Anticorrosion surfacing interior joint coating method for submarine pipeline

A seabed pipeline and seam filling technology, which is applied to pipeline systems, welding equipment, arc welding equipment, etc., can solve the problem of inability to ensure the consistency of the mechanical properties of the carbon steel base material, and does not involve seabed pipeline anti-corrosion surfacing welding-free joint methods, potential Corrosion and other problems, to reduce the comprehensive cost and the difficulty of pipeline welding operations, avoid the risk of joint corrosion, and ensure the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

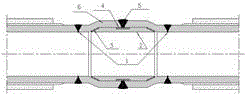

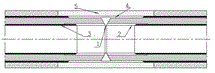

[0032] The invention discloses a seabed pipeline anti-corrosion surfacing welding internal repair method. Taking the inner pipe of the seabed water injection pipeline Φ245*18mm (executive standard: API 5L-PSL2) X60 grade seamless steel pipe as an example, the specific implementation steps are as follows:

[0033] (1) Mechanical grinding steps of pre-surfacing welding parts: use an angle grinder to grind to ensure that the pre-surfacing welding and nearby areas are exposed to bright white metal;

[0034] (2) Corrosion-resistant alloy surfacing steps:

[0035] (1) Overlay welding consumables: Ni625 welding wire;

[0036] (2) Starting from the end of the steel pipe, the first layer of surfacing welding by the automatic pipe end inner wall surfacing welding machine has a thickness of 1.2-1.5mm and a surfacing width of 80mm;

[0037] (3) Starting from the end of the steel pipe, the second layer of surfacing welding by the automatic pipe end inner wall surfacing welding machine has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Dilution degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com