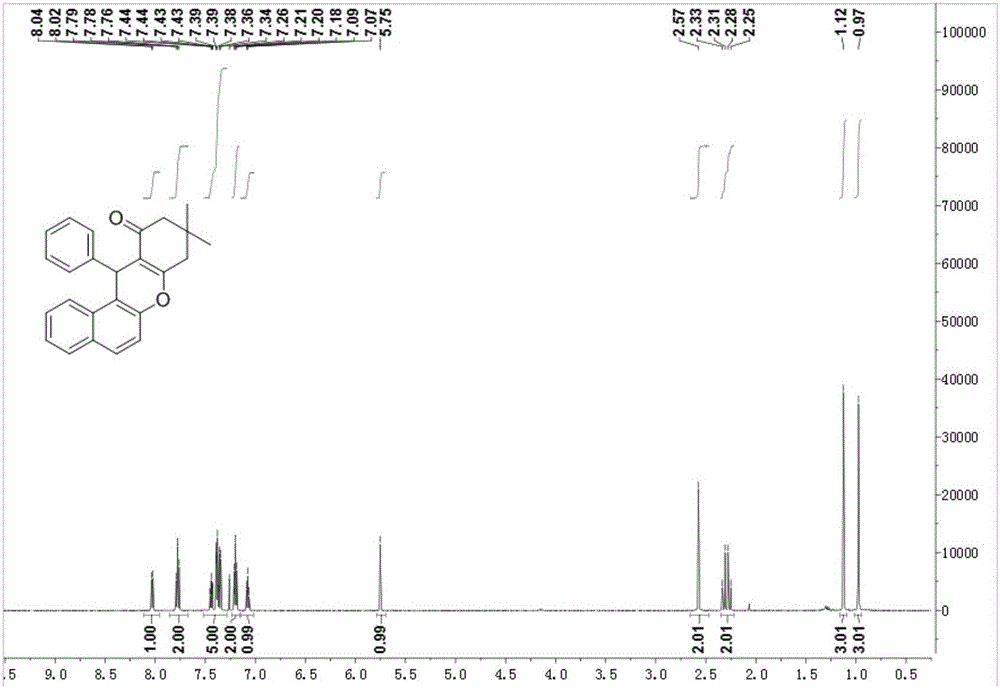

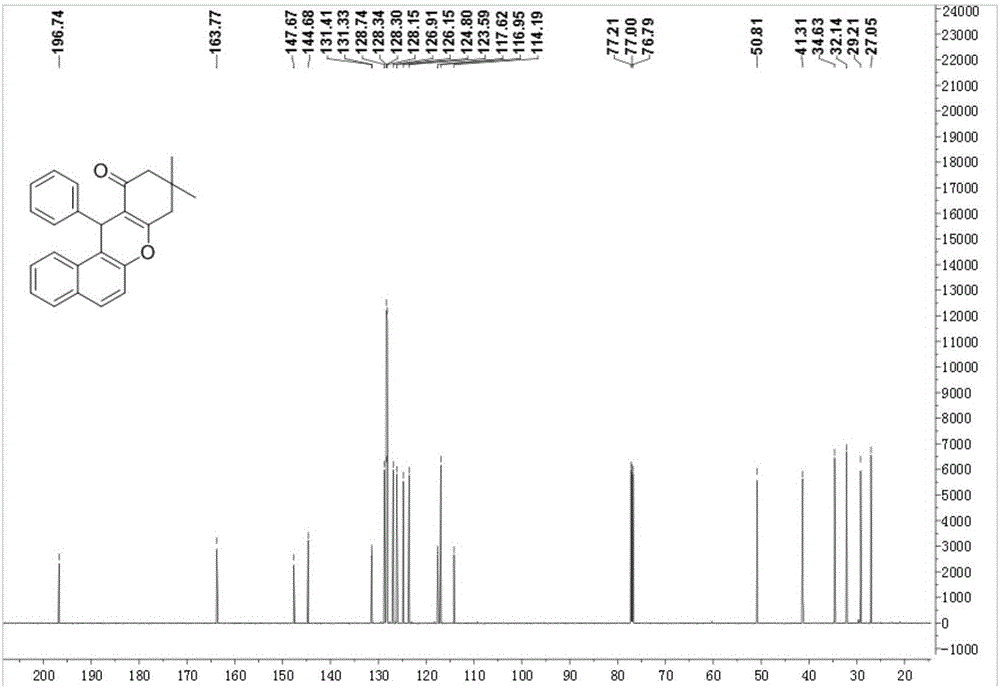

Xylan-base carbon-based solid acid and method for catalyzed synthesis of benzoxanthenes compounds by using same

A xylan-based carbon-based, solid acid catalyst technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, catalytic reactions, etc., can solve product separation difficulties, pollution of the environment, and corrosion of equipment. and other problems, to achieve the effect of high catalytic activity, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

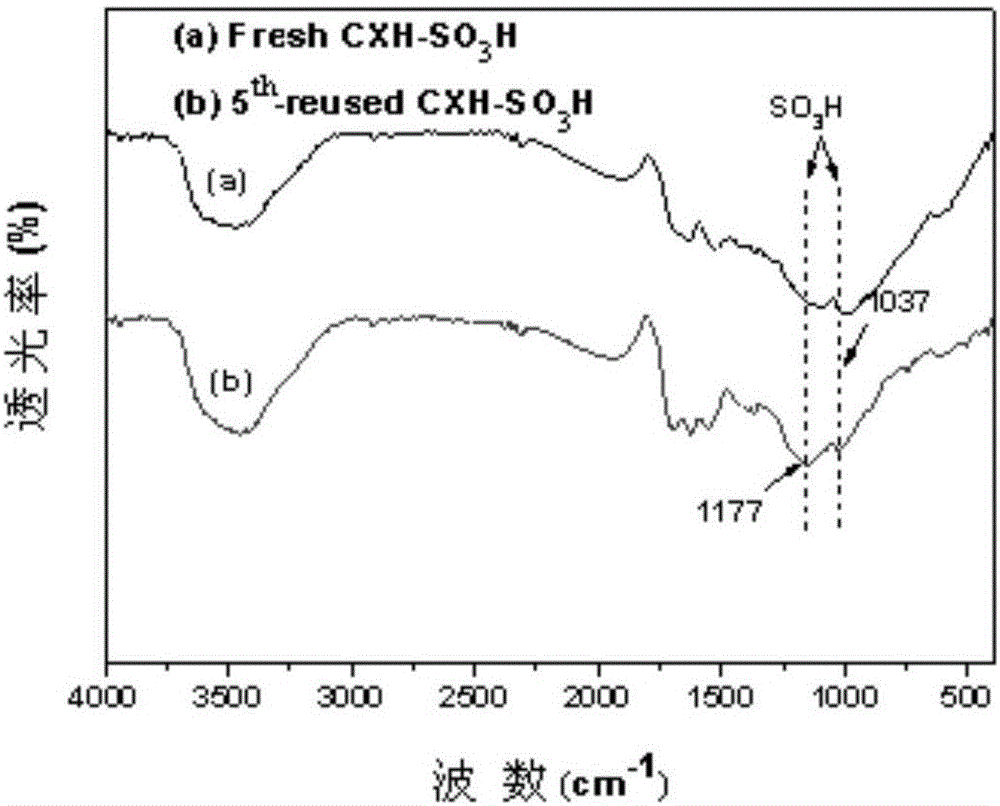

Embodiment 1

[0035] (1) Accurately weigh 3g of xylan hemicellulose in a crucible and place it in a tube furnace. Under a nitrogen atmosphere, heat it from room temperature to 200°C and keep it warm for 180min. After the reaction is completed, cool it to room temperature to obtain a black powdery incomplete carbonization product of xylan hemicellulose;

[0036] (2) The product obtained in step (1) is mixed with concentrated sulfuric acid in a ratio of 1:30 (g:mL) and then placed in a reaction kettle with a polytetrafluoroethylene liner. Under a nitrogen atmosphere, the reaction The system was heated from room temperature to 250°C for 12 hours;

[0037] (3) Add the reaction mixture obtained in step (2) dropwise to 1000 mL of ice-water mixture under constant stirring. After the dropwise addition, wait for the solution to cool to room temperature, filter, and fully wash the solid with hot water (>80°C) The substance was dried until the eluent was neutral, and then vacuum-dried at 80° C. to ob...

Embodiment 2

[0039] (1) Accurately weigh 3g of xylan hemicellulose in a crucible and place it in a tube furnace. Under a nitrogen atmosphere, heat it from room temperature to 350°C and keep it warm for 90 minutes. After the reaction is completed, cool it to room temperature to obtain a black powdery incomplete carbonization product of xylan hemicellulose;

[0040] (2) The product obtained in step (1) is mixed with concentrated sulfuric acid in a ratio of 1:30 (g:mL) and then placed in a reaction kettle with a polytetrafluoroethylene liner. Under a nitrogen atmosphere, the reaction The system was heated from room temperature to 150°C for 15 hours;

[0041] (3) Add the reaction mixture obtained in step (2) dropwise to 1000 mL of ice-water mixture under constant stirring. After the dropwise addition, wait for the solution to cool to room temperature, filter, and fully wash the solid with hot water (>80°C) The substance was dried until the eluent was neutral, and then vacuum-dried at 80° C. t...

Embodiment 3

[0043] (1) Accurately weigh 3g of xylan hemicellulose in a crucible and place it in a tube furnace. Under a nitrogen atmosphere, heat from room temperature to 400°C and keep it warm for 60 minutes. After the reaction is completed, cool to room temperature to obtain black powdery incomplete carbonization product of xylan hemicellulose;

[0044] (2) The product obtained in step (1) is mixed with concentrated sulfuric acid in a ratio of 1:30 (g:mL) and then placed in a reaction kettle with a polytetrafluoroethylene liner. Under a nitrogen atmosphere, the reaction The system was heated from room temperature to 100°C for 18 hours;

[0045] (3) Add the reaction mixture obtained in step (2) dropwise to 1000 mL of ice-water mixture under constant stirring. After the dropwise addition, wait for the solution to cool to room temperature, filter, and fully wash the solid with hot water (>80°C) The substance was dried until the eluent was neutral, and then vacuum-dried at 80° C. to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com