A method of using liquid metal electric discharge machining spherical die

A technology of liquid metal and electric discharge machining, which is applied in the research of electric discharge technology and the field of electric discharge processing, can solve the problem of not fundamentally solving the problem of electrode loss, etc., and achieve the effect of solving errors, improving processing efficiency, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

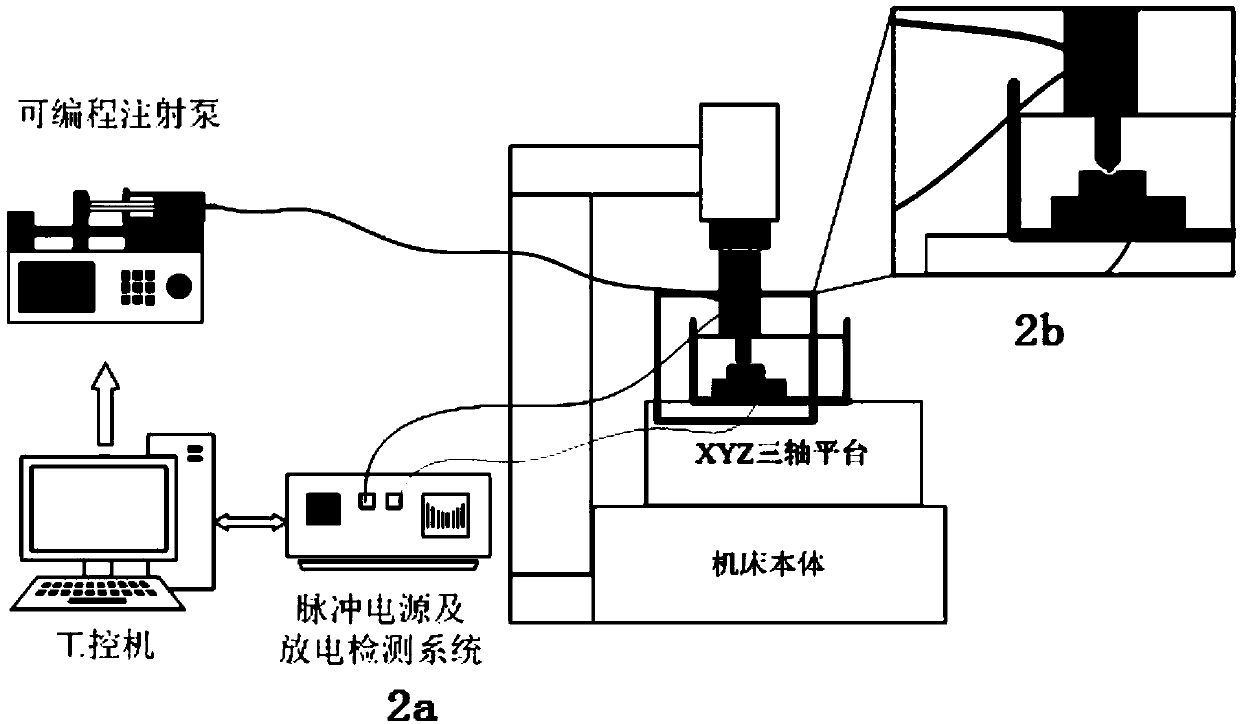

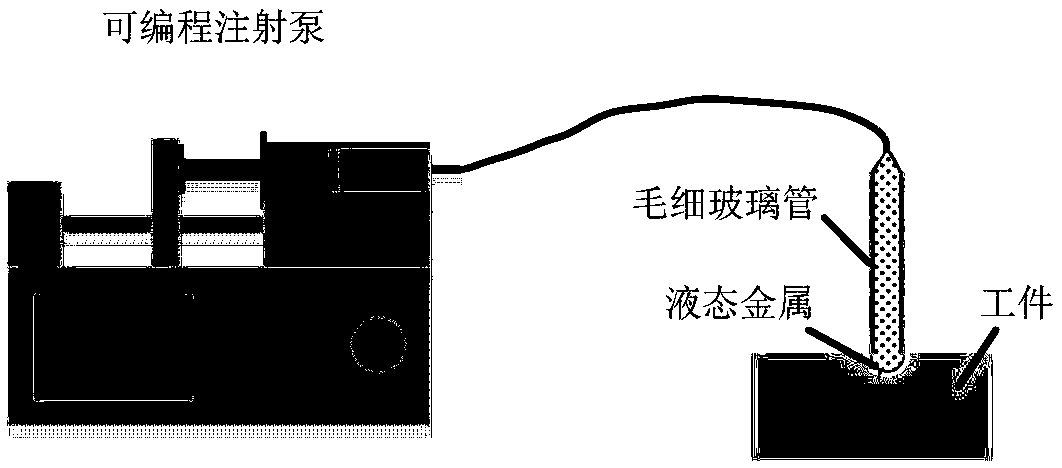

[0029] Such as figure 1 and 2 As shown, the liquid metal electrode processing device includes an electric discharge machine tool and a liquid supply system. Among them, the processing machine tool is preferably a three-axis CNC EDM machine tool, including machine tool, industrial computer, pulse power supply, electrode, workpiece and other components; the liquid supply system includes liquid metal, plastic catheter, programmable syringe pump, capillary glass tube and other components composition.

[0030] The machine tool is controlled by an industrial computer, driven by a high-precision servo motor, and the feeding accuracy is 1 μm; the pulse power supply can provide pulse voltage with adjustable cycle and frequency, and is equipped with a discharge detection device, which can detect the current discharge state between the two electrodes , and feed back the detection signal to the industrial computer for processing.

[0031] In the liquid supply system, the liquid metal i...

Embodiment 2

[0033] Embodiment 2 Concave mold one-shot molding process

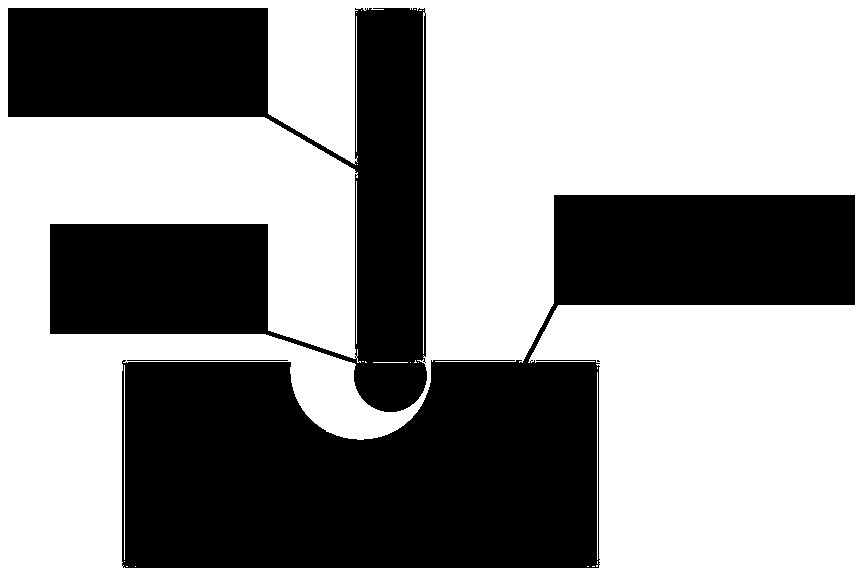

[0034] Using the solution in Example 1, for a spherical die with a small diameter (0.1mm image 3 shown.

Embodiment 3

[0035] Embodiment 3 Multi-scanning processing of die

[0036] Using the scheme of Example 1, for spherical concave molds with large diameters (arc radius SR Figure 4 shown in a1-4c2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com